There are many kinds of tape on the market—sometimes it's hard to choose one. What if you narrowed it down between HVAC and duct tape? There's no better way to pick than to compare them. If you want to see the differences between HVAC and duct tape, let's compare!

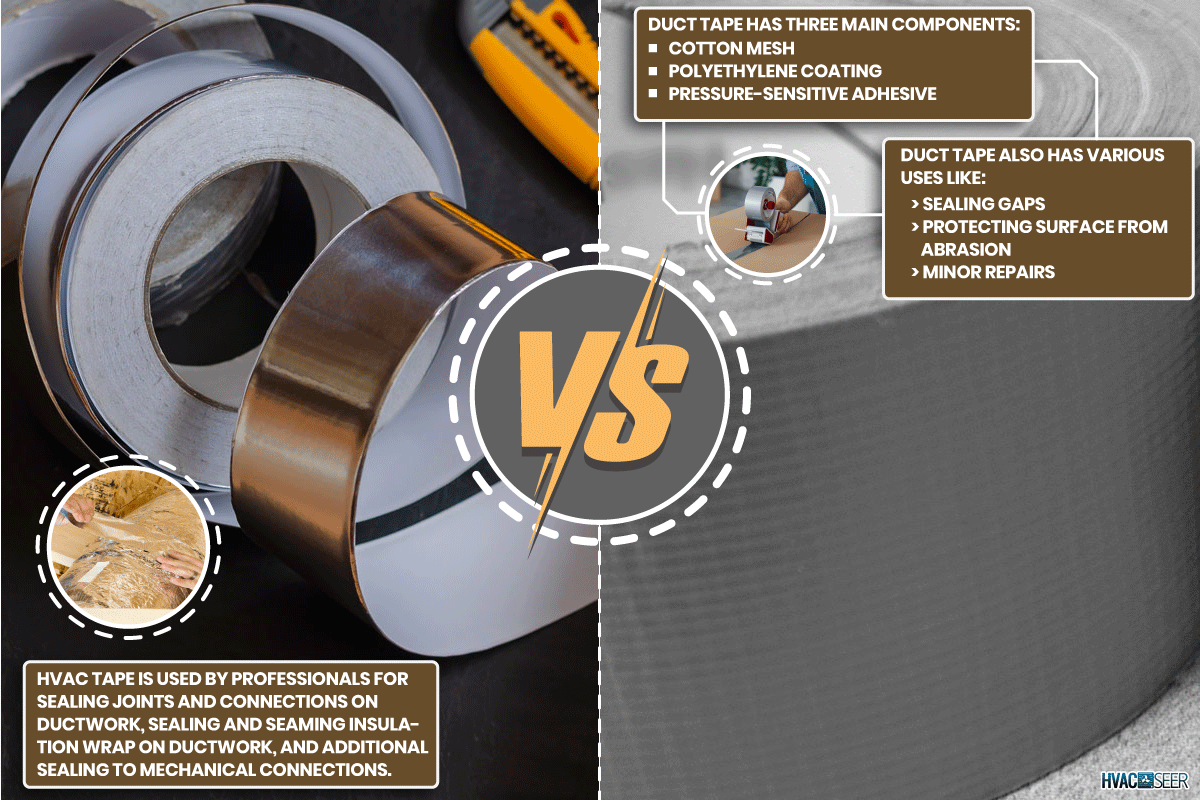

Duct tape has three main components: a cotton mesh, polyethylene coating, and a pressure-sensitive adhesive. It has various uses like sealing gaps, protecting surfaces from abrasion, and minor repairs.

HVAC tape has various components. Professionals use it for sealing joints and connections on ductwork, sealing and seaming insulation wrap on ductwork, and additional sealing to mechanical connections.

Duct and HVAC tape have different purposes—that much is clear. However, why do their materials differ? In addition, can you use one in place of the other? These are some of the concerns we'll address. To learn more on this topic, keep reading.

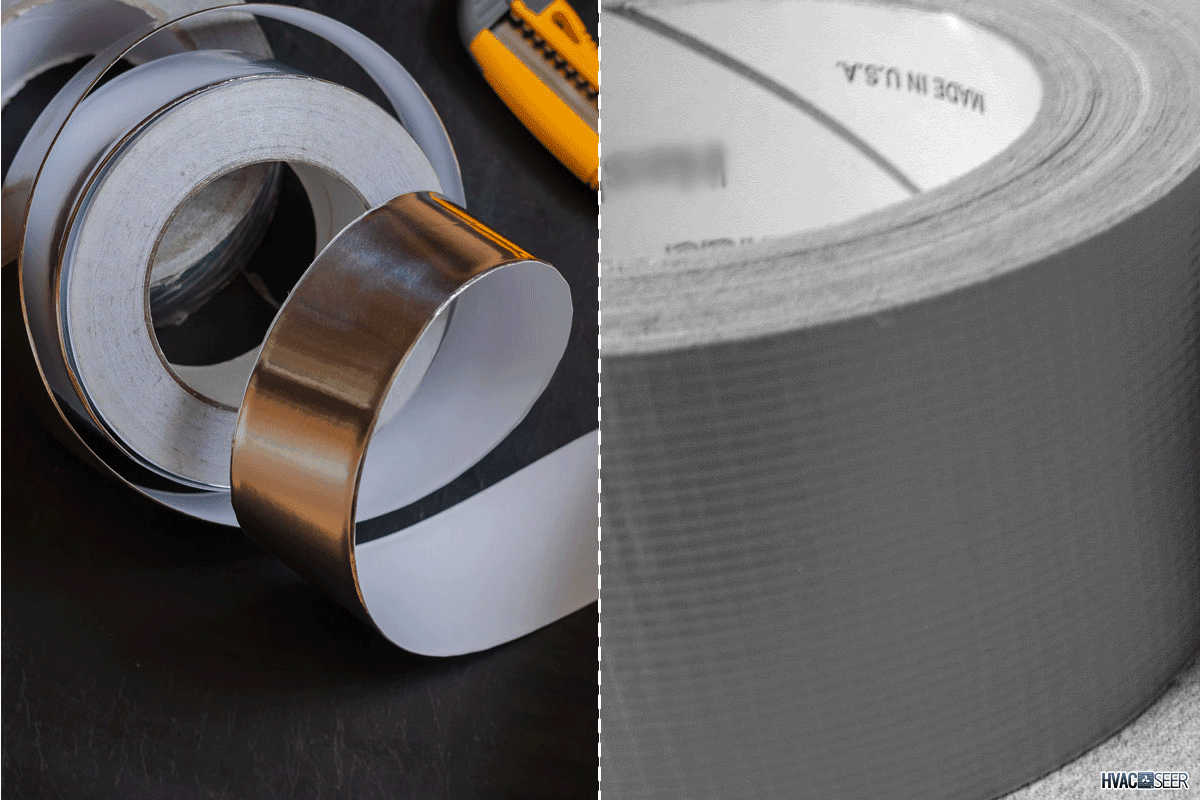

HVAC Tape Vs. Duct Tape

It won't take long to notice the difference between the two tapes; most people will be familiar with duct tape. It's a silvery gray tape with a good reputation.

Chances are that you've already witnessed how well it can perform. Duct tape is water resistant, strong, relatively easy to tear when you need to, and flexible. It's versatile enough that everyone resorts to using it when they can.

However, there are some jobs it can't do. More specifically, it won't work well for HVAC-related repairs. For this reason, we have a separate category of tape. Let's look at how different HVAC tape is from duct tape.

What Is HVAC Tape?

HVAC tape differs from duct tape in many ways. If we look at the materials it's comprised of, we'll find that HVAC tape has many. The type you'll need depends on what the job requires.

The three types of backing it can have are aluminum foil, film, or composite. A tape's backing serves to protect the adhesive on the other side. However, that's not its sole purpose.

Now let's look at what it uses to bond to various materials.

Adhesives

If you want the tape to last a long while, it needs to form a permanent and secure bond; the three adhesives HVAC tape uses satisfies this requirement. You'll find it nearly impossible to remove this tape once you apply it.

HVAC work requires the utmost protection and stability—two things duct tape can't provide. For this reason, HVAC tape can use one of three strong adhesives; the three common ones for this tape are acrylic, butyl, or rubber based.

Conformability

HVAC work also requires versatility. The surfaces that will need the tape will have nooks and crannies. For this reason, the job requires something that can conform to irregular or non-smooth surfaces.

Once again, HVAC tape meets this requirement. It's not as stiff as duct tape. Therefore, it can fit into crevices where a good seal is essential.

Permeability

As the name implies, HVAC tape is for HVAC usage, but what does HVAC usage involve? It involves sealing air leaks and preventing contaminants from entering your HVAC system.

HVAC tape accomplishes this job with flying colors. Some are non-permeable, while others allow some air to pass. As mentioned, it depends on what the job requires.

Nevertheless, you want to prevent air leaks when possible. Otherwise, your home will be less energy efficient.

Strength

HVAC systems are in place to maintain adequate temperatures in your home. Without them, it would be too hot or cold. Since the air going through your ductwork will vary in temperature, you want tape that can hold up in various conditions.

Yet again, HVAC tape meets this requirement.

UL Rating

HVAC tape also carries two types of UL ratings; it may be UL 181A-P or UL 181B-FX listed. These ratings indicate their usage.

UL 181A-P

If the tape is UL 181A-P listed, you can use it to seam, seal, and join rigid fiberglass duct board; seam, seal, and join flexible air ducts; seam, seal, and join sheet metal.

UL 181A-P listed HVAC tape will have aluminum or aluminum foil backing. In addition, it will use an acrylic adhesive to bond to materials.

Since the acrylic adhesive is aggressive, the tape will have a release liner that you need to remove before applying. An HVAC tape with this rating will be safe enough to withstand the temperature fluctuations of HVAC systems.

UL 181B-FX

HVAC tapes with a UL 181B-FX rating are more use-specific. You can only use it for class 1 flex duct. Of course, this tape is for seaming, sealing, and joining HVAC materials.

UL 181B-FX listed HVAC tapes will vary in the backing they use. It can use foil, film, or cloth.

If you want to go over a brief overview of HVAC tapes, here's a video to help:

What Is Duct Tape?

Duct tape doesn't need an introduction. However, it helps to know what it's comprised of. If you didn't know, duct tape today is comprised of nearly the same materials it used in the past.

It's made up of three basic components: a cotton mesh, a plastic coating, and a pressure-sensitive adhesive. The cotton mesh gives it tensile strength and a clean tear.

Of course, cotton isn't a material that can withstand all types of damage. So, a plastic coating is a must. It protects the cotton mesh from liquid and other types of damage.

In terms of adhesive, it uses a rubber-based one. This is why it can be aggressively sticky.

Types

The surprising part about duct tape is that there are variations of it. Most would purchase general-purpose duct tape, but there's also a professional-grade one.

General-purpose duct tape doesn't have a UL listing. For this reason, you should avoid using it for HVAC purposes. However, you can use it for anything else. Use it for sealing, patching holes, packing boxes, repairs, etc.

As long as the conditions aren't too extreme, it should perform well. If you must use duct tape for HVAC, look for professional-grade duct tape.

Professional-grade duct tape will be UL 181B-FX listed; this means you can use it for sealing class 1 flex ducts. In addition, it can work for sheet metal and duct repairs.

It's impossible to confuse the two. Professional-grade duct tape will make its use clear in the packaging.

Click here to see this duct tape on Amazon.

Can I Use Duct Tape on Air Ducts?

Now we can get into the specifics. What happens if you use duct tape in place of HVAC tape? There are two ways this can end. If you use the correct type of duct tape, it will last as long as it can.

Otherwise, using the wrong duct tape will end in you having to make more repairs. Of course, it fails because it can't handle the temperature fluctuations in the ductwork. More precisely, it's the adhesive that can't tolerate it.

The temperature changes in the ductwork will cause the tape to flag and fall off. As a result, you will have to pay more for heating and cooling bills because of the energy loss from air leaks.

Professional-grade duct tape is better for HVAC purposes. However, it's use-specific—meaning you can only use it for class 1 flexible air ducts. UL 181A-P HVAC tape is better for everything else.

Is HVAC Tape Permanent?

Adhesives play a large part in a tape's performance; you want it to last. With the information above, we know that HVAC tapes use aggressive adhesives. It raises the question—how aggressive are they? Does it form a permanent bond with the surface?

Yes, they do. As mentioned, HVAC tapes often use butyl- or acrylic-based adhesives. The tapes that use these adhesives will always come with a release liner.

Of the two, an acrylic adhesive is the one that can perform the best. It has a much higher application temperature range. Acrylic adhesives can withstand temperatures between -30-300 degrees Fahrenheit.

Butyl-based adhesives can withstand temperatures between 35-110 degrees Fahrenheit. Of course, this doesn't mean you should use HVAC tapes that use acrylic adhesives for everything.

Each tape has a specific usage.

In Closing

There's a lot that goes on with tapes. While they might all look the same, their performances aren't. Some tapes—HVAC tapes specifically—are more secure. So, do you have enough information to make a decision? We hope so!

Before you go, do you need to compare sealants? We have a post putting Rectorseal and Teflon tape head-to-head. For more information, check out:

Rectorseal Vs Teflon Tape: Which Thread Sealant To Use?

Here are other topics that might interest you: