The most typical issue with gas furnaces is a faulty gas valve. And these valves come in a wide variety of shapes and configurations. You may wonder whether you can interchange gas control valves. We researched this question and have the answer below!

Each gas control valve has a specialized purpose, so switching these valves is not advisable. The brand-specific connections and valve designs ensure that the gas supply to the burner and pilot corresponds to the heater's BTU output.

Gas valve management is an important topic. You must have extensive knowledge and expertise to keep yourself informed and directed. Continue reading to learn about the compelling arguments for not interchanging gas valves. With that said, let's begin!

Can You Swap Out A Gas Control Valve?

Swapping gas control valves is not recommended. Since each control valve serves a specific role, you would need to spend time and money testing the gas valves for compatibility to ensure operational safety and enhance the appliance's effectiveness.

You may even breach the law or void the furnace's warranty if you interchange the gas control valves.

Should You Replace A Gas Valve Yourself?

Here are some reasons against checking and repairing a damaged gas valve in a furnace yourself:

Safety Concerns

Working with so many elements can put you and others in danger if you don't have the right tools and training. A gas leak is a real risk when using a gas furnace.

So, don't try to test or repair a furnace gas valve if you can't tell whether it's on or off.

Check out this gas control valve on Amazon.

Possible Damage To Your Furnace

A lack of knowledge and expertise is a recipe for disaster, which can quickly lead to new issues. If you skip a procedure or perform it incorrectly, your furnace may sustain additional damage.

This Will Take A Long Time

Testing and replacing gas valves necessitate specialized hardware, supplies, and tools, which can be costly. Furthermore, learning how to use the tools and completing these tasks takes time.

An HVAC specialist can complete the job more quickly and securely than you can.

Most DIY Repairs Won't Work/Aren't Safe

Many jurisdictions prohibit anybody other than a licensed HVAC professional from checking or making changes to gas valves because of the risk that a leak could cause an explosion.

This regulation protects you and your neighbors.

How Do I Choose A Gas Valve For My Appliance?

Selecting the best gas valve can be difficult because of the numerous options available and the purposes they serve. Below are some gas valves commonly used in the oil and gas industry.

Gate Valves

Gate valves help you to open or close a pipeline. Therefore, the gate valve is ideal when managing the flow rate.

The presence of an actuator ensures that you can use the valve even for slurry fluids like crude oil since it opens the valve fully.

Check out this heavy-duty gate valve on Amazon.

Ball Valve

The S-shaped tube inside the ball valve often results in a higher pressure drop than other valve types. So, these valves are ideal when pressure control is required.

They are particularly good at tasks like flow control and throttling.

Check out this stainless steel ball valve on Amazon.

One-Way Valve

A one-way valve, or check valve, is extremely useful in gas refineries because it allows fluid to flow forward while preventing it from flowing backward.

Backflow restriction prevents product cross-contamination. Unlike other valve types, this type requires no actuator.

Check out this universal check valve on Amazon.

Slim Valve

The slim valve, also known as a plug valve or an on/off valve, controls flow while causing less pressure drop. It regulates flows and tapered "plugs" inside the valve body.

This valve is often used to produce biogas from crude oil waste products.

See this butterfly valve with tri-clamp on Amazon.

Quarter-Turn Valve

This valve is similar to a ball valve because it has instant shutoff. However, it can also open and close sequentially.

These valves are small, portable, and simple to operate. They control high-pressure pipelines while allowing for simple material flow.

View this quarter-turn brass shutoff valve on Amazon.

Overpressure Relief Valve

This type of valve is usually installed directly before a regulator and is intended to stay open until a significant change in pressure is detected.

The valve is also a relief and safety valve and is critical in the oil and gas industry for preventing accidents.

See this temperature/pressure relief valve on Amazon.

Pilot Safety Valve

The pilot safety valve is a tiny valve that regulates the flow feed between piloted valves.

The valve provides a small and easily controllable intake to keep a much pressure or flow that would otherwise require a significantly greater force to operate.

View this knob for a gas pilot safety valve on Amazon.

How To Troubleshoot A Faulty Gas Valve

The gas valve is a good place to start diagnosing a gas furnace. If you discover that the valves are not working, below are a few troubleshooting steps you can take.

- Check whether the pilot light is on. If it is off, refer to your owner's manual for a guide on relighting the pilot light.

- Examine the thermopile for the correct voltage. Change the thermopile that is broken and does not open. The safety valve must have enough electricity to remain open.

- Conduct safety measures. At this point, check the voltage levels of each safety component in the circuit. If nothing works, then you must replace the gas valve.

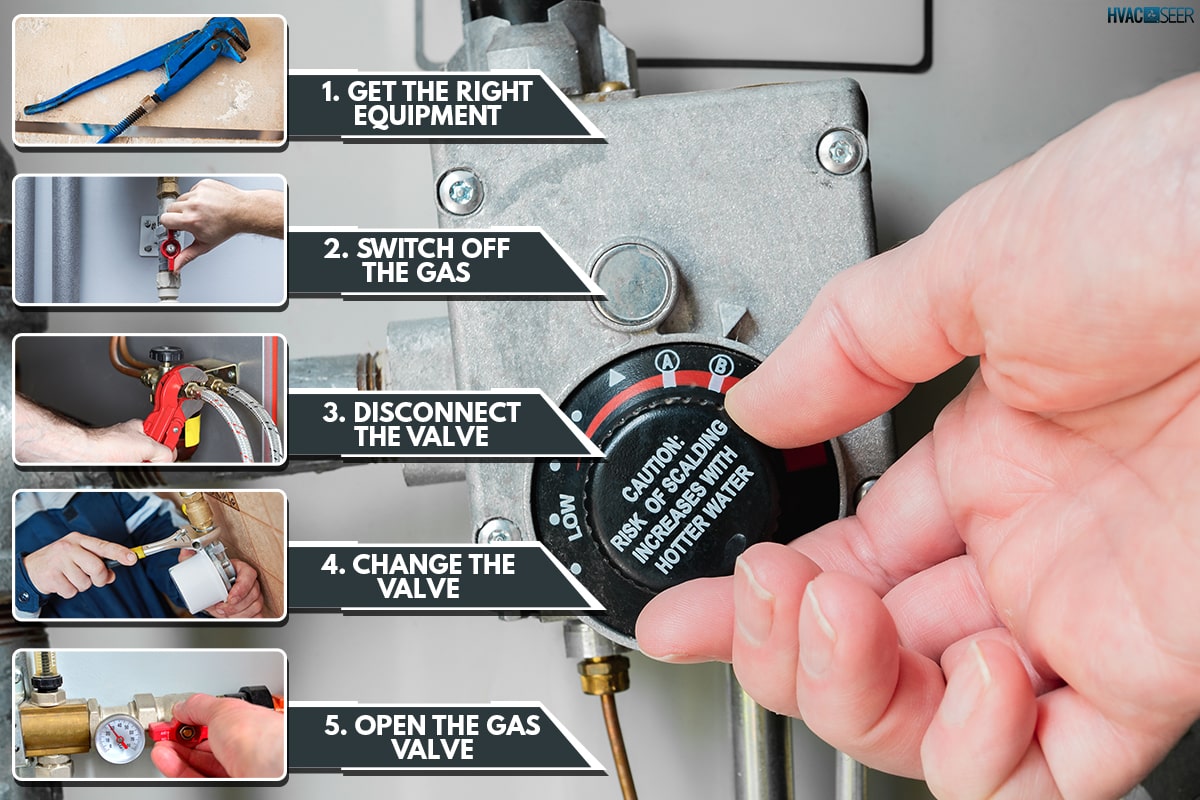

How To Change A Gas Control Valve

As previously stated, only experts should replace a gas valve. You can, however, change the gas valve on your own if you feel safe and comfortable doing so. Here are the steps to do this below:

1. Get The Right Equipment

Most tool sets have everything you need to complete this project. If you don't already have one, you'll need to buy or borrow one. The gas control wrench is essential since you use it to set up and detach valves.

It is also advisable to keep the number of a local electrician handy in an emergency. So, ensure you get that before you start the exercise.

2. Switch Off The Gas

Begin by identifying the problem, then switch off the gas. To do this, go to the main line and turn off the gas. Then turn off any remaining home lines.

If you detect a faint gas odor, open the doors and windows immediately.

3. Disconnect The Valve

Use the tools you've gathered to remove the valve. Valve removal is safe when done with a valve removal tool. Using a valve removal tool also saves you time.

4. Change The Valve

Install the replacement valve using the same tool. Check that the valve's specifications match the original. For your safety, you should avoid installing a low-quality gas control valve.

5. Open The Gas Valve

Before starting, double-check that everything is in working order. If this isn't the case, call an HVAC professional and turn off the gas until they arrive.

Here is a visual guide to changing the gas control valve in a water heater:

Our Final Words

Most natural gas and propane valves are not interchangeable. So, purchase a valve that fits your gas type. To ensure that the valve fits firmly and accurately to the original, use a factory-authorized replacement component.

Please refer to the gas valve's model number, serial number, and manufacturer's name to locate it.

Never attempt to interchange gas valves because it may lead to a conflagration, explosion, or fire. If you smell gas, immediately turn off the gas and contact a technician for immediate repairs.

And while we have your attention, check out these related HVAC articles: