You may be wondering if you can add fiberglass insulation to your concrete walls. We asked insulation professionals this question to help you learn how to do it yourself.

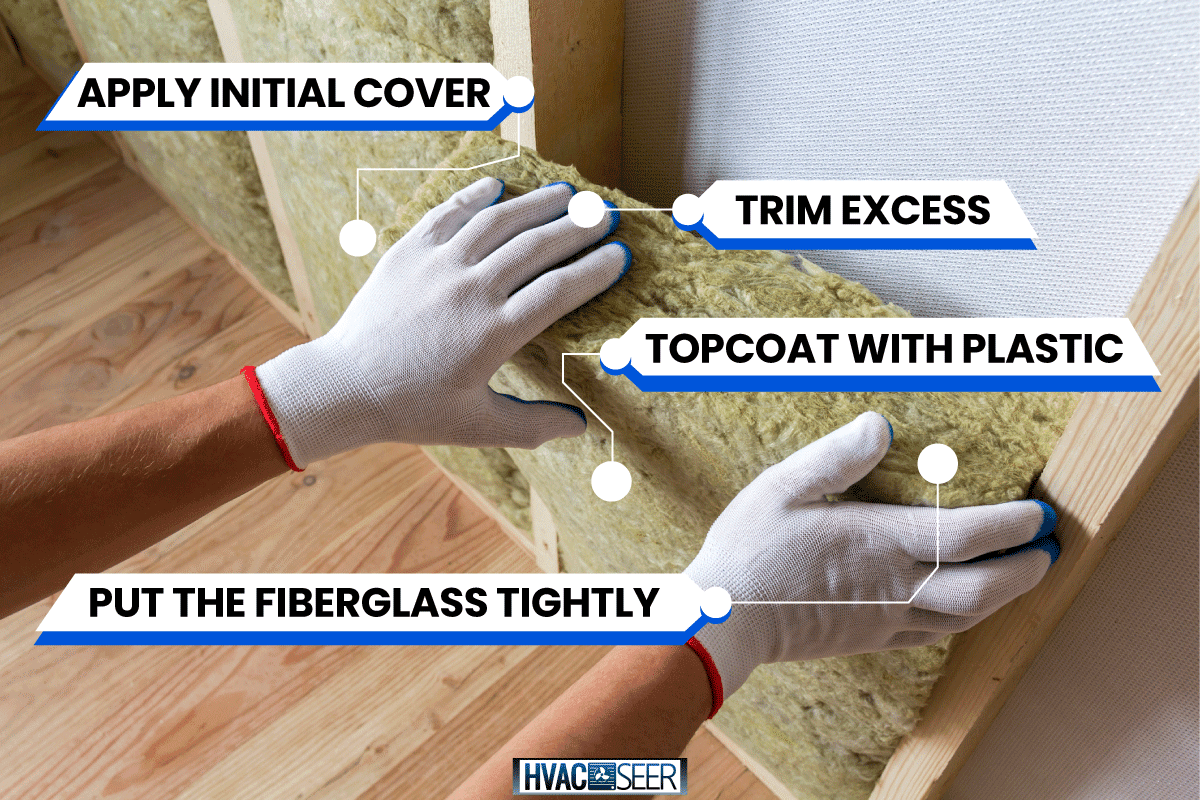

Installing fiberglass insulation batts to a concrete wall requires a proper, safe, and secure fit. Here is the step-by-step procedure:

- Apply initial cover.

- Put the fiberglass in the cavity tightly.

- Trim the excess.

- Topcoat with plastic.

- Secure it with staples.

In this post, we will guide you through the installation process and cover the strengths and weakness of fiberglass insulation. We will also discuss other essential aspects of attaching fiberglass insulation to concrete walls. To learn more, keep on reading.

How Do You Add Fiberglass Insulation To Concrete Wall?

Here are the simple yet effective steps for attaching fiberglass insulation to your concrete walls.

Things You Will Need

Prepare the items you will use in this project.

- Tape measure

- Utility knife or cutter

- Stapler

- Step ladder

- Fiberglass insulation

- Staple gun

Apply initial cover

To prevent moisture problems, use a foam spray between the fiberglass and concrete wall. This will aid in making the insulation last longer by combatting molds and mildew brought about by moisture.

Placing the fiberglass

Put the fiberglass in the wall cavity tightly yet carefully. Ensure there are no gaps.

Trim the excess

Using a utility knife, trim the excess insulation slightly beyond the baseboard. Then compress it gently. If there is wiring, cut an inch on the back portion of the fiberglass along the wires before you install the fiberglass. You should split the batt into cross-sections when big pipes are present. For power outlets, cut the area based on the shape of the outlet.

Topcoat

Use a topcoat of polyethylene for extra protection.

Securing with staples

Secure the material using a heavy-duty staple gun with 1/4 inch staples along the wall studs.

Click here to see this staple gun on Amazon.

Safety Tips

Before we proceed, practice these measures to keep yourself safe against the dangers of fiberglass exposure:

- Wear personal protective equipment (PPE) such as gloves, masks, goggles, closed shoes, and overalls.

- Open doors and windows to maintain good airflow.

- Wash your hands properly before touching your face.

- Avoid storing food or drinks in your work area.

- Wet-wash the floor, other surfaces, and dirty PPE to wipe out the fiberglass dust.

- Invest in home appliances with HEPA filters like purifiers and vacuums.

- Discard excess or old fiberglass properly.

For more insights, read this post: Can You Mix Fiberglass And Cellulose Insulation?

Can You Put Fiberglass Insulation On The Walls?

Since fiberglass insulation is not moisture-resistant, experts do not recommend placing it directly on concrete walls. You can either add vapor barriers or other insulators in addition to the fiberglass.

Can You Cover Fiberglass Insulation With Plastic?

Fiberglass insulation needs to be covered with plastic. The plastic commonly used to cover fiberglass insulation is called a 6-mil polyethylene sheet. It serves as a vapor barrier but allows the insulator to breathe.

Click here to see this clear plastic sheeting on Amazon.

Does Fiberglass Insulation Need To Be Replaced?

Fiberglass insulation is an investment that can increase your comfort and last for up to ten decades. But it may begin to show some wear and tear due to moisture exposure as early as 15-20 years. That is why it is recommended that you replace or repair it when there is noticeable damage.

How Effective Is Fiberglass Insulation?

Whether batts, loose-fill or rigid fibrous, fiberglass is a durable and permeable insulation. It is a plastic made with glass fibers. There are three varieties of insulation facing for moisture control: unfaced, FSK facing, and kraft-facing. The faced fiberglass inhibits water vapor and condensation.

Click here to see this kraft-faced insulation roll on Amazon.

Fiberglass insulation can provide roughly 50% savings on your electric bills. However, based on the Insulation Institute's compression guide, the performance of batt insulation increases when compressed into the wall cavities, but the overall R-value decreases.

As a result, along with additional sealing and vapor barriers, proper installation is key to the effectiveness of fiberglass insulation.

What Is The Best Insulation For Walls?

The best wall insulator depends on the location of where you will install it. Some areas require a higher R-value, while others need the bare minimum.

Usually, the walls range from R-13 to R-21. The ideal value for attics is between R-30 and R-50. Similarly, several floors have R-13 to R-30, whereas crawl spaces require R-13 to R-30.

What Are The Alternatives To Fiberglass Insulation?

Despite the advantages mentioned, other types of insulation can fill in the areas where fiberglass falls short. We've prepared a list of the common alternatives for fiberglass insulation.

Rigid Foam Board Insulation

This is a higher-cost insulator with a lower R-value per inch (R-2) than fiberglass. It is also moisture resistant yet highly flammable. Thus, you will need a thermal barrier like gypsum boards beneath this insulation to prevent corrosion.

Foam boards are available in small pieces. With these, you can tailor their shape and cover a few wall sections, particularly window or door edges.

Click here to see this insulation foam board on Amazon.

Closed Cell Spray Insulation

Another type of insulation is closed cell spray foam. This type of insulation has a greater thermal performance of R-7 per inch. Along with the moisture and vapor barrier, its system is high-performing foam insulation.

It is sustainable and energy efficient when properly installed, especially during extreme temperatures. You can also pair it with fiberglass.

Click here to see this closed cell spray bundle on Amazon.

Mineral Wool

Unlike fiberglass, mineral or stone wool has a higher thermal performance with R-15 at 3.5 inches. It is also heavier and more rigid when installed. In addition to these properties, it has qualities similar to fiberglass: it is fire-resistant and non-flammable.

Aside from insulation, it goes well with acoustic panels for soundproofing. It is also perfect for exterior walls, crawlspaces, and basements.

Click here to see this mineral wool board on Amazon.

Cellulose Insulation

Loose-fill cellulose insulation is made from cotton, sawdust, or paper, making it combustible. Experts treat it with chemicals to diminish this property. It is an affordable option to block airflow. It is also suitable for newly constructed walls, attic flooring, and isolated areas of the house.

Click here to see this natural cotton insulation on Amazon.

Final Thoughts

Fiberglass insulation is a popular choice for home builders. However, you must install it correctly and safely to fully enjoy its benefits.

Thanks for reading! If you enjoyed this post, here are similar articles you may like:

How To Clean Up Fiberglass Insulation?