Installing foam board insulation on concrete can provide numerous benefits to the property. But now you’re wondering about the correct steps to complete this task. We’re curious, too! So we researched this concern for your convenience, and here’s what we found.

First, prepare for the upcoming foam board insulation installation task. Make sure to take preventive measures and wear protective gear. Then, buy all the items needed for the job to reduce unwanted travel costs from multiple trips to the store. Once prepared, follow these steps:

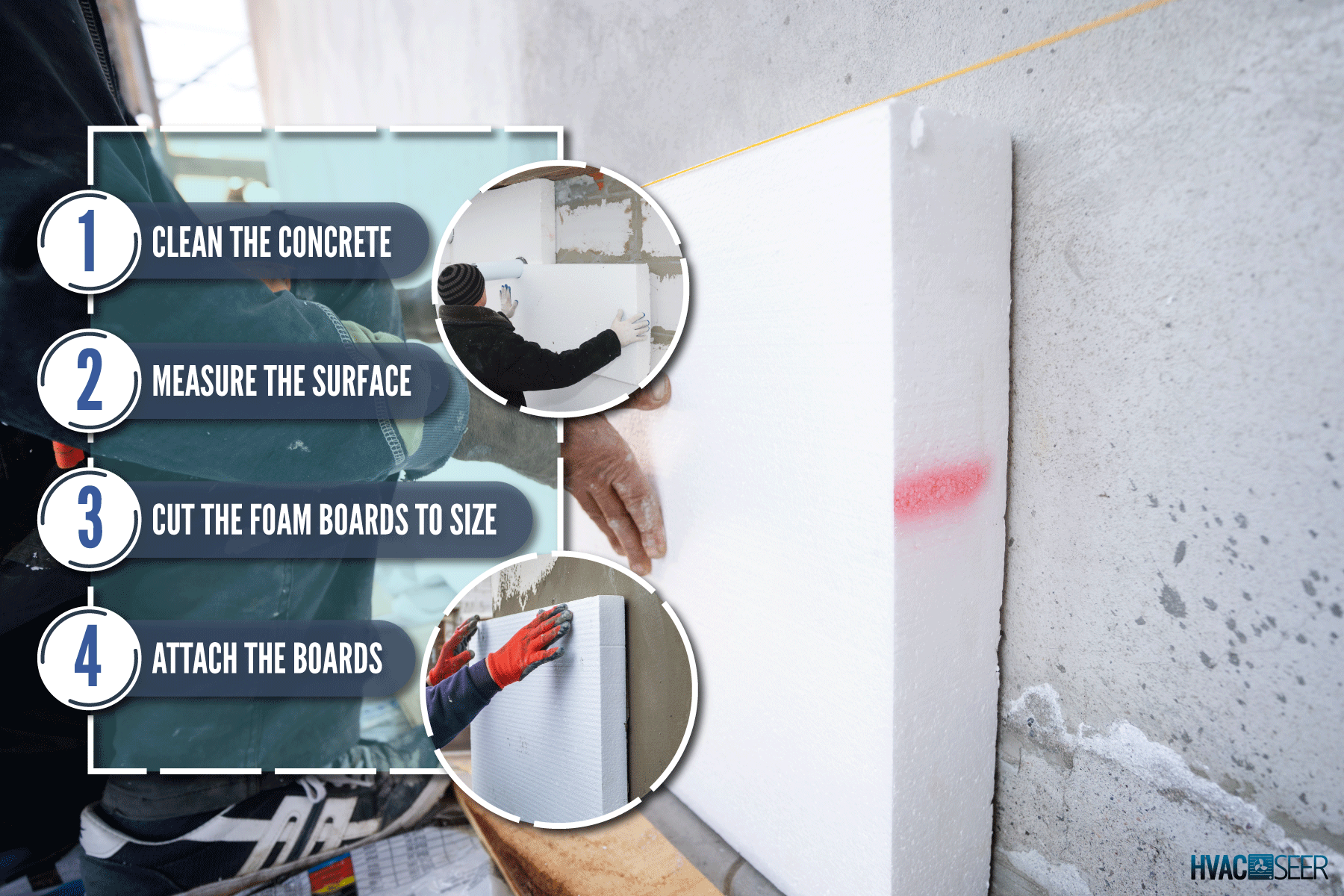

- Clean the concrete

- Measure the surface

- Cut the foam boards to size

- Attach the boards

You should continue reading as we tackle the details of this installation project. That way, you can reduce the risks of costly mistakes and prevent accidents and injuries that might otherwise happen.

Can You Install Foam Board Insulation On Concrete Directly?

It depends on the foam board you’re using. Concrete, particularly if unsealed, is porous. That means that you need a non-porous insulation board to cover the small holes efficiently.

Generally, many foam board insulation products have non-porous structures, making them water- and mold-resistant. On the other hand, expanded polystyrene boards (EPS) usually have air bubbles to help enhance air circulation. But EPS may also capture more moisture from the adjacent concrete and its surroundings, leading to issues like mold growth.

It’s still ideal to place something in between the concrete surface and the foam board insulation to enhance the thermal-resisting properties of the setup. One example is installing a vapor barrier between those two materials. However, check your property’s insulation needs first before adding that extra layer.

Read our post on the different foam board insulation available to gain additional insight into these options.

DIY Instructions To Install Foam Board Insulation On Concrete

Take note that proper preparation is essential in installing insulation. Taking preventive measures not only improves the task’s success rate, but preparing for the job can also reduce safety risks.

Here are some ways to prepare for your upcoming foam board insulation task:

- Wear proper clothing. Avoid loose clothing but cover your skin with clothes to prevent direct contact with harmful substances.

- Equip yourself with protective gear. Wear equipment like a respirator, safety gloves, and safety goggles to safeguard your nose, mouth, hands, and eyes.

- Keep your workspace as clean and as tidy as possible. Don’t leave your tools on the floor as they might promote falls and other harmful events.

- Ventilate the area. Prevent dust and dirt buildup on the job site by installing exhaust fans or by keeping the windows open.

- Clean up afterward. Don’t forget to remove the equipment used for the installation from the installation location.

Once prepared, continue the project by gathering the necessary items.

Things You’ll Need

It can be a good idea to obtain all the things needed for this insulation installation project in one go. That way, you can reduce your trips to the store and avoid delays.

The items you’ll need for this operation are:

- Plastic sheets

- Soft-bristled brush

- Vacuum cleaner

- Concrete cleaner

- Cloth or rag

- All-purpose cleaner

- Garden hose

- Steel tape measure

- Utility knife

- Adhesive

- Foam board anchor

- Hammer drill

- Masonry bit

- Foam boards

After obtaining the equipment and materials needed for the foam board insulation installation, you can move forward with this task by following these steps:

Step-By-Step Guide

Step #1: Clean The Concrete

Dirt, dust, and debris on the concrete surface may prevent the foam board insulation from supplying the best thermal resistance it can provide. Here’s a quick overview to clean and prepare the concrete surface:

- Place plastic sheets on the floor to prevent spills and extensive cleanups.

- Use a soft-bristled brush to dust off the concrete surface.

- Suck up leftover dust and dirt with a vacuum cleaner.

- Mix your preferred concrete-cleaning solution in a bucket according to the manufacturer’s instructions.

- Dip a cloth or rag in the cleaning solution, then wipe it on the concrete surface.

- Dilute an all-purpose cleaning solution in another container.

- Scrub the concrete with the soapy solution. Rinse the surface with clean water afterward.

- Let the water dry before moving to the next step of the insulation installation process.

If the concrete surface has evidence of mold and mildew growth, you can get rid of those substances with an application of a diluted bleach solution.

You can also learn an alternate way of cleaning concrete surfaces by watching the video below:

Step #2: Measure The Surface

Measure the concrete surface with a steel tape measuring tool. Make sure that your measurements read from one end of the concrete to the other. You also need to take into account some obstructions that might be in the way, particularly if you’re measuring a surface with unique dimensions.

Once noted, remove about 1/4th-inch from the total measurement. Slightly cutting the foam board insulation provides you with sufficient allowance to install and move the material into position.

Step #3: Cut The Foam Boards To Size

Lay the foam board on a flat and level surface. Then, use your utility knife to cut the material based on your measurements.

Next, lay the board on the concrete surface to test if the cut is accurate. If not, make adjustments to the cut until you get the desired size.

Step #4: Attach The Boards

You can use an adhesive to secure the foam board insulation onto the concrete. This option can be ideal if you’re placing the board onto bare concrete. Take note that you have different adhesive options to choose from, such as construction adhesive, wood glue, hot glue, and super glue.

However, if you’re going to install foam board insulation on another material that’s above the concrete, it might be better to use a foam board anchor instead of an adhesive.

Before you install the foam board anchor, drill a hole at the center of the insulating material with a hammer drill. Use a masonry bit for this particular step so it can pierce through the concrete.

Then, place the foam board anchor into the hole. Repeatedly tap the anchor with your hammer until it creates sufficient pressure on the insulating material.

After you finish installing one board, repeat these steps for the other pieces in the insulation set for the entire concrete surface. Seal the gap between each board with duct tape afterward.

Note: If you're using an adhesive, ensure that it's safe to use with foam boards. If not, the harsh ingredients may deteriorate those materials, reducing their insulating properties.

Check out this foam board insulation on Amazon.

Watch the video below if you need a visual guide to this procedure:

At this point, you might be curious if you can paint foam board insulation. Check out our post on that topic to know the answer.

How Long Will Foam Board Insulation Last?

It should take 100 years or more before foam board insulation deteriorates. However, certain factors exist that may reduce a foam board insulation’s serviceable life. Some of these possible suspects are:

- Poor-quality construction and/or material

- Poor manufacturing practices applied

- Improper installation

- Exposure to harsh chemicals

When Should You Replace Foam Board Insulation?

It’s time to replace your property’s foam board insulation if you experience thermal anomalies in your home. Here are some signs to watch out for if you need to replace your old or worn insulation boards:

- Inconsistent indoor temperature

- A rise in the energy bill

- Allergy attacks became more frequent than before

- Pests started invading your home

- Apparent mold and mildew growth

How Do I Know What Insulation Is Right For Me?

Take note that foam board insulation is only one of the different selections to choose from the market. Your choice can depend on different factors like:

R-Value

R-value is the coefficient used to measure an insulation material's ability to stop the flow of heat entering and exiting the property. A higher R-value typically means better thermal resistance.

Foam boards usually have R-values that range from 3.6 to 8.0. On the other hand, spray foam insulation often has R-values ranging from 3.6 to 7. Remember to check your property’s location and its climate while you’re still choosing the best insulation for your home.

Location

As mentioned earlier, there’s a correlation between an insulation material’s R-value with your location. Some locations may only require about R-13 to insulate floors. But other places might need approximately R-30 to experience the ideal thermal resistance.

Final Thoughts

Remember, don’t be hasty in installing the foam board insulation onto your concrete surface. Take the time in following the steps outlined in this post. Be patient and keep a keen eye on possible mishaps so you can complete this task with as little room for mistakes as possible.