One of the most challenging vehicle problems to diagnose is strange sounds from under the hood. The good news is that you have options for locating the noise and making the necessary fixes. Unusual engine noises are typically the consequence of an AC compressor pulley that has failed or become stuck. We have researched to help you identify and solve this issue.

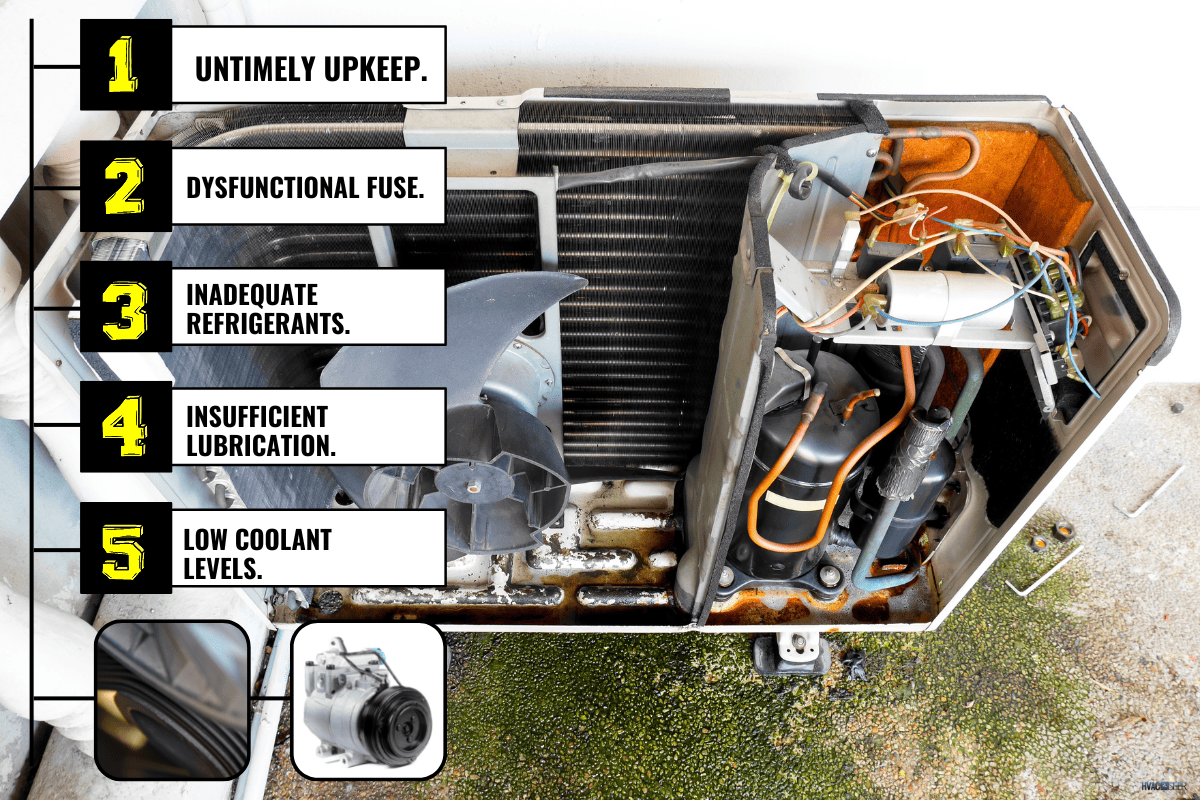

A faulty AC compressor pulley will have audible indicators from outside the vehicle. If you hear a grinding or whining noise from the engine when your car is idle, one of your pulleys likely needs to be replaced. You take the belt off to figure out which one it is. Here are the common problems why your AC compressor is not spinning:

- Untimely upkeep.

- Dysfunctional fuse.

- Inadequate refrigerants.

- Insufficient lubrication.

- Low coolant levels.

It's critical to understand the warning signals when an AC compressor pulley fails to safeguard the serpentine belt in your car. Unlike an impending compressor failure, you won't necessarily notice a failing pulley while the AC is operating. Keep reading to learn the causes of these AC problems and how to fix them.

What Stops The Pulley On An AC Compressor From Spinning?

The electronic clutch connected to the AC pulley allows it to spin freely while the air conditioner is not operating. The front pulley of the AC compressor turns the compressor and powers the engine. Even though the compressor is a crucial component of the AC system, the entire assembly will not function if any of these components are damaged. Here are some of the most frequent reasons for AC compressor pulley issues.

Untimely Upkeep

Car air conditioning compressors need regular maintenance. Use of the wrong or low-quality refrigerant, low coolant levels, and insufficient lubrication are a few causes why the compressor locks up. Before any problem becomes critical, you need to inspect your vehicle's AC.

Dysfunctional Fuse

When the AC compressor system wires receive too much voltage, they can blow a car's fuse. The fuse prevents overvoltage from damaging the car's components outlying the battery. A multimeter or other tools can be used to verify whether both ends are still electrically connected.

Check out this digital multimeter on Amazon.

Inadequate Refrigerants

Two AC lines, the high-pressure and low-pressure lines, within an AC compressor are crucial for maintaining the system's functionality. These two air conditioning lines are each connected to a pressure switch that opens when it detects a lack of refrigerants. The pressure switches will open if there is too much or insufficient refrigerant. This situation causes your AC compressor clutch to disengage.

Check out this freon leak detector on Amazon.

Insufficient Lubrication

An AC compressor needs lubrication to function. If the oil in your car's air conditioner compressor is low, it may heat up too quickly and degrade the load-bearing surfaces. Your air conditioner will stop working if the AC compressor clutch is worn out and cannot fully lock onto the pulley.

Check out this AC dye kit on Amazon.

Low Coolant Levels

The coolant temperature can rise, but not because of the elevated coolant temperature. Lack of airflow between the condenser and radiator might be the culprit in both procedures.

Check out this coolant leak repair on Amazon.

How To Check AC Compressor Pulley

Different vehicle models tend to have slightly different causes for these problems. Examine the issues with your AC compressor pulley by following the instructions listed below.

Track Down The Pulley And The AC Compressor

If you suspect the AC compressor and pulley in the engine are the culprits, locate them as soon as possible. Following the belt path can help you identify the air conditioner compressor pulley.

Check out this belt tensioner assembly on Amazon.

Drive Belt Removal

After removing the drive belt, manually spin the AC compressor pulley and inspect it. It should rotate if there's no belt strain on the pulley. There may be an issue if you hear any grinding, squeaking, or other unusual noises.

Check out this serpentine belt tool set on Amazon.

Examine The AC Compressor Pulley

The compressor rotates due to the pulley's connection. A locked bearing prevents it from spinning freely. If the pulley rotates with reluctance, this could be another crucial symptom that the joint is binding up.

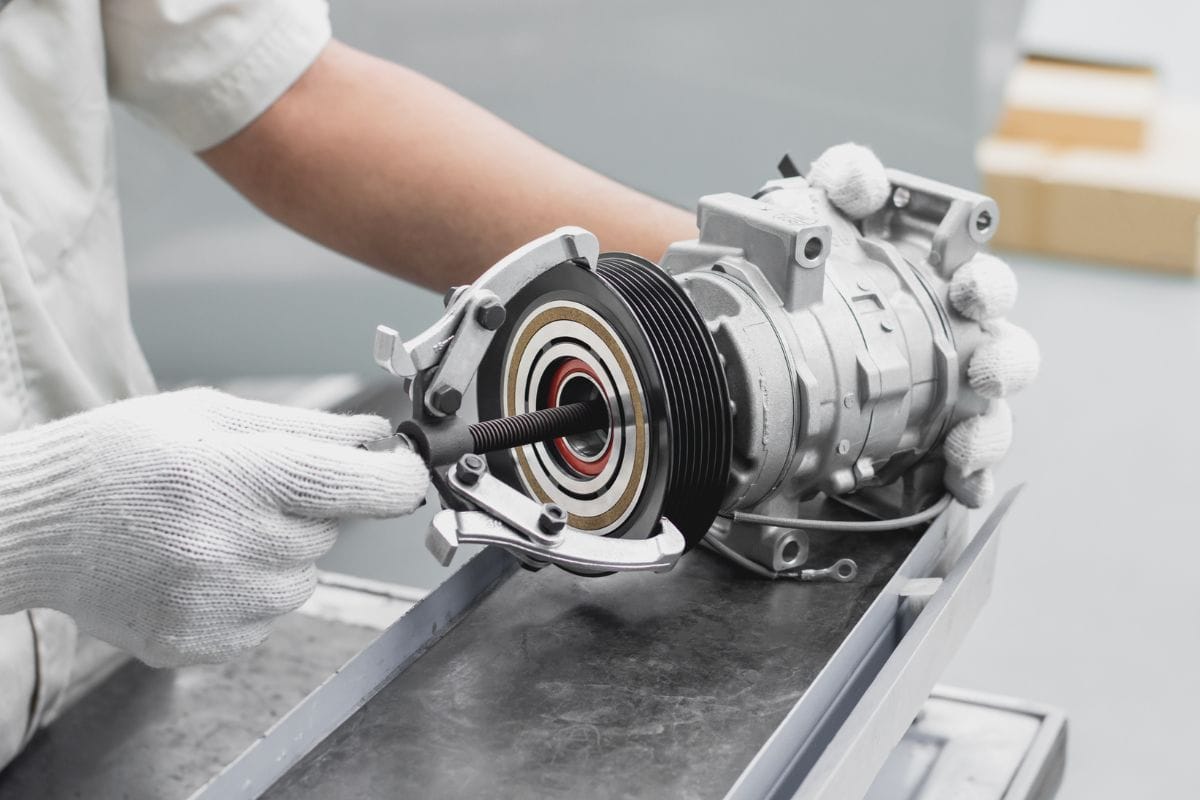

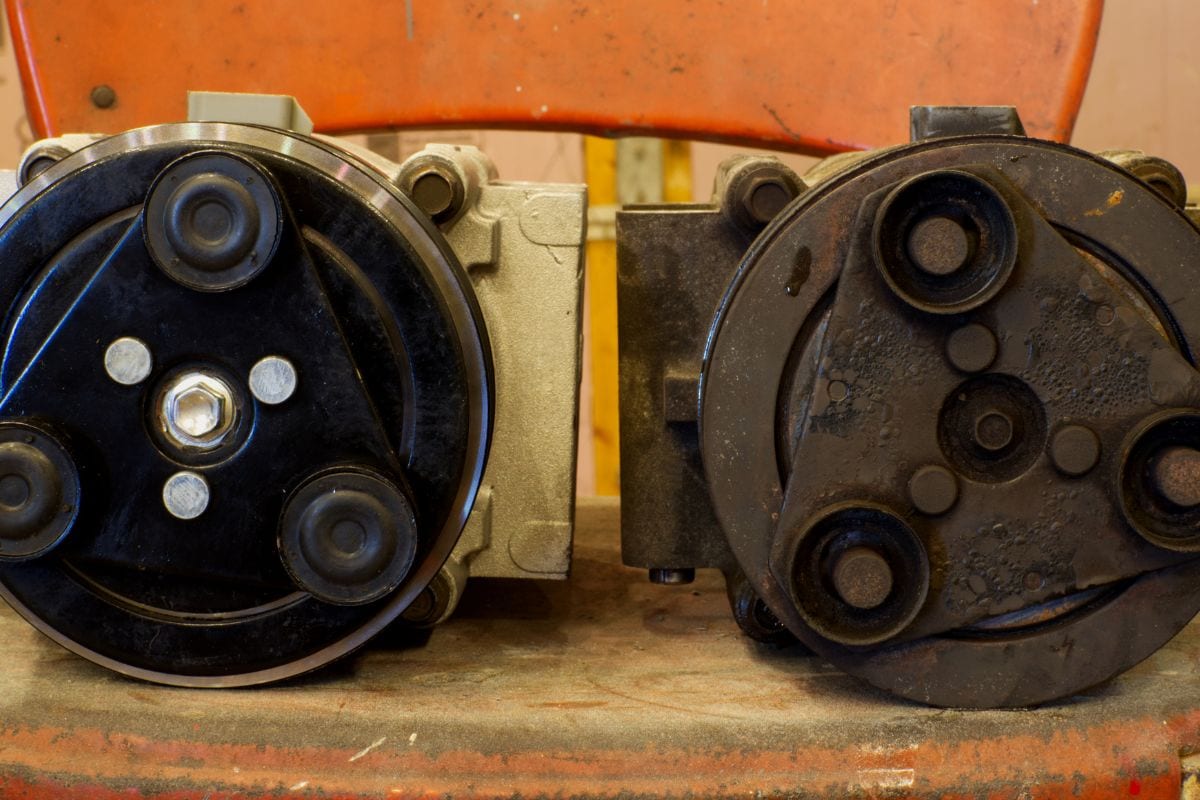

Replace The Bearing Or Pulley

You can no longer swap out the bearing or the pulley because most AC compressors have fixed components. Some models, meanwhile, still feature detachable pulleys that let you swap out the pulley alone.

How Could AC Pulley Failure Be Avoided?

Depending on the assembly, you'll need to replace the pulley or the complete compressor once you've determined that the AC compressor pulley is defective. It is more likely that a pulley will fail the longer you wait to replace it. As a result, you may harm the belt when it continues to seize up and may even become torn.

Purchasing a shorter drive belt can help you eliminate this risk up to the repair. You can route the belt to avoid the AC compressor pulley. After that, you ought to be able to operate your engine without worrying about noise or compressor failure. When your vehicle is fit for driving, make an appointment for the compressor pulley replacement at your neighborhood auto repair shop.

How to Manually Activate An AC Compressor Clutch

You can help identify the underlying cause of compressor clutch-related problems by providing the clutch coil with additional hot and ground sources. You can manually engage the clutch component on your air conditioner's compressor by following the procedures below.

Clutch Wiring Removal

The wire connection that corresponds to the clutch assembly on your compressor must first be located and disconnected. The wiring for this unit starts at the compressor's front end, located behind the air conditioner.

Determine the Power and Underground Cables

You need to figure out the location of the connector's ground and power pins. Consult the factory wiring diagram for your car should when in doubt.

Create Wiring Connections

You will now create wiring for the power and ground ends of the control circuit for your compressor. The connector intended for usage on the positive side of the wiring must have an inline fuse.

Secure The Connecting Wires

It's now time to connect your freshly created wiring. Securely attach the fused wiring between the positive post of your battery and the positive wire of your clutch coil. Make sure to link the connection of the wirings at the correct terminals.

What Indicates A Bad AC Compressor Clutch?

The air conditioning compressor is engaged and disengaged by an electrical clutch used by auto manufacturers. Try fixing the air conditioner compressor clutch on your car using the methods outlined below.

Increasing Cabin Temperatures

A faulty compressor could cause cabin temperatures to increase suddenly. When the clutch is inoperable, the compressor breaks down and can't control the refrigerant.

Loud Disturbing Sound

Odd noises are a common complaint when a clutch or other moving part begins to fail or seize. A screeching sound is due to a torn or leaking bearing. It's frequently preferable to replace the compressor entirely rather than attempt a repair because it can be difficult to pinpoint which component inside the compressor has malfunctioned.

Clutch Stopped Moving

The compressor pulley can connect or disconnect from the motor using the clutch, ensuring it only runs when it should. IIf the gear seizes, this will longer work. Without the clutch, the compressor would not draw any power from the engine, leaving you without air conditioning.

Unable To Switch The Air On Or Off

If the clutch breaks down can make the compressor inoperable. Instead, it happens much more frequently than the clutch will fail and prevent you from turning on the air. Without the clutch, the compressor would not draw any power from the engine, leaving you without air conditioning.

Final Takeaway

Regular maintenance is a must for car air conditioning compressors. A few factors that contribute to the compressor of a car locking up includes improper or subpar refrigerant, low coolant levels, and inadequate lubrication. You must periodically check your car's AC before anything becomes serious.

Hopefully, you have learned to identify the underlying causes of your AC compressor's failure. You should be able to focus on the problem at hand and resolve it using our explanations and solutions.

Investigate our linked posts for additional insights on car maintenance.