Installing a 5-ton AC unit into your establishment is a good idea. But you might be wondering about the ductwork that comes with it. To address this concern, we've done the work of compiling helpful information for you.

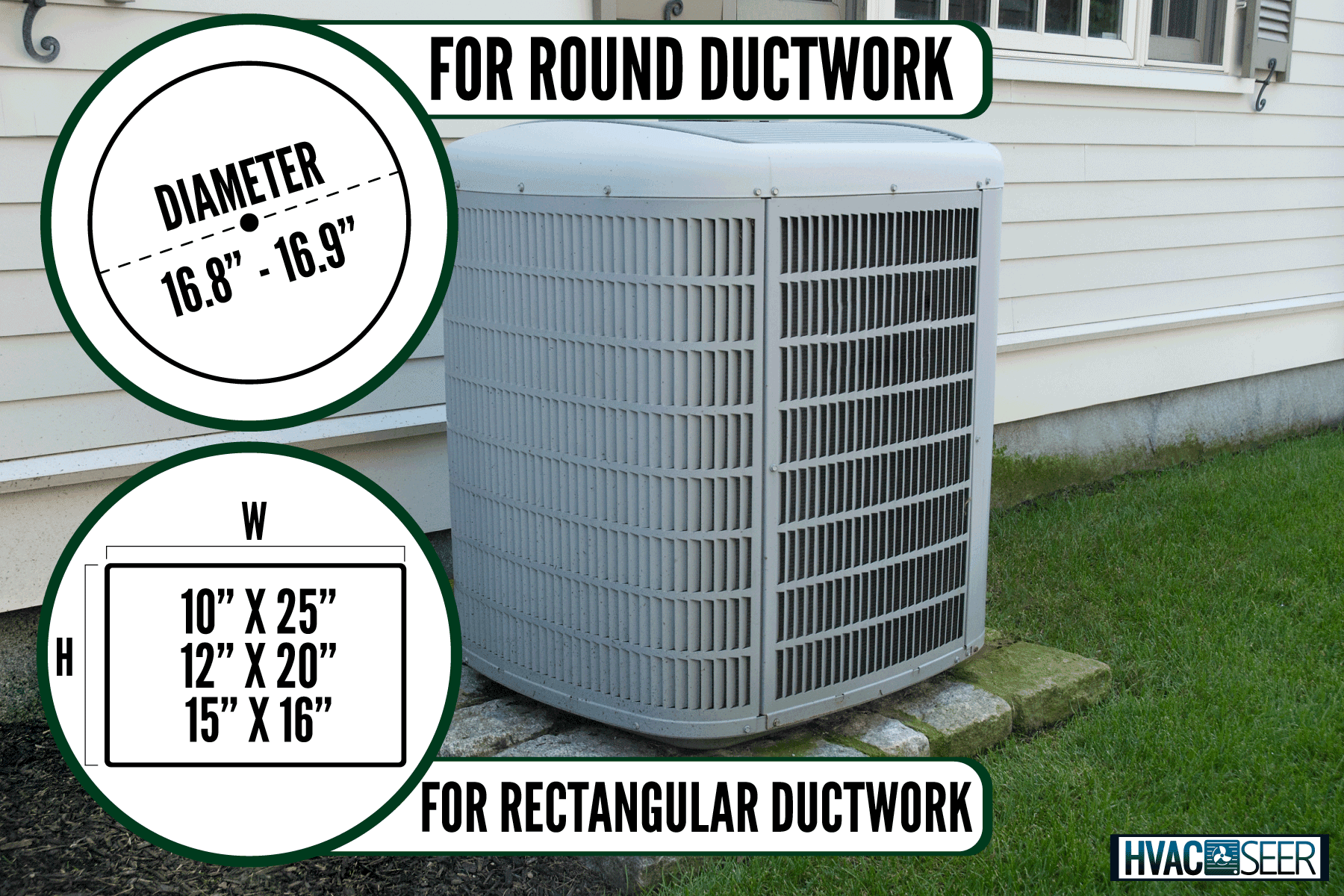

To accommodate the air flow rate of a 5-ton unit, the standard ductwork size estimate according to shape is as follows:

- Round shape (diameter):

- 16.8"

- 16.9"

- Rectangular shape (H x W):

- 10" x 25"

- 12" x 20"

- 15" x 16"

Duct sizing is a complex process greatly influenced by many factors. In this article, we will explore how air flow rate and shape affect choosing the ductwork size for a 5-ton AC.

Keep reading to learn more about the right duct size for your needs.

What Is Standard Duct Size For A 5-Ton AC?

Duct sizing is multifactorial. Standard ductwork sizes are guided by the CFM requirement of a unit.

Air flow rate, which is measured in cubic feet per minute (CFM), is one of the main factors in determining ductwork size for different HVAC systems.

Ductwork systems are sized according to a unit's CFM capacity.

The general rule in computing air flow rate is 400 CFM per ton (at ideal humidity levels). This means that a 5-ton unit will need to produce 2,000 CFM airflow in a humid environment for effective cooling.

With respect to room size, a 5-ton unit can completely replace air in a 2,000 cubic feet room in a minute. However, this is assuming that the room is a simple box or rectangle.

Airflow in rooms with irregular dimensions is more difficult to compute. This will affect the ductwork size. Here is an example of standard ductwork sizes that can accommodate the airflow volume of a 1-ton, 3.5-ton, and 5-ton AC unit:

| Unit Tonnage | CFM | Round Duct Size (inch diameter) | Rectangular Duct Size (H" x W" ) |

| 1 | 400 | 9.1"9.3" | 7" x 10"8" x 9" |

| 3.5 | 1400 | 14.6" | 12" x 15" |

| 5 | 2000 | 16.8"16.9" | 10" x 25"12" x 20"

15" x 16" |

Which Ductwork Shape Is Best?

The most common shapes of ducts are round and rectangular. Let's review the pros and cons of each.

Round Shape

Round ducts offer several advantages in facilitating air movement. For a start, it has a low contact surface and wide cross-sectional area and uses less material for the same air volume compared to rectangular-shaped ducts.

Here are more advantages to round-shaped ducts:

- Round ducts offer the least airflow resistance, meaning the equipment expends less energy.

- Less surface area will require less insulation material.

- Round ducts are available in longer dimensions. This lessens the need for costly field joints.

- Curved surfaces can contain low-frequency sound better.

- No angled corners also decrease the chances of dirt accumulation, making cleaning easier.

Round ducts offer a lot of advantages, but there are also downsides. The biggest drawback is perhaps the need for more clearing space for installation. Where round ducts disappoint, rectangular ducts satisfy.

Rectangle Shape

Rectangular ducts do not need a lot of clearance. They easily fit in ceilings and walls. This is why most building constructions make use of them.

But in fitting rectangular ducts in spaces, remember to keep the aspect ratio less than 4. The closer the ratio to 1, the more efficient the duct airflow.

While flexibility is a great quality, there are a few other things to keep in mind about rectangular ductwork:

- Pressure drop is higher, which causes equipment to expend more effort.

- More material is required compared to round ducts with the same flow rate.

- The joint lengths are limited in availability.

- Sealing the joints can be a challenge.

- Higher aspect ratios need proper support to control noise.

- Greater contact surface, more insulation material.

You can also read about How to insulate rectangular ductwork.

Why Insulate Ductworks?

Sealing and insulating are among the ideal practices of engineering and designing ductwork. You can make use of fiberboard or blanket-type insulation to minimize heat loss.

An inch-thick fiberglass blanket is most effective for keeping heat contained.

Check out this double bubble foil insulation on Amazon.

Since ducts sweat, insulation also helps control damage that may arise from wet duct surfaces. Including a vapor barrier in insulation specifications, such as aluminum foil, is essential.

For more insight, look into this article: "Should Ductwork Be Insulated?"

Which Material Is Best For You?

There is a variety of materials from which ductwork is made. Although ductwork is traditionally made of steel, non-metallic options are also available.

Metallic Ducts

The most common steel ducts are made from galvanized and aluminum steel. But in exceptional circumstances, copper and stainless steel are also available. Each varies in application:

- Galvanized steel - The most common material for ductwork, as it does not easily rust. It also has an excellent soundproofing and insulation degree.

- Aluminum - Preferred for rooms with high humidity, it is usually paired with fiberglass insulation for better heat control.

- Stainless steel - Mainly used in rooms with high fumes and moisture content, like kitchens.

- Copper - Used for chemical exhausts and aesthetics.

- Carbon Steel (Black Iron) - Used mainly in industrial settings heavy with abrasive material, this reinforced metal is wear-resistant.

Since ACs have low pressure, reinforced ductwork is not needed.

Non-metallic Ducts

Plastics or foam boards are used as an alternative to metallic ducts. They are cut and shaped so that the required cross-sectional dimensions are achieved. The following make suitable non-metallic ducts:

Fiberglass Reinforced Plastic (FRP)

Corrosion-resistant, with good sealing, insulation, and acoustic control. Good ductwork material for places with chemical-laden atmospheres and underground duct systems.

However, the material is heavier and more costly than metallic ducts, and code acceptance may be an issue.

Polyvinyl Chloride (PVC)

It has the same uses, mainly with FRP, but may not do as well with thermal control. PVC ducts also share the same disadvantages as FRP.

Fabric

Also known as textile, it is made of a special permeable polyester. It plays a vital role in areas needing even air distribution. This kind of air distribution system works best unconcealed.

Flex Duct

It has an inner polyester film lining supported by a corrosion-resistant helix wire, jacketed by a thick fiberglass blanket for insulation and vapor barrier. This usually branches out from metal and board ducts.

While it is good to have options, there are downsides to using non-metals.

Even with good quality control and local manufacturing standards, non-metals don't always perform well when exposed to fires. Also, the building code may pose limitations on the use of such materials.

Are Ductworks Necessary?

We cannot blame you if you have two minds about installing ductwork into your home. Apart from the complexity, it is expensive. But there are substantial long-term benefits to installing ductwork:

Good indoor air quality

Functional ductwork is instrumental to good indoor air quality. The main idea is that there is good air exchange and even distribution.

A study by the Environmental Protection Agency (EPA) claims that indoor air spaces tend to have more pollutants than outdoor ones.

There are three main strategies to control indoor air quality:

- Removal or isolating pollutant sources from people through physical barriers, air pressure relationships, or controlling their use.

- Eliminating indoor pollutants through ventilation.

- Use of filtration to clean indoor air of pollutants.

Ductwork contributes to these strategies, as it affects air movement (pollutant movement) in a room. A sound duct system promotes the ideal frequency of air exchange.

Note that filters and air purifiers can be easily installed in ductwork systems.

More energy savings

Compared to ductless systems, installing ductwork will be more cost- and energy-efficient in the long term.

Apart from being an efficient air distribution system, low maintenance is needed. We recommend that ductwork be sealed and insulated correctly to optimize energy savings.

Better comfort

Proper ductwork design will ensure even temperature distribution in every room. This means you don't have to worry about walking interchangeably into warm and cool rooms.

Innovations in this industry have allowed for an improved indoor atmosphere.

What Ductwork Size Do I Need For My Home?

In custom-fitting ducts into your home, you need to consider details such as the size of each room, the number of stories, and occupants.

However, for a much simpler illustration, we will follow the CFM rule of thumb to determine your standard ductwork size.

This is the general formula for individual room size:

CFM for each room = Room size (sq. ft.) x (Unit Tonnage x 400)/ Total sq. ft. of house

Following the average floor area of a single-family American home of 2, 312 sq. ft. with four identically-sized rooms and a 5-ton unit, the calculation goes:

CFM = 578 sq. ft. x (5 x 400) / 2,312

CFM = 500 CFM/ room

This means a ductwork size for a 5-ton unit of 2,000 CFM will branch out to deliver 500 CFM to each room. From here, professionals will determine the size of your ductwork.

With a software-aided process, they will factor in friction loss, pressure drops, cross-sectional areas, and airflow speed to develop the appropriate ductwork size for your home.

For existing infrastructures without ductwork, you can explore other choices in this article: "Older Home With No Ductwork? Here Are Your Air Conditioning Options."

In a Nutshell

Finding the correct ductwork size for a 5-ton AC unit is easy. Matching the unit's required CFM will help you find the right estimated size available on the market.

It is retrofitting that poses the real challenge. That's why it is important to find contractors keen on following best practices and the latest trends and technologies in the industry.

Ductwork sizing can be confusing and intimidating, so it's best to leave it to the pros. What homeowners need to focus on is knowing the benefits ductwork can bring into their homes.

To discover the health-related effects of ductwork systems, check out this other post: