When replacing a flame sensor, you might find that the replacement isn't at the same angle or length as the original. You may wonder if bending or cutting the rod is okay to make it fit. Luckily, we have done the research for you, and here is what we found.

Yes, flame sensors can be bent or cut when necessary. Use a side-cutter or hacksaw to cut the flame sensor to the correct length. Many universal flame sensors come with angle guides and protective sleeves to help you bend them safely.

The flame sensor generates an electric current to verify a fire burning inside the furnace. A current is discharged from the sensor while the gas valve is opened to initiate combustion. This allows the sensor to detect the presence of heat from a flame. Keep reading to get detailed information about flame sensors.

Can You Cut Or Bend A Flame Sensor? Should You?

A flame sensor can be cut or bent. To ensure that the sensor rod's end is positioned more appropriately in the pilot light, you can give it a slight bend (about 20 degrees). However, be careful to avoid damaging the ceramic insulation in any way. The burners will have a more reliable ignition as a result of this.

By bending the flame sensor, the flame rods will be arranged so that one end of each flame rod is in direct contact with the flame of the burner, while the other end of each flame rod is connected to the ignition board of the furnace. You need a side cutter, hacksaw, or bolt cutter to cut a flame sensor.

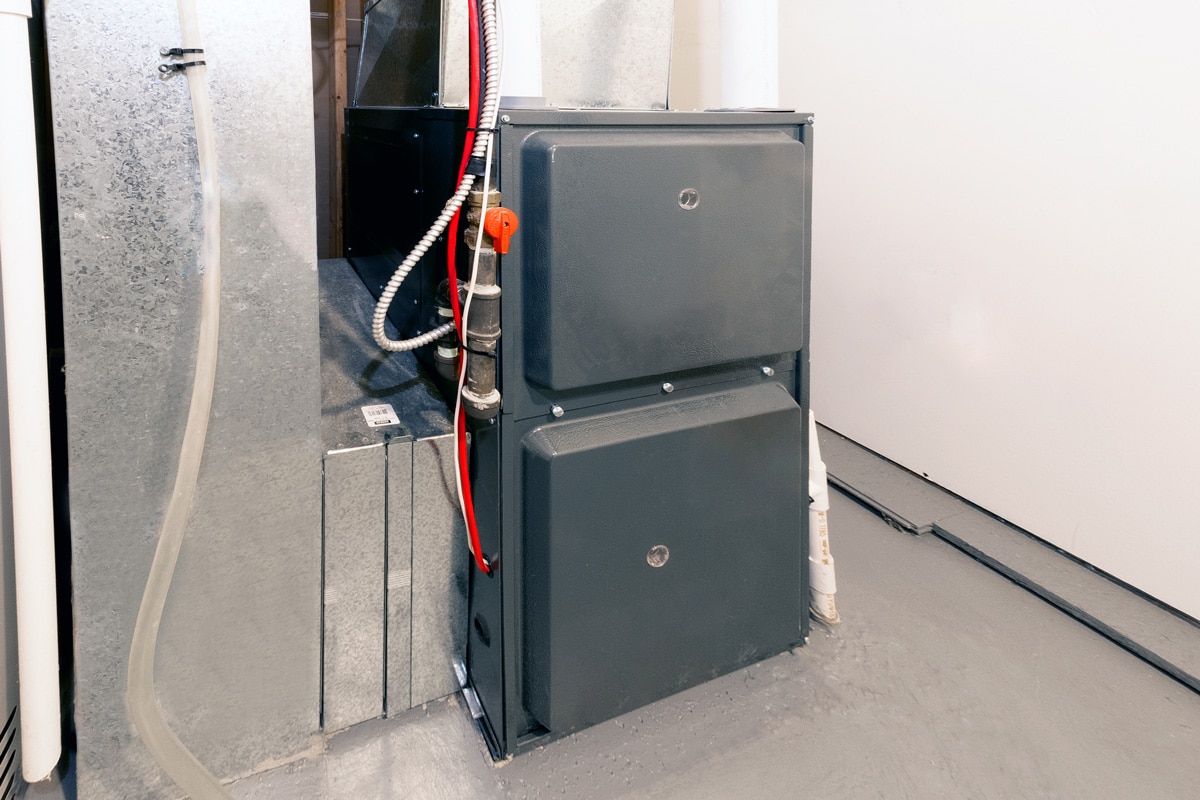

A flame sensor can be found inside the furnace. It identifies and verifies whether or not the furnace is ablaze with a flame from within. It performs its function by determining whether or not the furnace contains an active flame. When the flame is detected by the sensor and the furnace is operating normally, the heating process continues.

However, the furnace automatically turns off if the flame sensor does not detect the presence of a flame within ten seconds of the gas valve being opened.

Click here to view this flame sensor on Amazon.

Click here to see these side cutter pliers on Amazon

Many universal flame sensors are designed to be bent or cut and will come with guides to help you do so. Check out the video below to see the process for the Emerson White-Rodgers flame sensor:

What Metal Is A Flame Sensor Made Of?

The majority of flame sensors are made up of a rod made of stainless steel that is partially covered in porcelain. Flame sensors have no effect by themselves. There is not a single moving part, and there are no switches. Once the sensor has been connected to a control module, the module provides an alternating current voltage to the sensor.

How Do You Test A Flame Sensor?

To do a test on the flame sensor, follow these steps:

Step 1: Turn Off The Device

Ensure the furnace is well grounded. You can do this by powering down the furnace and getting an ohm reading between the neutral and the burner assembly/manifold. You should only read a few ohms of resistance at most. The lower the ohm reading, the more grounded the component is.

Step 2: Make The Necessary Connections

To ensure the polarity is correct, connect the hot (L1) terminal to the hot terminal and the neutral (N) terminal to the neutral terminal. The rod must be positioned so that the flame will cover it.

Check the instructions provided by the manufacturer because many boards contain test pads that read in DC volts, a light to indicate a low flame reaction, or a display that shows a flame response.

Get a meter that reads in micro-amps. Use a decent quality meter to ensure the leads are in the correct positions. Connect the leads in series. This implies you have to separate the wire from the rod, connect one-meter lead to the rod and the other to the wire taken from the rod.

Step 3: Check The Readings

When the burners start, you should see a reading of 0.5 to 10 micro-amps, depending on the furnace. The majority of people get readings between two and six. However, check the manufacturer’s specs.

How Many Volts Is A Flame Sensor?

If a voltmeter is used to measure the voltage between the flame sensor wire and the burner, the flame sensor voltage should fall within 40-80 volts AC.

If the voltage exceeds the acceptable range, there will be no sufficient electrical pressure to force the current into the flame.

Click here to see this multimeter on Amazon

Should I Clean Or Replace the Flame Sensor?

Cleaning and maintenance of the furnace should be performed on a seasonal basis to extend the life of a flame sensor.

Give the sensor of your heating system a thorough cleaning at least once a year. You can avoid having to call for emergency heating services in the middle of the winter, even if your heating system seems to be operating smoothly.

However, the safety of your system is of the utmost significance; hence, it is always preferable to be on the safe side rather than regret and replace the flame sensor if it is not functioning correctly.

You should replace the flame sensor every two or three years as a preventative measure, even if it is in good operating order and performing as it should.

Why Do Flame Sensors Fail?

A flame sensor may malfunction or fail for different reasons. A dirty sensor is the most prevalent. Metal will rust if left exposed to the byproducts of any combustion for an extended period.

As a result, since flame sensors are metal constructed, they are susceptible to rust, preventing them from detecting the flame effectively.

Another potential reason a flame sensor may fail is a sensor that is either faulty or has an insulator break. A short in the component's electrical wiring may have severed its connection to the control board.

What Happens When a Flame Sensor Goes Bad?

If the flame sensor is malfunctioning, you should have a professional HVAC technician check your system. If the flame sensor goes bad, your furnace will keep releasing potentially deadly gas even when there's nothing to light it. Without a clean or malfunctioning flame sensor, the heating system turns off if it senses that a flame isn't present.

After three consecutive shutdowns, most furnaces lock out the ignition for safety. Constantly tampering with a defective flame sensor in a furnace is highly inconvenient and can lead to problems in other furnace components and a decrease in the system's overall performance.

A flame sensor helps ensure the furnace doesn't call for gas if the flame is lit incorrectly. Anyone who is inside the house is protected from the dangerous accumulation of gas thanks to this measure. Additionally, it helps to ensure that the gas is not being wasted by being run while not being used.

Explosions can be avoided in the home by minimizing the gas inside, which reduces the likelihood that the house will become filled with gas and that a spark will ignite the gas.

How Many Ohms Should A Flame Sensor Read?

When measured with an ohmmeter, the flame sensor should show a reading of 0 ohms; nevertheless, a reading of 1 to 2 ohms is acceptable. On the other hand, when a flame is present, the resistance between the flame sensor and the ground increases to many thousand times that value.

When no flame is present, the resistance between the flame sensor and the ground should be infinite or at least several hundred megaohms. A standard multimeter would not be needed to measure such a high resistance value.

To Wrap Up

It is okay if you think your flame sensor needs to be cut or bent. You will need a side cutter, hacksaw, or bolt cutter to cut a flame sensor. The flame sensor is an essential safety feature in a furnace. So, when the sensor doesn't work, you can also replace it.

If you enjoyed reading this post, here are similar articles you may like:

Where Is The Flame Sensor On A Carrier Furnace