We all love expanding foam guns. The name sounds fun but can give exceptional results, so it's like working and playing simultaneously. However, some of us have run into trouble with them once in a while.

If you are having trouble getting your foam gun to dispense, don't worry! We've researched and compiled a list of potential problems and solutions.

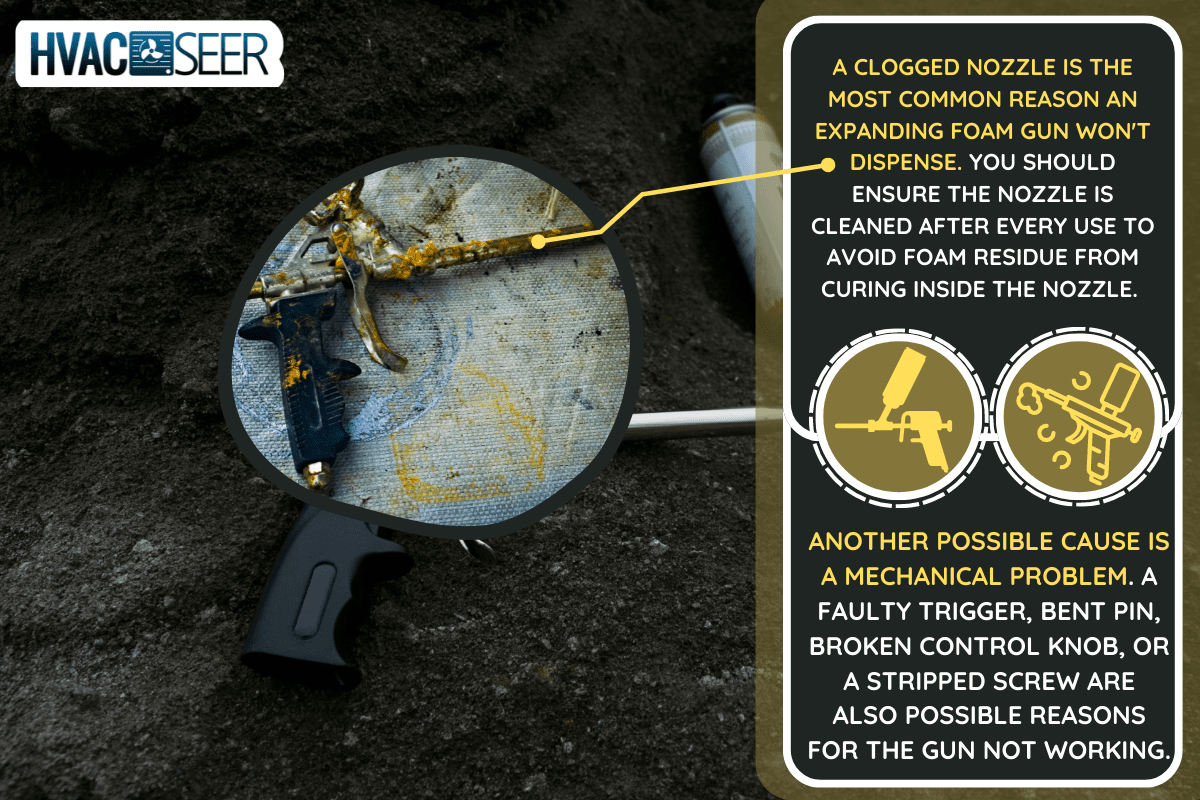

A clogged nozzle is the most common reason an expanding foam gun won't dispense. You should ensure the nozzle is cleaned after every use to avoid foam residue from curing inside the nozzle.

Another possible cause is a mechanical problem. A faulty trigger, bent pin, broken control knob, or a stripped screw are also possible reasons for the gun not working.

Expanding foam guns are great tools for DIY projects and are relatively inexpensive. However, just like any other tool, they are not immune to malfunction.

If you notice that your expanding foam gun is not working correctly, keep reading as we provide instructions on troubleshooting and resolving the common issues.

What Is An Expanding Foam Gun?

An expanding foam gun is a tool used to install foam insulation. Aside from insulation, the foam is usually applied to the seams between the walls and floor and seals cracks and holes. It can also be used for other purposes, like sealing gaps around doors and windows.

An expanding foam gun looks and works like a gun. It has a trigger that fires the foam out of the nozzle. The foam expands into the cracks and gaps and then cures.

The foam gun has a can adapter that holds the foam can in place. You adjust the control knob to regulate the amount of foam you want to shoot.

The expanding foam expands and cures very quickly, so you need to target the cracks and gaps with the nozzle as accurately as you can as you press the trigger.

Common Reasons Why An Expanding Foam Gun Fails To Work

If you've used an expanding foam gun before, you might have encountered numerous frustrating situations. From being unable to shoot foam to being unable to control the flow rate, these are just a couple of examples that can go wrong with your expanding foam gun.

How to Troubleshoot Your Expanding Foam Gun

If you encounter any of these issues, the first thing you should do is check the following areas:

1. Spray Foam Can Is Running Out Of Foam

In many cases, an expanding foam gun may not shoot foam when the spray foam can is empty. Make sure that you have an adequate supply of foam to shoot. You'll know if you're running out of foam because the can will noticeably become lighter.

2. Check The Barrel And Nozzle

An expanding foam gun can sometimes stop operating due to clogging of the barrel. It is the most common reason why it stops working. This issue is especially common in situations where the gun is used and stored without cleaning.

Clogs can occur due to the curing or hardening of polyurethane foam inside the barrel, obstructing airflow.

You can also check the needle at the tip of the nozzle if it's clogged. Removing the nozzle using an adjustable spanner will expose the needle. You'll likely have some hardened foam sticking to it.

3. Mechanical Problems

These are some common mechanical problems with the expanding foam gun. We have compiled them so you can know what to look out for and what to do when encountering one of these issues.

Stripped Screw

This is highly unlikely to happen with expanding foam guns, but it's possible, especially if your foam gun has been around for years and you've been screwing and unscrewing the barrel after every use for cleaning.

The screw can be stripped because of this.

The easiest way to fix this is to remove the existing screw and install a new one. Take note of the screw size and buy a replacement screw.

Clogged Spring

The expanding foam gun's can adapter has a metal piece that holds the spray foam can in place. You can remove this metal piece using a mini-ratchet. Once removed, loosen the metal piece using a hex key to expose the spring.

Since this spring is part of the mounting mechanism of the gun, you'll most likely see it clogged with polyurethane foam.

The spray foam can may not fully engage if the spring has lost its tension. You can identify this problem if the can is too loose and if it wobbles if you attempt to snap the can into position. You can resolve this problem by replacing the spring.

Deformed Can Adapter

The can adapter can deform if it's accidentally hit or dropped on the floor. You can try to force the metal to its malleable state and bring it back to its original shape by gently heating the surface using a propane gas torch.

Faulty Trigger

The trigger can become jammed, making it difficult to activate the gun. To fix this, you will need to check the spring. The spring must have lost its tension or has eroded over time.

Broken Control knob

Another aspect of an expansion foam gun: the flow rate and foam output. Expanding foam guns come with various settings that allow them to shoot foam in different volumes.

But once the gun's setting is adjusted, there is a possibility that the foam will not keep shooting at a constant flow rate.

One of the most common causes of this is a malfunctioning control knob. This component determines the foam gun's output by adjusting the size of the gun's nozzle. If the control knob is defective, the foam gun may lose its ability to control the foam's output.

In this case, the user needs to look for the following signs to identify the problem:

- No foam coming out [nozzle stuck in close position]

- Unstable foam output

Sometimes, it's more convenient to buy a replacement gun than undergo the hassle of getting replacement parts and repairing it yourself.

Check out this expanding foam gun on Amazon.

How To Clean A Clogged Expanding Foam Gun

When you find that your expanding foam gun has become clogged, you need to first disassemble the gun. This means that you will need to pull out all of the parts. Remember how the parts fit together so you can easily put them back together.

After that, soak the parts in acetone until the hardened foam softens. This is necessary because you want to minimize the use of force scraping hardened polyurethane.

Applying unnecessary force can potentially scratch or damage delicate parts like springs and threads.

Check out this acetone on Amazon.

The video below demonstrates how to disassemble an expanding foam gun:

Expanding Foam Not Expanding - What Could Be Wrong?

The way expanding foam works is that it uses moisture as a catalyst that initiates foam formation. Moisture helps the other chemicals react with air and cause it to expand. This reaction leads to the expansion and curing of the foam.

If the expanding foam is not working as expected, it might be because the catalyst is insufficient. You can mist the area before you apply the expanding foam. This will allow some moisture to get into the mixture.

How Long Will It Take For An Expandable Foam To Expand On Average?

There is a misconception that expandable foam takes 24 hours to expand. The fact of the matter is that the expanding process only takes place in a matter of seconds after the foam is introduced into the air.

The 24-hour timeframe is just for the foam to fully cure and solidify.

What Is The Estimated Lifespan Of An Expanding Foam?

The foam is made up of polystyrene beads that are derived from petroleum. It is not a biological material, so it does not decompose or decay. You do not have to worry about it wearing out and breaking apart under normal conditions.

Is Expanding Foam Rodent Resistant?

Mice love to gnaw on insulation and other materials, and their droppings can harm the indoor environment. The rodents can also spread diseases such as salmonella, leptospirosis, and hantavirus.

To prevent mice infestations, homeowners must use proper pest prevention methods. Expanding foam can effectively serve as a barrier against mouse invasions.

It can be used as a sealant to seal cracks and holes that can potentially become passageways for them. However, mice can chew through it, but it will be a death sentence since expandable foam cannot be digested.

How Dangerous Is Inhaling Spray Foam?

Spray foam insulation is one of the most versatile forms of insulation available. It has many uses and benefits, but it also comes with potential risks, and most people don't know what the effects of inhaling spray foam are.

Inhalation of spray foam insulation can have scary consequences. Spray foam insulation is composed of polyurethane foam and other chemicals that can harm the body. Some of these chemicals include:

- Methylene diphenyl diisocyanate

- Polymeric methylene diphenyl diisocyanate

Inhalation of these chemicals can result in various respiratory impairments like dyspnea, asthma, and allergic reactions. If you or someone in your household develops breathing problems, consult your doctor immediately.

In Closing

Clogged nozzles are a significant cause of expanding foam guns not working. To fix this problem, first, make sure the nozzle is clean and has nothing in it. Second, check the trigger and pin assembly.

If either is broken, replace it immediately. Third, check the control knob for any cracks or damages. If any of these is damaged, you should get it fixed as soon as possible.

You might also like: