Are you wondering how long it takes for expanding foam to dry? You are on the right page! We researched this topic thoroughly and have information to share with you.

The time it usually takes for expanding foam to completely dry so that no moisture remains is between 5 and 60 minutes. Depending on the substance of the foam and the site conditions, the full cure may take between 8 and 24 hours.

In this article, we will delve deeper into expanding foam, especially its drying and curing time. We will also share how to apply it, the dos and don’ts of it, and more. So keep on reading.

What is Expanding Foam?

Expanding foam is a product made to expand and harden when it comes into contact with air. It often comes in canisters with spray nozzles, enabling a wide range of applications for the foam.

The majority of companies clearly state the recommended usage on the packaging of the product, although some customers may think outside the box when it comes to uses for this material.

Traditionally, this product is kept under intense pressure. The pressurized fluids spurt out when the spray nozzle is activated, and they begin to expand. The contents appear foamy as they expand and begin to harden. Because this foam can expand enormously, users must take caution when applying it to avoid applying too much.

Drying and Curing Time of Expanding Foam

The time it takes for the foam to cure or harden depends on the composition of the product, temperature, humidity, how much foam is being sprayed, and other factors.

At normal temperatures and humidity levels, insulating foam sealants typically dry quickly. First, the foam surface dries out, and then the foam body progressively dries out as well.

It takes longer for the foam to completely cure the thicker application. The curing process can be accelerated by misting the substrate between layers of foam with water.

When the foam is "tack-free" (dry or no longer sticky on the surface), you can trim the excess foam. Usually, it takes the foam between 5 and 60 minutes to become tack-free.

The full cure may be accomplished in anywhere from 8 to 24 hours. When it comes to exact curing times, refer to the product label and directions.

Some examples of expanding foam products are shown below with their drying and curing times:

- Great Stuff: tack-free - 5 to 15 minutes; fully cured - 8 hours

Click here to see this Great Stuff on Amazon.

- Loctite Tite Foam: tack-free - 8 minutes; fully cured - 24 hours

Click here to see this Loctite Tite Foam on Amazon.

- Red Devil: tack-free - 10 minutes; fully cured - 24 hours

Click here to see this Red Devil on Amazon.

How To Use Expanding Foam?

Below are the steps for applying expanding foam:

1. Clean The Area

Sweep away any dust or loose objects in and around the area with a sizable, dry paintbrush. Spray some water over the area once it has been cleaned. This will assist in the foam's even curing, because expanding foam needs moisture to cure.

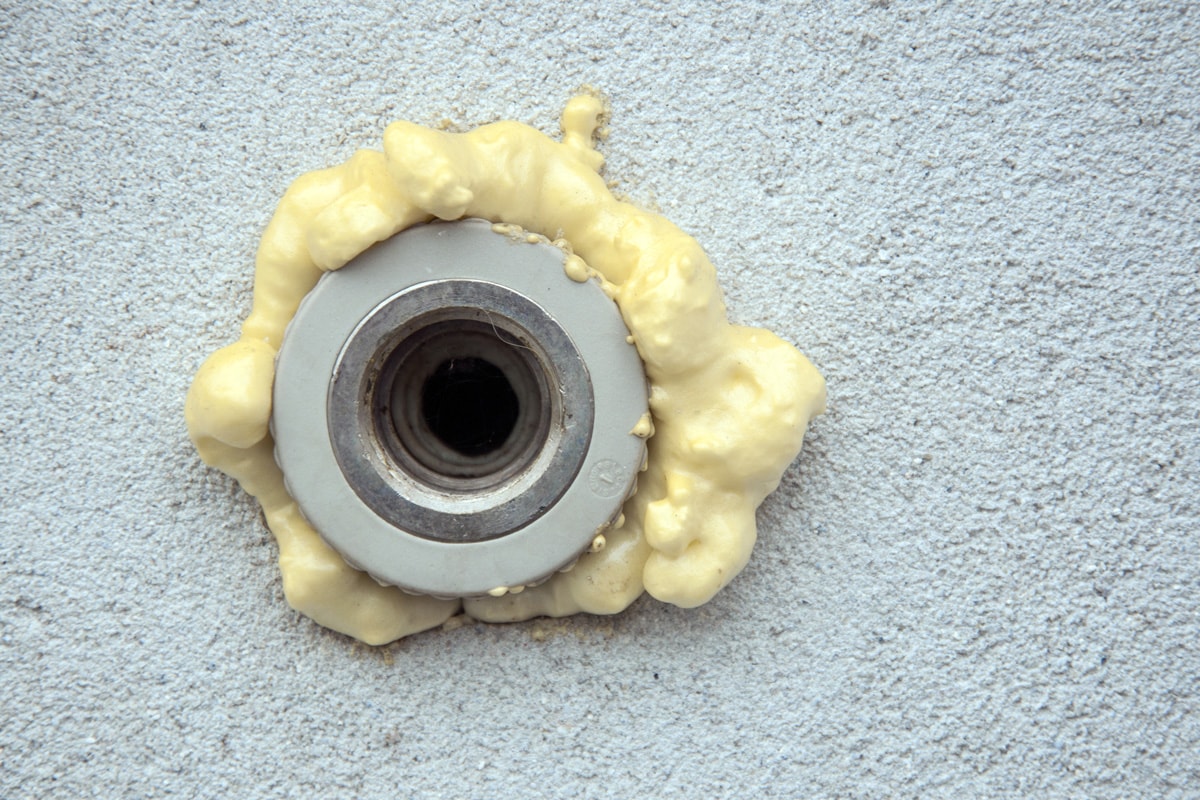

2. Spray The Expanding Foam

Read the manufacturer's directions before putting the expanding foam on the surface. It is crucial to use protective gloves when working with expanding foam, since it can irritate the skin. The nozzle that comes with the product is used to apply the expanding foam.

Shake the can well after attaching the nozzle. Apply the foam carefully, holding the can upside down and inserting the nozzle into the region that needs to be filled. Keep in mind that it will more than double in size once it's applied.

3. Moisten The Foam

Spray the foam with water right away after applying it. If you choose to apply more than one layer, spray water between each layer in order to help the foam adhere. Depending on the manufacturer's directions, the foam will typically take some time to fully cure.

4. Cut Off Any Excess Foam

In getting rid of extra spray foam, you should wait until it has dried. If you attempt to try anything while the foam is drying, it will peel and leave a mess. Use a hacksaw to carefully cut off any extra foam.

Click here to see this mini hacksaw on Amazon.

5. Sand The Area

To smooth out the foam's surface, use sandpaper. You can now plaster or paint over the expanding foam.

Click here to see this variety of sandpapers on Amazon.

A video demonstration of how to use expanding foam is shown below.

What Are The Types Of Expanding Foam?

Here are the three most common varieties of expanding foam or spray foam:

Low Density

Spray foam with a low density is effective at keeping out air but not moisture. That is because it is a low-density, sponge-like foam that expands considerably. The foam is kept very light by the bubbles that are inside of it. It does a wonderful job of filling open areas and can act as an insulator because it is so light and airy.

Medium Density

The medium-density foam works well as a vapor barrier. As it is dense but extends quite a bit, it is a fantastic choice if you're unsure about what to choose. It is the kind of spray foam that's most frequently used in crawl spaces.

Spray foam with a medium density resists tearing and cracking, since it is neither too dense nor excessively spongey. It's popular because it is almost always a sure thing. You can't go wrong with it.

High Density

Spray foam with a high density is robust and dense. It is excellent for sealing roofs so that air and water cannot enter. Additionally, it is waterproof and works well outdoors, unlike spray foams with lower densities.

It can also serve as a thin layer of insulation rather than a dense one. When cured, this form of expanding foam is the heaviest, weighing pounds per cubic foot as opposed to two pounds or less for lighter varieties.

Expanding Foam: Dos And Don’ts

Before you buy or start using expanding foam, read on to learn some important dos and don'ts:

Dos

Check The Expiration Date

Before using expanding spray foam, you need to check its expiration date. Expanding foam works best when it is new. That is why most merchants will take outdated cans off their shelves. If you see that your expanding foam container is past its expiration date, throw it away.

Noisy Water Pipes Solution

The purpose of expanding foam is not limited to preventing heat transfer and draught. It also works perfectly to silence water hammers or noisy pipes.

Water hammering happens when a valve turns off briskly. This results in a pressure surge that shakes the pipe, which can occasionally be strong enough to cause banging and rattling.

Keep A Solvent Nearby When Applying

Applying expanding foam carefully is essential in order to prevent getting the sticky foam on other things. Once it hardens, any excess must be removed by cutting, sawing, or sanding. If expanding foam accidentally gets somewhere it shouldn't be, remove it while it's still foamy with a solvent like WD-40 or acetone.

Click here to see this WD-40 on Amazon.

Protect Yourself

Expanding foam is thought to be harmless once it has dried. However, the gasses emitted during the application, known as isocyanates, might irritate the nasal passages and cause respiratory issues.

Additionally, wet foam can irritate the skin, resulting in rashes and redness. People who have allergies, asthma, or skin disorders frequently experience worse symptoms. So it is appropriate to use protective gear such as a mask and gloves for safety purposes.

Click here to see these heavy-duty gloves on Amazon.

Don’ts

Use Around The Outlet

It can be challenging to modify the wiring in an outlet because the foam spreads out quickly and might enclose the wires entering the conjunction box. It would be preferable to surround the box with a small amount of fiberglass batt insulation.

Maximum Application On The Window

One of the main applications for expanding foam is to seal gaps around windows. However, if the incorrect kind of foam is used, it could be difficult for the window to function.

You should use low-expansion foam for the window because it can only expand up to 30 times its liquid content size, as opposed to 300 times for high-expansion foam. This rapid pressure buildup can make it challenging to open and close windows.

Using Near Open Flame or A Spark

Although some varieties of expanding foam, like Great Stuff Fireblock, are made to stop the spread of flames, there is still a fire risk when the product is actually being used.

Click here to see this Great Stuff fire block on Amazon.

Utilizing the product in a confined area increases the chance of compressed gas accumulation and the ignition of a spark. This is because extremely explosive gas is used to drive the liquid polyurethane components out of the can.

When using expanding foam, extinguish pilot lights and refrain from smoking. Candles should be put out, and opening windows will promote airflow, which can aid in the gas's dispersion. Up until it is entirely dried, expanding foam is combustible.

Wrapping Things Up

The drying and curing of expanding foam will take time and always depend on several factors such as the product’s composition, the quantity of foam applied, temperature, and the humidity of the area.

If you want the expanding foam to dry faster, you need to first dampen (but not wet) the area where you are going to apply it. You should mist it with water while applying it because expanding foam requires moisture to expand and cure.

Before leaving, check out the related posts below.

Does Foam Insulation Attract Termites?

Spray Foam Temperature Settings