If you've decided to use the AC of your car, you might want to know if it's possible to bypass the AC’s compressor by installing a shorter serpentine belt. You’ve come to the right place, for we have researched this question, and we have the answer for you.

Yes, in most cases, you can bypass the compressor in your car by installing a shorter serpentine belt.

Let’s talk more about this method to turn off the AC of your car in the succeeding sections. Learn to bypass the compressor and get the right serpentine belt length below.

Read on!

What is a serpentine belt?

Older model cars have several belts that connect to the engine. Each belt powers one engine accessory, like the compressor for the AC or the alternator.

Multiple belts inside the engine compartment mean they must be thinner or consume a lot of space. However, thinner belts are less efficient because you cannot apply as much tension on a thinner belt since too much pressure can break one more easily.

Moreover, a thinner belt has less surface area that comes into contact with the accessories' pulleys, which means there is a higher likelihood of slipping. Slipping shortens the belt's lifespan because it will rub against the side of a pulley or the engine's walls.

Thinner belts become looser and quicker over time, leading to diminishing performance. The need for less tension on the thinner belts also makes having high-torque accessories on the car problematic.

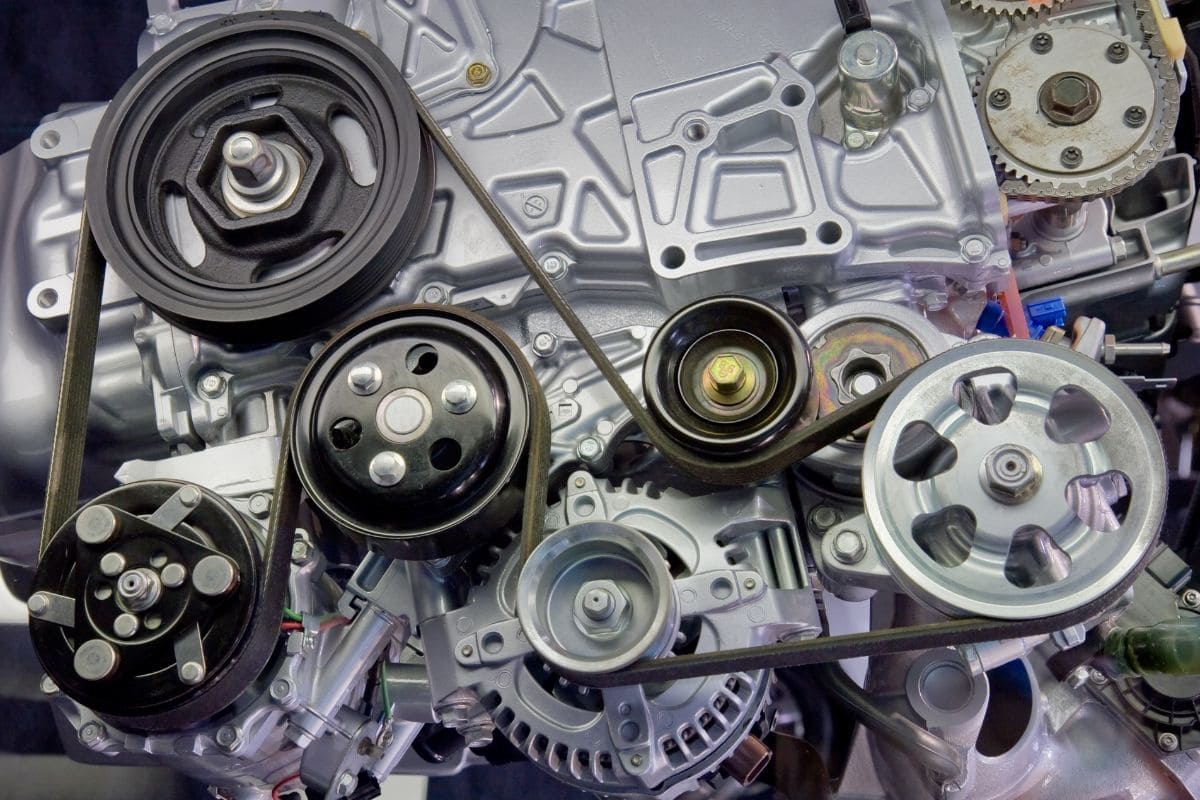

Serpentine belts eventually replaced thin, multiple straps inside the engine bay, and over time, engine designs no longer use various belts.

Serpentine belts use advances in rubber technology that are not possible with thinner straps. They are more comprehensive and have grooves that increase the surface contact area to improve grip and stability.

Their width allows engineers to implement a tensioning mechanism or a tensioner in newer engine designs. Tensioners push on the serpentine belt to increase its tension and improve grip and torque on the pulleys. A serpentine belt isn't at risk of breaking with more significant tension because it is broader, granting it a higher breaking point than traditional thinner belts.

How does a serpentine belt work?

A serpentine belt passes through the pulleys of various sizes that power your car's accessories. The serpentine belt draws rotational energy from the crank pulley and transfers it to the accessories needing it.

The serpentine belt typically has grooves on one side and a smoother opposite side.

The side with grooves provides power to accessories that need higher torque, while the smoother side powers accessories that need less torque. The serpentine belt also passes through idler pulleys.

Idler pulleys are responsible for redirecting the serpentine belt so that the appropriate side will pass through a pulley. It also creates the ideal angle for connecting the belt and the pulley.

Can I bypass the AC compressor with a shorter belt?

In most cases, yes.

However, bypassing the compressor pulley still redirects the serpentine belt into the path of the compressor’s pulley. You cannot avoid the compressor pulley unless you uninstall the compressor completely.

Moreover, the path of the serpentine belt going to a pulley must retain a specific angle to maintain the level of tension and friction that it makes with a pulley. If bypassing the compressor causes the serpentine belt to lose too much angle from its connection to a pulley, that connection with a pulley could have less torque and less stability. This can be a problem if the accessory that the pulley powers requires high torque.

And if you uninstall the compressor, you need to decide whether you’d like to completely get rid of the AC functionality of your car or not. Removing the compressor will render your AC system completely useless.

However, getting rid of your AC compressor provides you with additional space inside the engine bay that you can use. A ProCharger can replace the compressor—it will also draw power from the serpentine belt—and provide your engine with a boost of energy.

If you don’t plan to install a ProCharger and the compressor’s pulley is in the path of the serpentine belt, then you could uninstall the compressor and replace it with an idler pulley. This replacement will ensure that the serpentine belt maintains the same operating angle as the accessories it powers.

You will still need a smaller serpentine belt unless the idler pulley is the same size as the compressor's pulley.

How to determine the length of the serpentine belt that you need

When you bypass the compressor, you must also replace the belt. Since you’re using the belt for the same system, all you need to change is the length. You can bring the old belt to your auto store and tell them you need a belt of the same type but a different size.

We have the steps to help you get the new length of the serpentine belt that you need in the sections below.

Alternatively, you can give them the PK number of the belt.

What is the PK number of a serpentine belt?

The PK number is a global standard for indicating the size of the belt. Since this is a worldwide standard, there are metric measurements in the PK number, so note whether you’re looking at a metric measurement.

You’d know that you’re looking at the PK number because it has “PK” within the first three to four characters. It is also printed close to or beside the manufacturer’s part number.

There are three sets of information on the PK number. The first information is before “PK,” and the third is after.

The first set of characters of the PK number indicates the number of ribs on the belt. If you see 7 or 10 on the first set of characters, then that is the number of ribs that the belt has.

The next set of characters is “PK.” “P” means using a metric designation, while “K” is a belt for automotive use.

The last set of information is the length of the belt in millimeters. Thus, if you have 1204 after “PK,” you have a serpentine belt with a length of 1204 millimeters.

Determining The Length Of Serpentine Belt That You Need

- Park your car on level ground.

- Place the transmission into Park (P) and enable the parking brake.

- Make sure the car’s engine is excellent before measuring. You’d be touching parts of the engine. A hot engine can burn you.

- Use painter’s tape to fasten one end of a cotton string or twine on one of the pulleys. Cotton has a minimal stretch, which is essential.

- Run the string through the pulleys on your engine that the serpentine belt will pass through. Your line must move through the same ridge. If you start at the first or second ridge, all the pulleys it will pass through should be on the first or second ridge.

- Use a breaker bar to loosen the tensioner. Most tensioners have a “min/max” marking that tells you the minimum and maximum length of belt you need. When you mark the length of the string, you should set the tensioner to “min” to give the belt room to expand.

-

- Belts naturally expand as they wear. Once the tensioner reaches the “max” position, you need to replace the belt.

- Measure the total length of the string in millimeters. This is the effective length of the belt.

-

- To get the outside length, add 14 to the total length.

- Most serpentine belt manufacturers have a 3-millimeter tolerance. If the exact length is unavailable, you can get one that is +/- 3 millimeters of your target length.

- Count the number of ribs that you need on the serpentine belt.

- Put the two pieces of information together and have your PK number.

Dayco 6PK2135 Serpentine Belt is available on Amazon through this link.

ScotchBlue Original Painter’s Tape is available on Amazon through this link.

NEIKO Drive Extension Breaker Bar is available on Amazon through this link.

Alternative Way To Disable The Compressor

There might be a situation where you cannot immediately remove the compressor, but you want to turn it off directly to maximize the power you’re getting from the engine.

Removing the compressor involves the removal of the rest of your AC system, which can take time to complete.

Another way to turn off the compressor—if you don’t plan to uninstall it yet—is to disconnect the power harness that goes to the compressor clutch.

This will prevent the compressor clutch from responding to the AC switch. Anyone can turn the AC switch on, but the compressor clutch will not engage the compressor pulley and draw power from the engine.

Conclusion

Bypassing the AC compressor can be done in two ways. However, it can involve slightly more work if you do not want to affect the performance of the other accessories in your car.

If you enjoyed reading this article, you might find the articles below equally enjoyable to read:

Scroll vs. Reciprocating: What Compressor Is Best For Your Needs?