Bonding the pipelines is used to lessen the risk of electrical and fire hazards in households once the pipes become electrically energized.

Some places implement codes about pipes bonding, but can you bond the gas and water pipes together? We've researched this topic, so you don't have to!

The answer is yes. When using metal pipes for gas and water plumping, the pipelines should remain at zero voltage to protect the electrical system and the person handling the plumbing works.

Bonding the gas and water pipes will help carry the electricity in your lines back to its source to prevent fire hazards, explosions, and electric shocks.

Bonding gas and water pipes can be easy, but you have to equip yourself with the correct knowledge to prevent making mistakes when doing so.

Don't worry! We will get into further details on how you can bond your gas and water pipes, so read until the end of this post to know more.

How To Bond Gas And Water Pipes Together?

Electricity is one of the most beneficial things to mankind nowadays, but it can also carry out health hazards when not handled properly.

Even a simple low voltage electric surge can cause you harm; bonding is necessary to prevent problems caused by electricity.

Bonding your metallic gas and water pipes will give the fault current a way back to the main earth terminal. This method is commonly used in old buildings and households or where gas and water lines are made of metal pipes.

If you use plastic pipes for your water line but metal pipes where the electrical installation begins, you still need to do bonding.

Bonding terminals or screws are commonly installed in electrical boxes for easier bonding. If your electrical boxes do not have bonding terminals, you can use a mechanical lug, a bolt, and a nut connection to make a main earth terminal.

Although it is strongly advised to let a professional do the bonding, we've listed down what you will need and how you can do bonding on your own.

Process for Bonding Pipes

What you need:

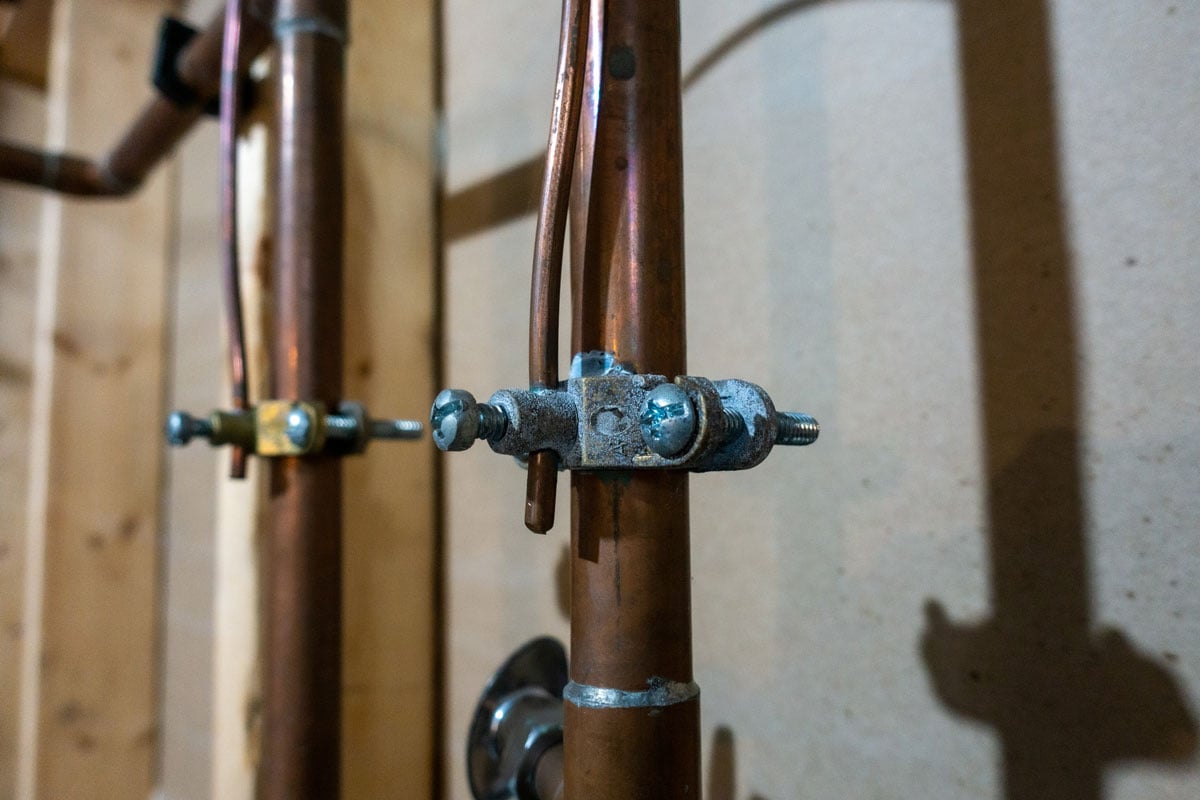

- Bonding clamps

- copper wire

- screw

To bond your gas and water pipes together, here is a step-by-step guide:

- Look for the point of entry of your gas and water pipes. The bonding must be done within 600mm from the meters or above the dielectric material.

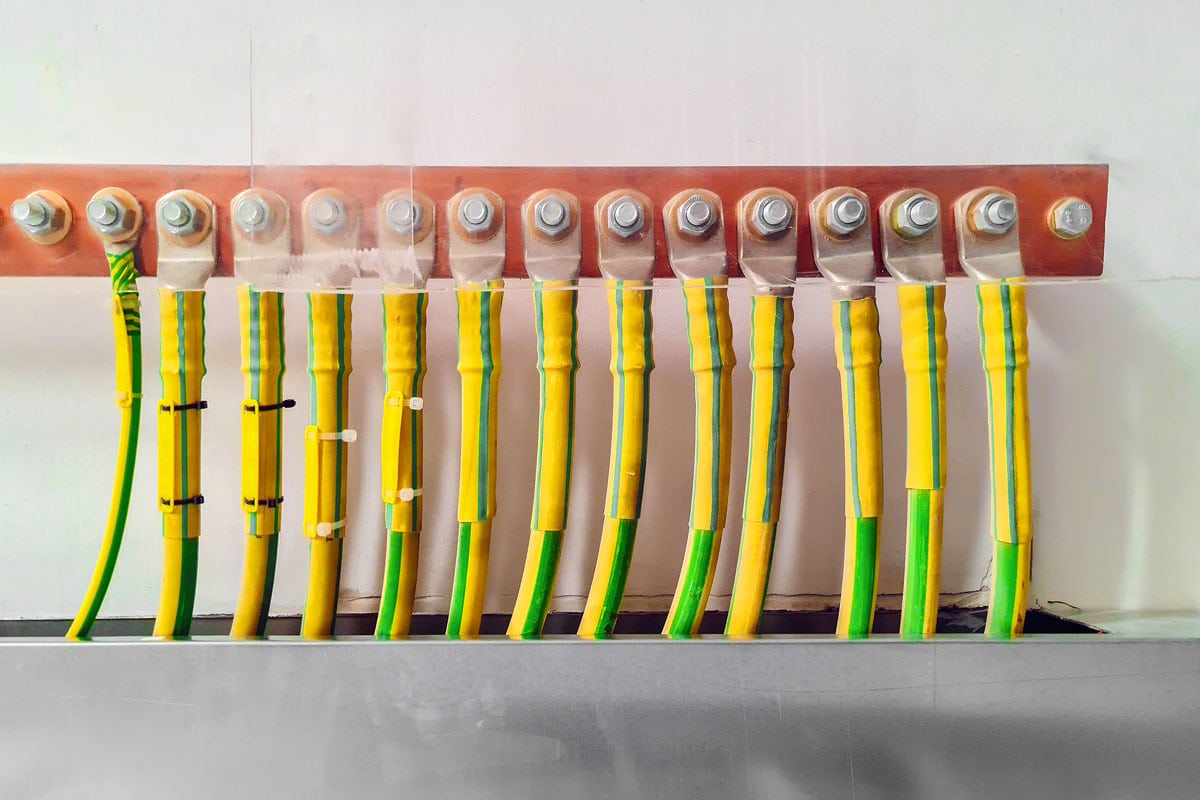

- Using a bonding clamp and a 10mm green and yellow copper wire, bond the pipes starting from your main bonding conductor, which is your water pipe and your gas pipe. If the pipes are insulated, remove the insulation materials from the part where you will place the bonding clamp.

- Connect the end of the copper wires to the bonding clamp and the other end to the main earth terminal. Make sure that you do not tighten the clamp too much or place it near any soldering joints to avoid leakage.

When bonding paint-coated pipes, make sure to remove the paint on the area where you will place your bonding clamp to ensure that the bonding will work properly.

Check out this insulated copper wire on Amazon.

Bonding vs. Earthing vs. Grounding

Although bonding, earthing, and grounding seem to serve the same purposes, there is a slight difference between these three methods. Let's see how these methods work and what separates them from one another.

Bonding Method

In a simpler context, bonding connects two conductors that tend to be electrically energized. It can be done on metal pipes, wires, or a combination of wire and metal pipe.

This method ensures that the conductors will carry the same level of voltage to prevent electrical buildups.

When the pipes are not bonded and you touch them simultaneously, your body will act as the path of equalization. Preventing it from happening is the primary purpose of bonding.

The bonding method is commonly used for bonding gas and water pipes together to create a low electrical path.

Earthing Method

On the other hand, earthing connects one electrically energized conductor with a dead part or a non-current conductor to direct the electrical charge back to the earth.

This method reduces the risk of experiencing electric shock when you make contact with a non-current conductor. A ground rod or other electrodes are buried in the ground to release the electric charge to the earth.

The two most commonly used types of earthing at home are plate earthing and pipe earthing.

Plate Earthing

Plate earthing is burying a galvanized copper or iron in a depth of not less than three meters in a vertical position. The plate will act as the conductor to release the electrical charges back to the earth.

Pipe Earthing

On the other hand, pipe earthing uses a galvanized steel pipe or rod as a conductor. Depending on the soil condition, the pipe must be vertically buried in the ground.

See this galvanized steel pipe on Amazon.

Grounding Method

Grounding is a method used to create an alternate path for the fault current to flow if the system makes contact with dangerously higher voltages, such as lightning strikes.

Grounding has two methods you can apply, depending on the type of grounding you need.

It is called an electrical circuit/system grounding when a single conductor is intentionally connected to the ground. In contrast, when all metal conductors connected to equipment are connected to the earth, it is called equipment grounding.

Using this method, you can protect yourself, your appliances, and the electrical system from a sudden electric surge.

Can You Bond Plastic Pipes With Metal Pipes?

If the entire pipeline is plastic, you cannot use it as a bonding conductor with metal pipes since plastic pipes cannot carry electricity.

Just like other non-metal materials such as wood and rubber, plastic is considered an insulator because it prevents the electrical current from passing through. It does not contain the same components that metal pipes have. Therefore, you cannot bond plastic pipes such as PVC and PEX with galvanized or copper pipes.

However, if the pipe coming from the main installation is made of metal, you can perform bonding on the metal pipe near the main electrical installation box, not on the plastic pipe.

Should I Insulate Bonding Wires?

The answer is yes. It is a must to keep bonding wires insulated. Unlike grounding wires that may need insulation to prevent them from becoming slippery, indoor bonding wires such as copper need insulation to prevent them from contacting other conductors.

By insulating the bonding wires, you can prevent electrical leakage and other environmental hazards caused by bare wires. Although bare copper wires still exist in the market, you can purchase insulated copper wires, so you don't have to insulate the wires by yourself.

Wrapping It Up

To summarize, bonding is a method you can use to make an alternate route for excess electricity to pass through. Doing the bonding method will not only prevent fires and other electric hazards but can also keep you safe from electric shocks.

Despite bonding appearing pretty simple to do, you can hire a professional electrician to do it for you to make sure that you will not make things worse.

Electricity is beneficial but can also be fatal when you perform electrical-related methods without the proper knowledge and experience.

Before you go, don't forget to check these posts, too!