If you're wondering how much concrete is needed to fill a cinder block. You've found the right post to answer your question. Whether you're just looking for information or want to make the correct purchase. Continue reading because we've researched everything you need to know to calculate the amount of materials required.

The concrete volumes necessary to fill voids inside a Concrete Masonry Unit (CMU) or standard cinder block are as follows:

- 6" CMU, (6x8x16) = 356.96 in3

- 8" CMU, (8x8x16) = 473.82 in3

- 10" CMU, (10x8x16) = 645.14 in3

- 12" CMU, (12x8x16) = 748.08 in3

Read on as we elaborate more on how we come up with the total concrete filling inside a cinder block. We will also calculate how many cinder blocks you will be needing, the cost of each block and the factors that influence the price of a cinder block, and more.

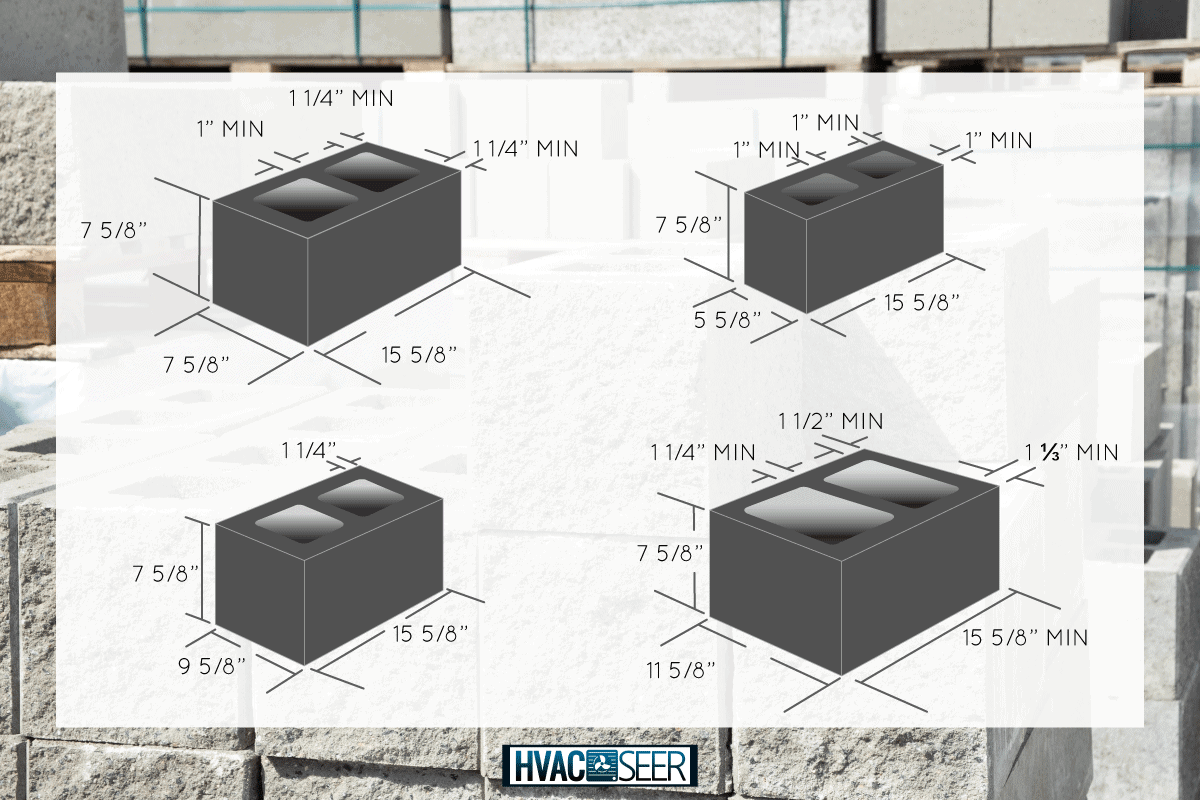

Cinder Block Dimensions

Cinder blocks are a type of concrete masonry block made from cinder, hence the name. When viewed from above, these blocks resemble the number '8' and are an efficient way to construct construction blocks. The aggregate in these blocks is cinder, which is paired with cement and sand. Because they are hollow, cinder blocks make the most use of their structural material.

Cinder blocks come in a variety of sizes and are distinguished by their depth, which is defined as the wall's thickness. It's also available in half-size, which saves time on the construction site by reducing the need to cut cinder blocks.

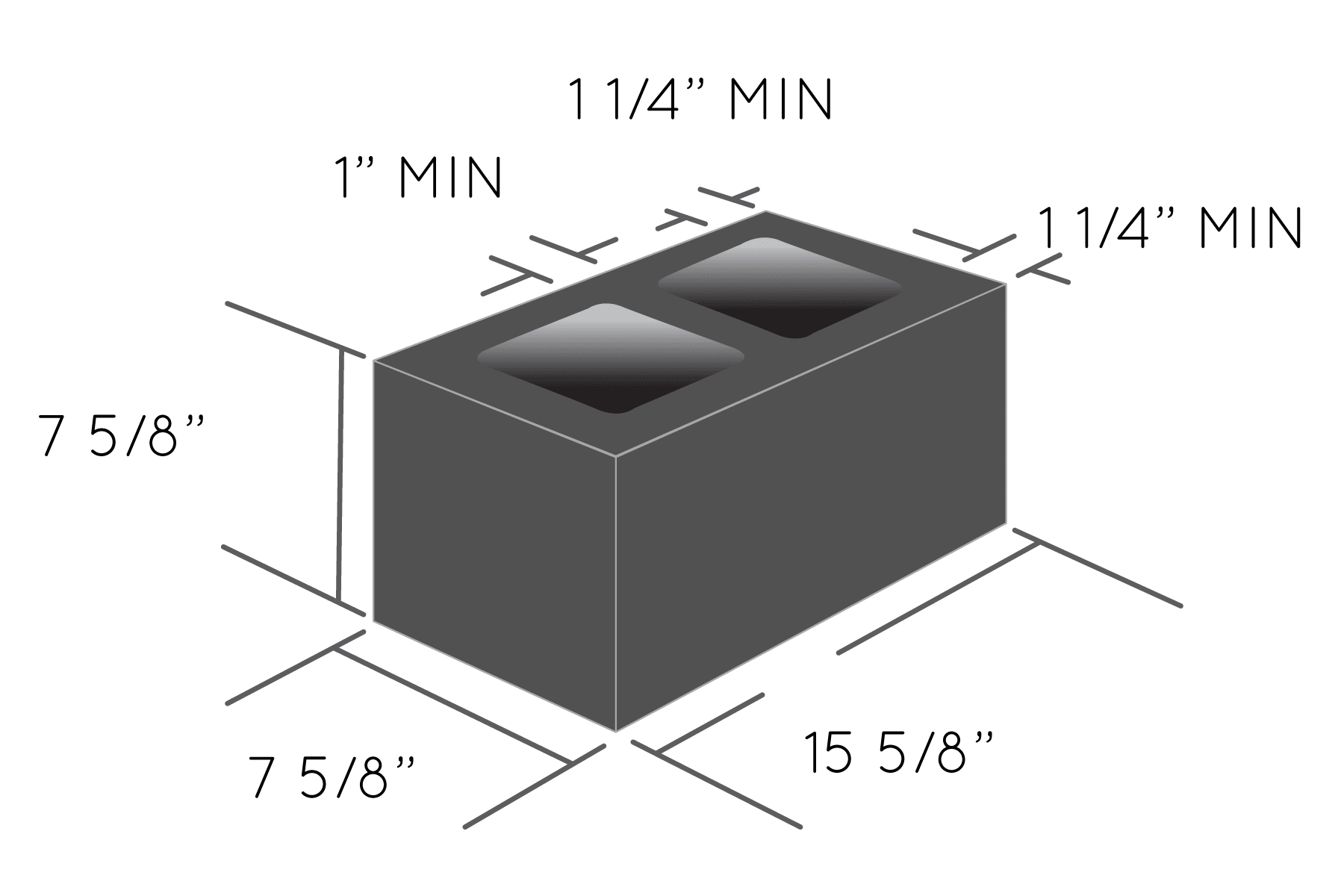

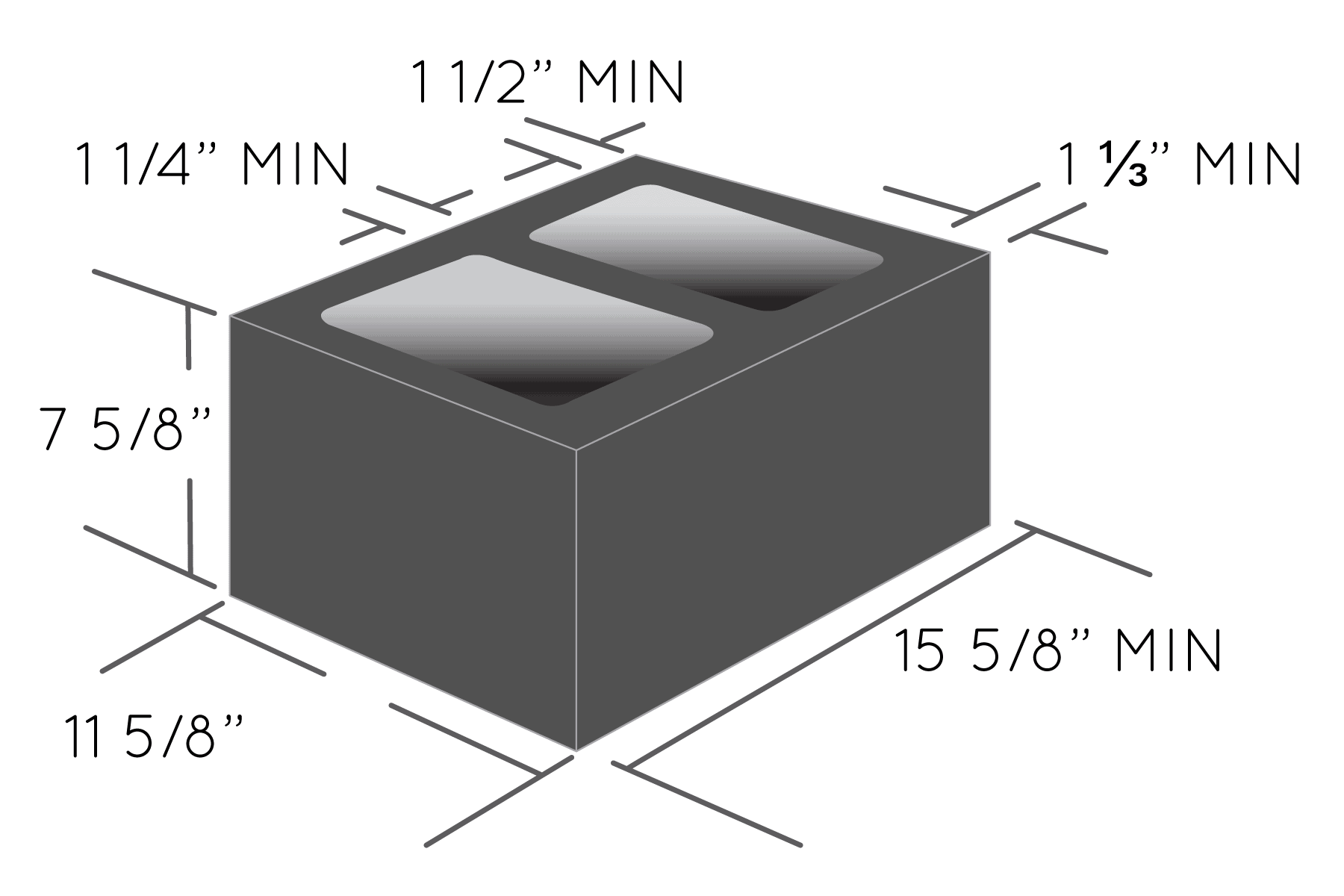

In the United States, the most common dimension is an 8" CMU, which is 8" wide, 8" high, and 16" long (8x8x16). However, their true size is 7 ⅝" wide, 7 ⅝" high, and 15 ⅝" long, with a 3/8-inch allowance for the mortar joints, as shown below:

Cinder blocks typically have two large holes separated by a 1-inch divider. The indented ends are 1-1/4-inch deep and vary in width from less than an inch to several inches.

When fabricating cinder blocks, they must adhere to American Society for Testing and Materials (ASTM) standards. Aside from the commonly used 8" CMU (8x8x16), the following are the other sizes based on ASTM standards with images represented from the RCP block:

Note: Their actual size measures 3/8-inch shorter to accommodate mortar joints and is represented in width (inches) x height (inches) x length (inches).

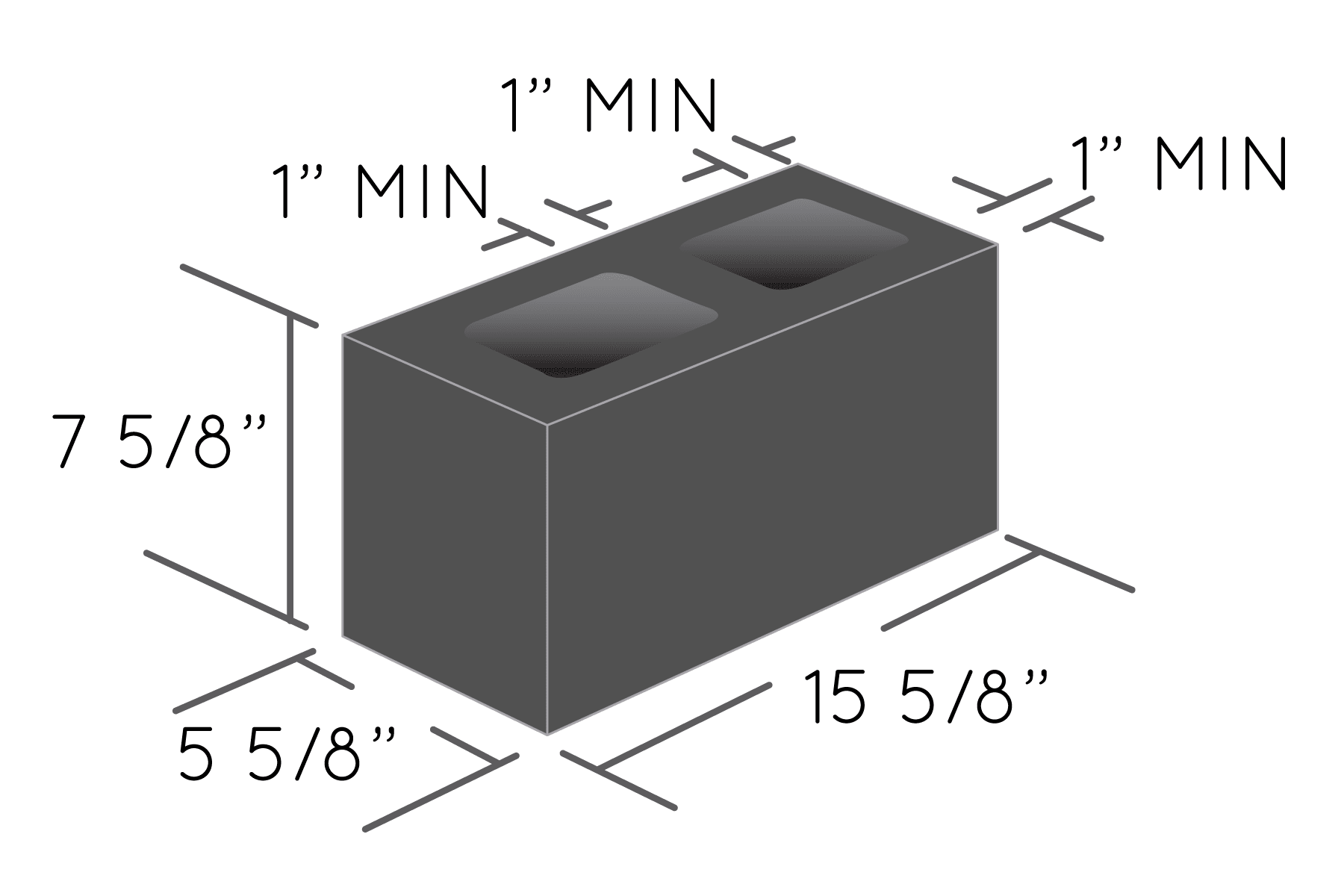

6" CMU, (6x8x16):

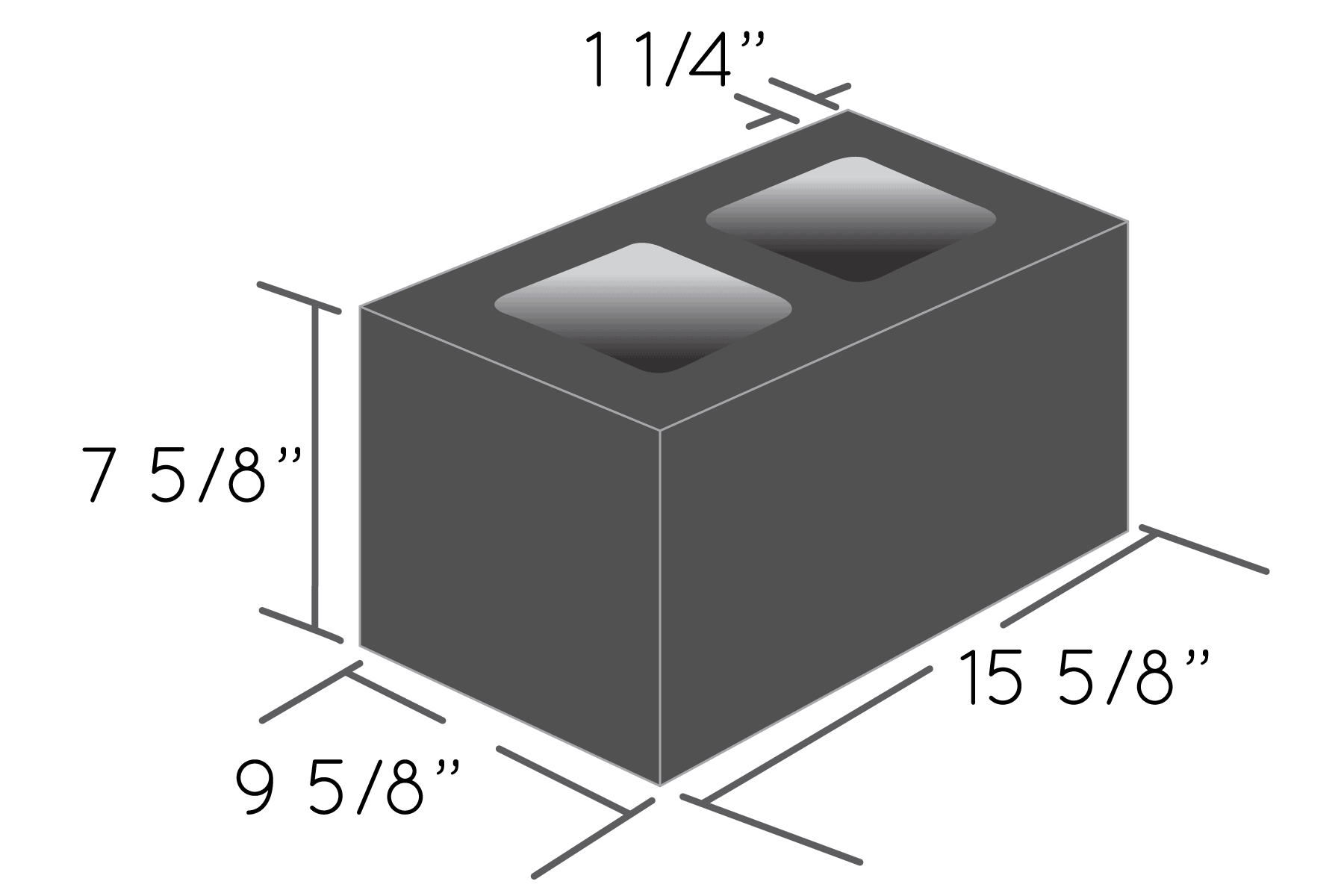

10" CMU, (10x8x16):

12" CMU, (12x8x16):

Do you fill cinder blocks with concrete?

Because of the structure of cinder blocks, constructing walls with them results in void spaces within the walls. To make a cinder block wall as strong as possible, these void spaces should be filled with concrete or mortar.

Steel reinforcing bars or rebars will strengthen the cinder block wall even more, especially against cracking, as they do in most concrete structures. Filling in the cores where the rebars will be installed ensures that the cinder block and rebars are properly bonded, resulting in a column-like structure running the length of the wall.

How much concrete to fill a cinder block?

Considering that the concrete blocks come in a variety of sizes, the amount of concrete required to fill each one will vary too. Cinder blocks are made by pouring concrete into molds to form two concrete planes or shells that are connected by concrete webs.

There are void spaces called cores or cells between the webs, which must be filled with concrete. To calculate the concrete filling of each block, you need to determine the volume of the core by determining the length, width, and height (LxWxH) and then multiply it by the number of cores that each block has.

Manual calculations are shown below:

6" CMU, (6x8x16)

- Width: (5 ⅝" - 1" - 1") = 3 ⅝"

- Height: 7 ⅝"

- Length: (15 ⅝" - 1" - 1" - 1") ÷ 2 = 6 5/16"

- Core's Volume: (3 ⅝") x (7 ⅝") x (6 5/16") = 174.48 cubic inches

- Total Concrete Volume per Block: 178.48 in3 x 2 holes = 356.96 in3

8" CMU, (8x8x16)

- Width: (7 ⅝" - 1 ¼" - 1 ¼") = 5 ⅛"

- Height: 7 ⅝"

- Length: (15 ⅝" - 1 ¼" - 1" - 1 ¼") ÷ 2 = 6 1/16"

- Core's Volume: (5 ⅛") x (7 ⅝") x (6 1/16") = 236.91 cubic inches

- Total Concrete Volume per Block: 236.91 in3 x 2 holes = 473.82 in3

10" CMU, (10x8x16)

- Width: (9 ⅝" - 1 ¼" -1 ¼") = 7 ⅛"

- Height: 7 ⅝"

- Length: (15 ⅝" - 1 ¼" - 1 ¼" - 1 ¼") ÷ 2 = 5 15/16"

- Core's Volume: (7 ⅛") x (7 ⅝") x (5 15/16") = 322.57 cubic inches

- Total Concrete Volume per Block: 322.57 in3 x 2 holes = 645.14 in3

12" CMU, (12x8x16)

- Width: (11 ⅝" - 1 ½" - 1 ½") = 8 ⅝"

- Height: 7 ⅝"

- Length: (15 ⅝" - 1 ½" - 1 ¼" - 1 ½") ÷ 2 = 5 11/16"

- Core's Volume: (8 ⅝") x (7 ⅝") x (5 11/16") = 374.04 cubic inches

- Total Concrete Volume per Block: 748.08 in3

You can calculate how much concrete is required to completely fill a structure by multiplying the total volume of each block's cores by the total number of blocks needed to build the structure.

How many cinder blocks do I need?

The first step in determining the number of blocks required is to determine the size of the structure where you will install the cinder blocks. To do so, multiply the height and width of the structure or wall. After that, divide the total structure area by the area of the single cinder block.

For example, assuming your wall will be 15 feet tall and 30 feet long. It will cover 450 square feet (15'x30'), converting to inches which is 64,800 square inches. A single 16" by 8" block has a surface area of 128 square inches, so you'll need 507 concrete blocks (64,000 in2 ÷ 128 in2).

How much does a cinder block cost?

A standard cinder block can cost anywhere from $1 to $5 per block. There are several factors to be considered in the price of cinder block on the market:

- The greater the size of the block, the higher the price.

- The cost of your cinder block is determined by where you live. To a large extent, the cost is determined by the availability of cinder blocks in your area.

- It's also worth thinking about the vendor you're buying from. Market conditions will cause a vendor to adjust the price. As a result, the actual price will be determined by the overall supply chain and market demand.

- Consider the block style as well. In various projects, various block styles are used. As a result, the money you spend is determined by the type you use.

What type of concrete is used for cinder blocks?

Choose type S of QUIKRETE® Mason Mix for cinder block construction. Forgiving to those who aren't masonry experts, the QUIKRETE® pre-blended mix remains useful for a long time without sacrificing the high bond strength that ensures project success.

Pay close attention to the package's printed instructions when preparing the mixture. The only ingredients are mortar mix and water; the key is to strike the right balance between the two. Use a mixing hoe to combine both ingredients in a mixing bin or wheelbarrow. Continue mixing until you have a consistency that can be troweled easily.

Advantages of Using Cinder Blocks

Cinder blocks provide numerous advantages. Some of them are listed below:

- Cinder blocks can withstand high temperatures. This improves the safety of your building by lowering the risk of fire.

- The structure is cooler than usual due to poor thermal conductivity.

- Simple to put together. Such materials allow for quick completion of projects. The time span isn't particularly long.

- You can choose from a variety of options. Cinder blocks can be used to create a variety of geometric designs for the project.

Advantages of Using Cinder Blocks

- It's expensive to maintain a cinder block. Repairing and maintaining cinder blocks has cost more money. As a result, the project's overall cost rises.

- Cinder blocks soak up water easily. This causes structural damage and reduces capacity.

- Noise isn't muffled by cinder blocks. The cinder blocks allow for a wide range of noises to pass through.

Difference Between Cinder Blocks and Concrete Blocks

Cinder blocks are made of glue and cinder. They are lighter in weight and cannot tolerate high pressure. Cinder blocks are usually used in smaller projects. They are no longer used in standard construction. For the past 50 years, they haven't been mass-produced. And also, cinder blocks must be repaired frequently. This raises construction costs and adds to the hassle.

Meanwhile, concrete blocks are made of concrete, steel, and wood. They are heavier in weight and able to tolerate higher pressures. Concrete blocks are commonly used in large construction. They are harder and stronger compared to cinder blocks. That’s why their use is widespread in the construction industry now. Also, concrete blocks are durable and require little maintenance.

Final Thoughts

Finding how much filling material you need for your cinder blocks depends on what size or type of blocks you have. The bigger the block, the more filling you needed. You only need to calculate the total volume of the cinder block's voids or holes, and you will get how much concrete you need to fill it. Hopefully, this can help you calculate the concrete you need for your cinder blocks construction.

Before you go, here are more articles you can enjoy:

R-Value Of A Cinder Block Wall

What’s The Best Insulation For Soundproofing Ceilings And Walls?