Boiler pipes are an essential part of any boiler system. They are responsible for carrying hot water and steam from the boiler to other parts of the system, such as radiators. But should boiler pipes be insulated? Let's take a look below.

The U.S. Department of Energy recommends insulating boiler pipes, as it can lead to reduced heat loss, improved system efficiency, and better overall performance. Insulated pipes also help protect against freezing in colder climates. In addition, any other boiler surface over 120 degrees Fahrenheit should be insulated to protect personnel from burns.

There are several reasons why you should insulate boiler pipes. In this article, we will discuss those reasons in detail. In addition, we will answer other frequently asked questions about boilers, so read on!

Why Should You Insulate Boiler Pipes?

Boiler pipes are typically made from steel, which is a poor conductor of heat. This means that when hot water passes through the pipes, it will cool quickly, causing energy loss and making the system less efficient. Insulation helps prevent this by trapping the heat and slowing down the process of cooling.

When you insulate boiler pipes, the temperature of the water can rise by 2-4 degrees. Thus, you can lower the temperature of your boiler by a few degrees, which can result in significant energy savings.

Additionally, if the temperature of the water is too high, it can reduce the life span of other components in the system, such as valves and pumps. Insulating pipes can help to prevent this from happening.

The other benefit to this is that you won't have to wait nearly as long for hot water to reach the taps. This saves both time and energy, meaning you can use less gas or electricity when using your boiler system.

The insulation also helps keep pipes from becoming too hot to touch, preventing serious burns should someone come into contact with them. All of these factors make insulating boiler pipes a good idea for most households.

With that, the Department of Energy recommends any part of the boiler system that reaches temperatures of 120 degrees Fahrenheit or higher be insulated for safety.

This includes the boiler surfaces, such as the boiler doors, valves, deaerators, access doors, pipe fittings, and return piping. It is also important to ensure that any insulation you use is fire safe and does not emit toxic fumes.

What Type Of Insulation Should You Use For Boiler Pipes?

There are different types of insulation you can use for boiler pipes and surfaces. Let's take a look at the options below:

High-Density Fiber Glass Insulation

This is one of the most popular insulation materials used today. It is fire resistant, lightweight, and effective at preventing heat loss. In addition, high-density fiberglass is also resistant to most toxic chemicals. You can find it in rolls or mats as well as pre-cut insulation boards.

The downfall of high-density fiberglass is that it has poor structural strength. It also is susceptible to moisture which can cause it to become brittle over time.

Mineral Wool Insulation

Mineral wool is another type of insulation that can be used with boiler pipes. It is fire resistant (up to 1,800 degrees Fahrenheit), durable, and very effective at preventing heat loss. It is also naturally moisture resistant, so it won't be affected by humidity.

Mineral wool also does a better job of soundproofing than other types of insulation. However, it can be detrimental if inhaled and may cause respiratory irritation. Be sure to wear protective gear when handling this material.

Spray-On Ceramic Insulation

This is an insulation material that is sprayed onto the boiler surfaces and pipes. It does an excellent job of preventing heat loss, and it is also nonflammable and moisture resistant.

The downside to this type of insulation is that it can be difficult to install if you don't have experience with this type of work.

Read more: Can I Use Expanding Foam Around Heating Pipes?

How Thick Should Boiler Pipe Insulation Be?

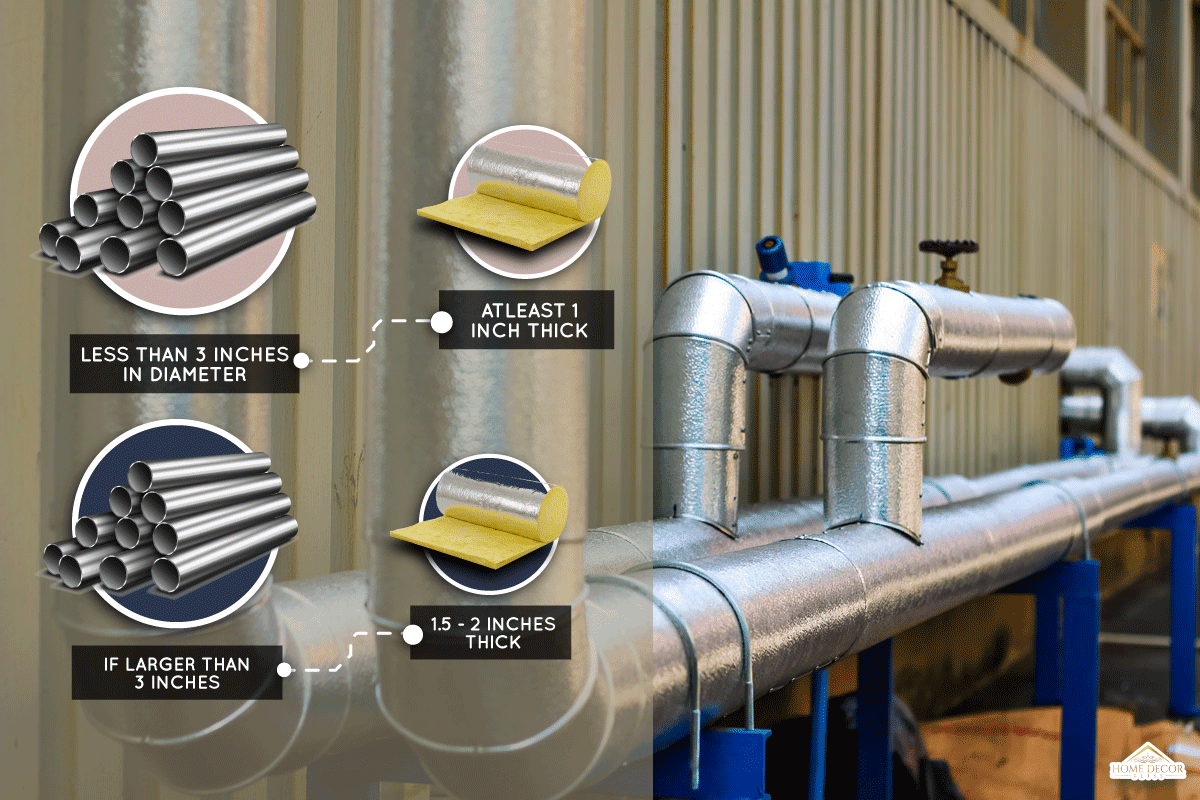

The thickness of water pipe insulation will vary depending on the thickness of the pipe. Typically, any pipe that is less than 3 inches in diameter should have insulation that is at least 1 inch thick. For pipes larger than 3 inches, the insulation should be around 1.5-2 inches thick.

It is also important to note that any insulation used on boiler surfaces should cover the entire surface of the component and not just part of it. This will ensure that all areas are adequately insulated.

If you are unsure about what type of insulation to use or how thick it should be, consult with a professional. They will be able to advise you on the best materials and thicknesses for your specific needs.

How Much Does It Cost To Insulate Boiler Pipes?

The cost to insulate boiler pipes can range widely depending on the material used, how large the area is, and any labor involved. On average, you can expect to pay $600 per 100 linear feet.

You may be able to get these costs down significantly. However, you may not get the same level of protection or safety that professional-grade materials and installation can provide.

However, this may be sufficient for a smaller home. For commercial buildings and large homes, every penny counts, so professional-level insulation is highly recommended. The upfront cost may be higher, but the energy and safety savings will be worth it in the long run.

Is It Cheaper To Insulate Boiler Pipes Myself?

Of course, any DIY project will be significantly cheaper than using professional services. However, it is important to remember that there are risks involved.

First, you have to put the time in to learn what type of insulation would be best for your needs. You also need to factor in the cost of materials, as well as any equipment needed.

On top of that, improper installation can lead to safety or energy savings issues down the line. So, while a professional may cost 2 to 3 times more, it is often worth the money for the peace of mind and assurance that your boiler pipes are properly insulated.

Ultimately, the decision comes down to you. If you have the time and knowledge to do it yourself, then go ahead—but be sure to use quality materials and take proper safety precautions. Otherwise, a professional may be the best option.

How Long Do Boiler Pipes Last?

On average, boiler pipes can last 50+ years when properly cared for. The life expectancy of a boiler pipe can be affected by how often it is used, the type of insulation material used, and the overall quality of the pipes.

Also, be sure to inspect your boiler pipes and the insulation regularly for any signs of damage or wear. If you notice anything out of the ordinary, contact a professional immediately.

Typically, you should have your plumbing pipes inspected every 2 years to ensure that they are in good condition. This will help you maximize the lifespan of your pipes' lifespan and reduce energy costs or potential safety hazards.

During the inspection, the professional may recommend having your pipes cleaned. This will ensure that your boiler pipes are running as efficiently as possible and that there aren't any underlying issues you might have missed.

Overall, taking proper care of your boiler pipes is the best way to ensure they last for many years. With a little bit of maintenance and upkeep, you can enjoy the benefits of a properly functioning boiler system for years to come.

How Do I Know If My Boiler Need To Be Replaced?

If your home is older, then your boiler pipes may be coming to the end of their life span. There are telltale signs to look out for that indicate when you need to replace your boiler pipes.

Leaks

Water leaks are the most obvious sign that you need to replace your boiler pipes. You may also notice an increase in energy costs or decreased efficiency in your system. If this is the case, then it is best to have a professional inspect them for any signs of corrosion or damage.

Odd Noises

If your boiler is making strange noises, this could be a sign that your pipes need replacement. These noises may include hissing, banging, or whistling, when the boiler is starting up, shutting down, or running.

No Hot Water

An obvious sign that your boiler is on its last legs is if it stops producing hot water. No matter how hard you try, the boiler won’t provide any hot water. In this case, it is time to call in a professional for an inspection and possibly replacement.

Increased Energy Bills

If you are checking the history of your energy bills and notice a sudden increase, then it could be time to replace your boiler pipes. This is especially true if you haven’t changed any of your regular usage habits.

This means that the boiler isn't working efficiently and may be on its last leg.

Overheating

Lastly, when a boiler overheats, it will shut itself off. This is a sign that an internal issue needs to be addressed. It's best to have a professional look at the boiler as soon as possible to diagnose the issue and determine if a replacement is necessary.

Final Thoughts

Insulating boiler pipes will save you energy costs and help to extend their lifespan. If you’re looking for an energy-efficient and cost-effective way to keep your boiler pipes in tip-top shape, insulation is the way to go.

Made it to the end? Here are other articles you might find helpful: