When it comes to home renovations and plumbing work, homeowners often face the question: can you cut floor joists for plumbing? Cutting notches or holes into floor joists to accommodate plumbing pipes is a common practice, but it must be done carefully to maintain the structural integrity of the joists.

It's essential for homeowners to consult with professionals before undertaking such modifications to their floor joists, as improper cutting or drilling can compromise the stability and safety of the floor structure. In this article, we'll talk about the best ways you can cut your floor joists for your plumbing needs.

Understanding Floor Joists

Floor joists are an essential component of any building structure, as they serve as the primary support system for flooring within a building. This section takes an in-depth look at the purpose of floor joists, the common materials used, and load-bearing considerations.

Purpose of Floor Joists

Floor joists help distribute the load from various building components, such as walls, floors, and furniture, evenly across the entire floor structure. By doing so, they prevent sagging or cracking and ensure the structural stability of the building.

Additionally, joists create a space for plumbing, electrical, and HVAC installations to run through within the floor system.

Common Materials Used

Various materials can be used in constructing floor joists, with the following being the prevalent choices:

- Wood: Traditional and widely used, wooden joists such as solid lumber and engineered wood (including I-joists and laminated veneer lumber) provide excellent strength and flexibility, as well as ease of installation.

- Steel: Steel joists, or "C" joists, are lightweight and non-combustible, offering increased fire resistance and structural strength. They are often used in commercial buildings or situations requiring long spans without support columns.

- Concrete: Precast concrete joists are less common but provide exceptional durability and resistance to moisture and insects. They are more commonly used in multi-story residential or commercial buildings.

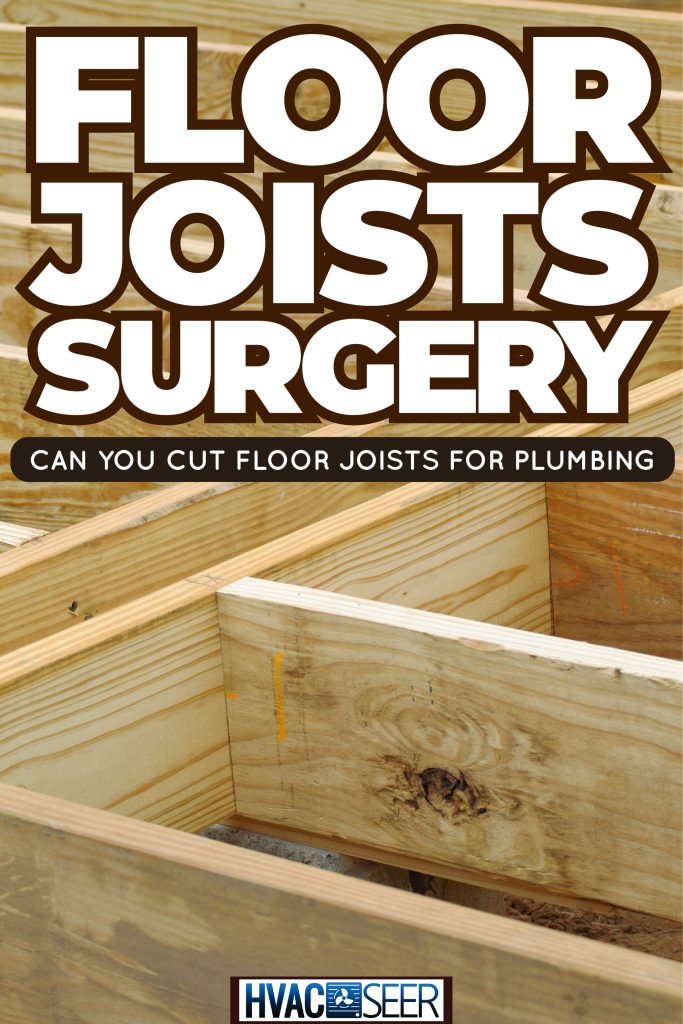

Load Bearing Considerations

One of the critical factors in designing floor joists is the consideration of their load-bearing capacity. Joists must be able to safely support both dead loads (permanent weight from building materials) and live loads (temporary weight from occupants and furniture). To ensure proper load-bearing capacity, it is crucial to consider:

- Joist spacing: Typical spacing for joists ranges from 12 to 24 inches on center, with tighter spacing providing better weight distribution and structural support.

- Span length: The distance a joist can span is affected by the size (width and height) and strength of the joist's material, as well as the spacing between joists.

- Notching and drilling: Cutting or modifying joists can impact their structural integrity. It is necessary to follow proper guidelines when making adjustments for plumbing installations.

It is essential to consult with a professional engineer or building codes for specific requirements and guidelines when constructing floor joists and installing plumbing systems.

Cutting Floor Joists for Plumbing

Properly cutting floor joists for plumbing installations is important in maintaining the structural integrity of a building. It is possible to make cuts for pipes and other fixtures without compromising the strength of the joists, but care must be taken to follow best practices and local building codes.

Potential Issues

Improper drilling, notching, or cutting of floor joists can lead to various problems, such as reduced load-bearing capacity, weakened support structures, and potential code violations.

For instance, cutting notches or holes too large or in the wrong location can cause the joist to be unable to support the load it was designed for and compromise the structure's stability. This issue can be dangerous, and the occupants of the house may be injured if the stability is compromised.

Best Practices

When cutting floor joists for plumbing, adhere to the following best practices to ensure structural integrity and code compliance:

- Review local building codes and manufacturer guidelines for engineered floor joists prior to making any cuts or drillings.

- Limit hole diameter to a minimum size that's appropriate for the specific joists being used, ensuring adequate support remains intact.

- Position holes at least 2 inches away from the joist's edge to maintain strength and stability.

- Properly slope pipes or other fixtures—taking into account bore size and floor span—to ensure adequate drainage and flow.

Alternatives to Cutting Floor Joists

Cutting through floor joists for plumbing can be safe if done correctly; however, there are a few alternatives. These alternatives can help you avoid violating any building codes and prevent potential structural damage. This section will discuss two such alternatives: rerouting plumbing and using specially designed joists.

Rerouting Plumbing

One alternative is to reroute the plumbing in a way that avoids the need to cut through floor joists. This can be done by:

- Running pipes in the spaces between the joists, which can help preserve the structural integrity of the floor.

- Routing the plumbing through the walls in combination with wall-mounted fixtures.

- Exploring different layouts for the bathroom or plumbing system, which might remove the need to cut through the joists.

These methods require careful planning and might involve some additional costs or design limitations, but they help maintain the strength and stability of the floor structure.

Using Specially Designed Joists

Another alternative is to use specially designed joists that have pre-drilled holes and built-in spaces for running pipes. These joists come in various sizes and materials, like engineered wood or steel, and can offer the following advantages:

- They preserve the structural integrity of the floor as they have been specifically designed and tested to accommodate plumbing in their openings.

- They can facilitate plumbing installation and save time by reducing the need for onsite drilling through joists.

- The pre-drilled holes and openings can help achieve proper slopes for drainage while adhering to local building codes and regulations.

Using specially designed joists is a proactive approach that can save time, money, and prevent potential future issues. Of course, this option may not be viable for existing structures, but it should be considered when planning new construction or a significant renovation.

Repair and Reinforcement

When it comes to cutting floor joists for plumbing, it's important to know how to properly repair and reinforce the affected joists to maintain the structural integrity of the building. Here are some of the methods for reinforcing cut joists and when to consult a professional for assistance.

Reinforcing Cut Joists

There are several methods to reinforce floor joists that have been cut for plumbing purposes. Some common techniques include:

- Sistering: Sistering involves attaching a new joist alongside the cut joist, essentially doubling the thickness of the original joist. Be sure to use epoxy or urethane glue and stainless steel deck screws to tie the new joist securely to the damaged one.

- Bracing: Adding cross braces or bridging between the joists can redistribute the load and provide additional support for the cut joist.

- Using Post Jacks: In some cases, installing a post jack under the cut joist can provide additional support by transferring the load directly to the ground or a foundation.

When to Consult a Professional

Cutting through floor joists for plumbing should be done with caution. If you're unsure about the proper way to cut, reinforce or repair floor joists, it's best to consult a professional.

Structural engineers or experienced contractors can help assess the situation and provide expert guidance on what techniques are most suitable for your specific project.

Additionally, if you notice any signs of sagging, excessive deflection, or bounciness in your floors, it's a good indication that the floor joists may need further reinforcement or repair, and consulting a professional is highly recommended.

In Closing

Now that you've taken a look at these considerations, we now know that cutting floor joists for plumbing is possible, but it must be done with utmost care and consideration to maintain the structural integrity of the floor. It is crucial to follow building codes and local regulations when drilling, notching, and cutting joists.

If you're not sure about the best way to go about with your plumbing and floor joists concerns, consulting a professional is always the best option. This will save you time, and it will ensure that your home and family will be safe.

Read more about floor joists here: Should You Insulate Floor Joists In Basement?