It's a terrible experience when the bolt holding the AC compressor in place breaks while being removed. At that moment, all you might want to do is freak out, and you can't even begin to imagine how to fix a bolt that has broken off in a casting. Well, worry no more! Here is what we discovered after doing research on these issues for you.

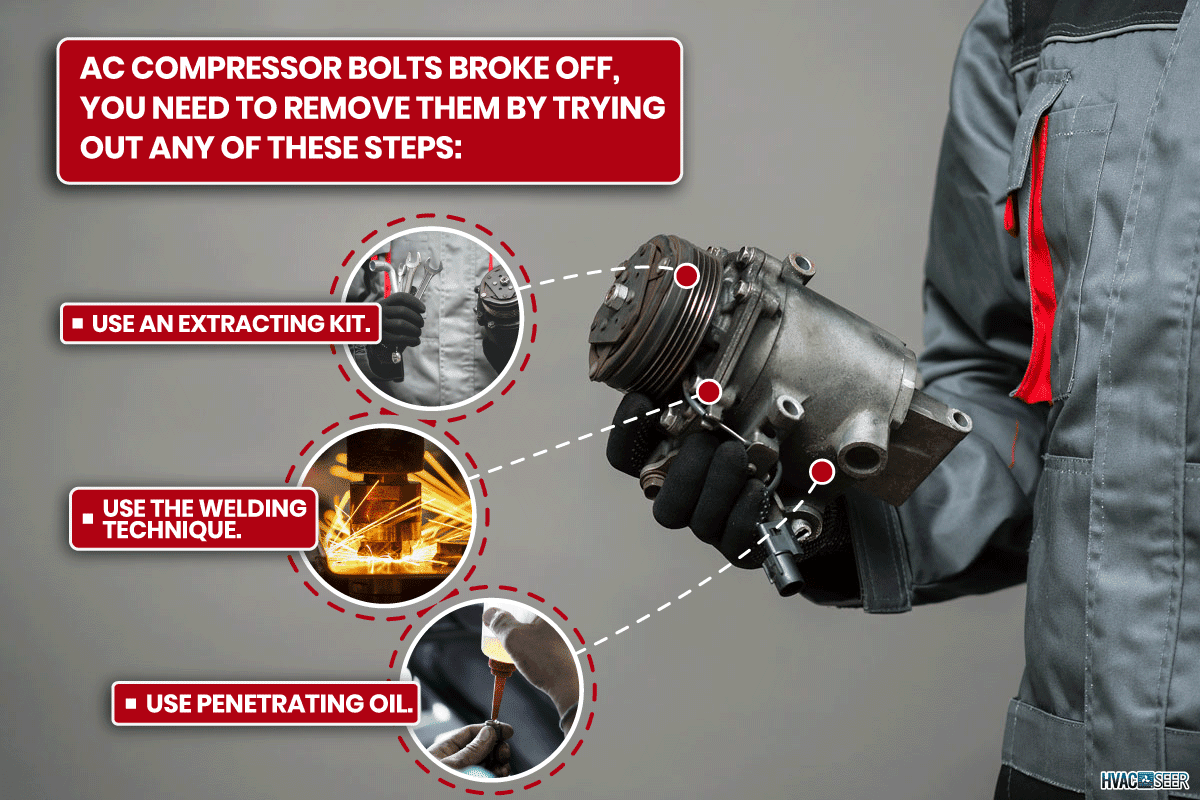

When AC compressor bolts broke off, you need to remove them by trying out any of these steps:

- Use an extracting kit.

- Use the welding technique.

- Use penetrating oil.

In this article, we'll talk about several tools, techniques, and advice for removing broken bolts. If you're interested, keep reading, and we'll provide you with helpful advice in the next sections.

Removing AC Compressor Broken Bolts

We've discovered that some techniques work better for removing bolts than others. Learn how to quickly and easily remove broken bolts by following these instructions:

Use An Extracting Kit

Misfortune has the wonderful benefit of inspiring brilliant discoveries and solutions. Drill a pilot hole or other indentation into the hardware, then insert the extractors into the hole.

This is how screw extractors operate. You can turn the extractor so that the edges will snag on the pilot hole and turn the bolt out. This method usually frees you from a jam and works on mildly jammed bolts.

Drifting it out

It might be possible to drift the bolt out if it is not completely seized. You might be able to get a screwdriver or tiny chisel behind the burr if it has one and tap it out with a light hammer where it broke off. In the event that this is unsuccessful, spin the shaft using a center punch by tapping a hole close to the edge.

This technique requires extreme caution. If it does not come out after a few tries, you run the risk of damaging the threads or widening the head, which will only serve to tighten it even more.

Using a left-handed drill bit to make a hole in the head

When you use this on the bolt that was sheared off, it automatically turns it in tighter because drills typically turn in a clockwise orientation. However, if you use a left-handed drill bit and choose reverse on the drill, it cuts in the other direction and applies power that naturally turns the stud out.

Thanks to pressure, friction and heat, there is a good likelihood that the left-hand bit will bite into the bolt and turn it out for you as you drill.

Watch this video for a demonstration of the extraction procedure:

Using a bolt extractor to release

Another choice is to use a bolt extractor tool to free the sheared-off bolt. The screw extractor snags a damaged bolt and spins it free from its attachment point with threads that resemble drill bits traveling in the opposite direction.

Screw extractors have their own set of issues, the worst of these being the chance of breaking inside the screw that is being removed. The work of extracting the first screw is made more challenging by the extremely hard material and the impossibility of drilling through the first screw extractor.

Drilling it out

If none of these solutions work, your only option is to drill out the screw or bolt and retap a fresh set of treads. This is a labor-intensive last resort.

Pros and Cons

- Using a bolt extractor is a far more reliable and consistent repair.

- With the proper equipment, a technician of any skill level can complete it.

- As opposed to pulling the complete engine head, this may be the best choice when there is little space.

- Without the right equipment, a challenging task might become a complete nightmare.

- Using inexpensive drill bits and extractors nearly always results in subpar work.

Check this broken bolt extractor on Amazon.

Use the Welding Technique

Welding training or the capacity to hire someone to do it for you are prerequisites for this method. This strategy implies you have welding experience and have access to a welder.

For this job, you have to choose a MIG welder instead of an arc welder. The latter produces a lot of slags, which get into the weld. However, getting the sheared-off stud out is the main goal here, and the first welder will accomplish the job just fine.

Releasing a sheared-off bolt

A nut of the same size can be obtained and welded over the sheered head of a stuck bolt, which is one of the more effective methods for doing so. The metals' differing rates of fractional expansion, caused by heating and chilling, aid in the disintegration of the metals. Once it has cooled, use a breaker bar to pry the freshly welded nut out.

Fixing a Broken Stud

Choose a nut or flat washer with an inner diameter that is approximately the same as the threaded bolt's size to start. Attach the flat washer, nut, or both to the bolt, and then use a welding gun to fuse the nut's interior to the shattered bolt top.

Next, take the nut and bolt apart using a wrench. For instance, titanium alloy bolts, which are common in turbo-charged engines, require a lot more care and heat to fuse.

In addition, accessing low-vision, hard-to-reach locations with a welding head brings its own set of difficulties. Last but not least, not all situations can be solved by welding. Like other fixes, not every method is applicable in every circumstance.

Pros and Cons

- With the proper application, welding can be speedy and relatively inexpensive.

- It requires a thorough understanding of welding and heat transfer.

- It's time-consuming due to equipment setup, heating, cooling, and repeated tries.

- Because there are so many different metals in modern engines, it can be exceedingly challenging to weld them together.

Click here to see this portable welding machine on Amazon.

Use Penetrating Oil

Strong penetrants offer an unmatched solution for releasing rusted and corroded objects. Penetrating oil has long been successfully utilized to remove stuck metal parts without the potential dangers of heat application. While heating calls for constant attention, penetrating oil offers lubrication and corrosion protection that heat cannot.

Use penetrating oils and heat in alternating steps rather than simultaneously. Before using heat or an open flame, be careful to wipe any oil from the part's surface and the surrounding area.

Apply the penetrant, thoroughly cooling the part after a challenging job. Instead of using a torch whenever rust or corrosion slows you down, use a high-quality penetrating oil. Compared to using heat, you can finish difficult tasks more safely and effectively.

Click here to see this penetrating oil on Amazon.

How do you remove a broken aluminum bolt?

With a metal file, smooth off the top of the bolt until the surface is absolutely flat. On this smooth surface, set a bolt removal bit. Once the bit has locked into the bolt, turn it. The bolt can be turned and removed from the metal by turning the bit back to the left.

Can you heat up aluminum to remove the bolt?

Try heating the nut or bolt using a propane flame if it still won't move. After several minutes of torch heat, let the nut or bolt cool before repeating the process. To prevent a fire when using a torch to warm a connection, make sure to keep all combustible objects far from the vicinity.

What happens if the AC compressor breaks?

The AC stops working when a compressor malfunctions. Even though the fans may still be running, no cool air will be coming out of the vents. A homeowner must make a significant decision regarding what to do next because the compressor is such a crucial component and is pricey to repair.

In Closing

We hope this article has given you insight into how to deal with your broken bolt concern. Now that you have gone through the basic methods for removing broken bolts, you ought to have a professional inspect your AC compressor as soon as you can to avoid more damage.

If you enjoyed reading this article, you might want to check out these related posts: