A safe and comfortable home brings satisfaction to homeowners. Cellulose insulation has low embodied energy and good thermal properties. However, it is not widely used in comparison to more traditional insulation materials. You might ask how long cellulose insulation lasts, as it is the less popular choice. We've researched this material to get an answer for you.

Cellulose insulation does not degrade quickly. Its average lifespan ranges from 20 to 30 years under controlled conditions, while the degradation starts at an estimated 15 years after the installation. Although, things such as severe weather forces can reduce its durability.

Cellulose insulation is one of the techniques used to fill in the hollows or cavities in the house's floors, walls, and other loose spaces. It is usually made of recycled newsprints, newspapers, or cardboard, and it is cheaper than the actual concrete. If you are interested in cellulose material for your insulation needs, keep reading to learn more!

Cellulose isn't the only type of insulation out there! If you're interested in which type is best in terms of longevity, check out this complete guide: How long does insulation last and when to replace it?

Considerations for Cellulose Insulation Uses

Below are guides before considering cellulose insulation, including various types of this insulation and where it is best installed.

Condition and Location of the House

We should understand that successful use of insulation begins with a comprehensive assessment of the house's condition. This will reduce the inconveniences we might encounter during the insulation process.

Climate & Moisture Level

We should consider the surroundings of our house. Are we located in a storm-prone area where the house is normally wet? Or is our house always under the heat of the sun where rain is rare?

Cellulose is composed of light materials, and a rainy day poses a problem since moisture will be absorbed by the paper mixtures and become too heavy for our attic. It might be time-consuming to dry out.

Building Materials

Is your house made of wood? Then cellulose can act as concrete if we apply it to wooden walls and floors. The softness of a paper could be turned into a solid rock-like component if the mixture is correct. But if your house is made of concrete, then the material can be additional protection to cover the damage and boost its firmness.

Leakage or Damaged Areas of the House

Check the area. There might be cracks behind the cabinets, damage to the ceilings, and holes under the appliances. If the floor sags noticeably, the joists may be rotten because their ends are built into rising, damp walls.

Inspect the pipelines if there are liquid leaks. Remember that covering faulty wires with cellulose can cause a fire. It is okay to inspect rather than skip parts that require repair.

Types of Cellulose Insulation

If our assessment leads us toward applying cellulose insulation, then we could now start to choose what type fits our needs. There are two popular types of cellulose insulation: dry fiber and damp fiber.

Dry Fiber Cellulose Insulation

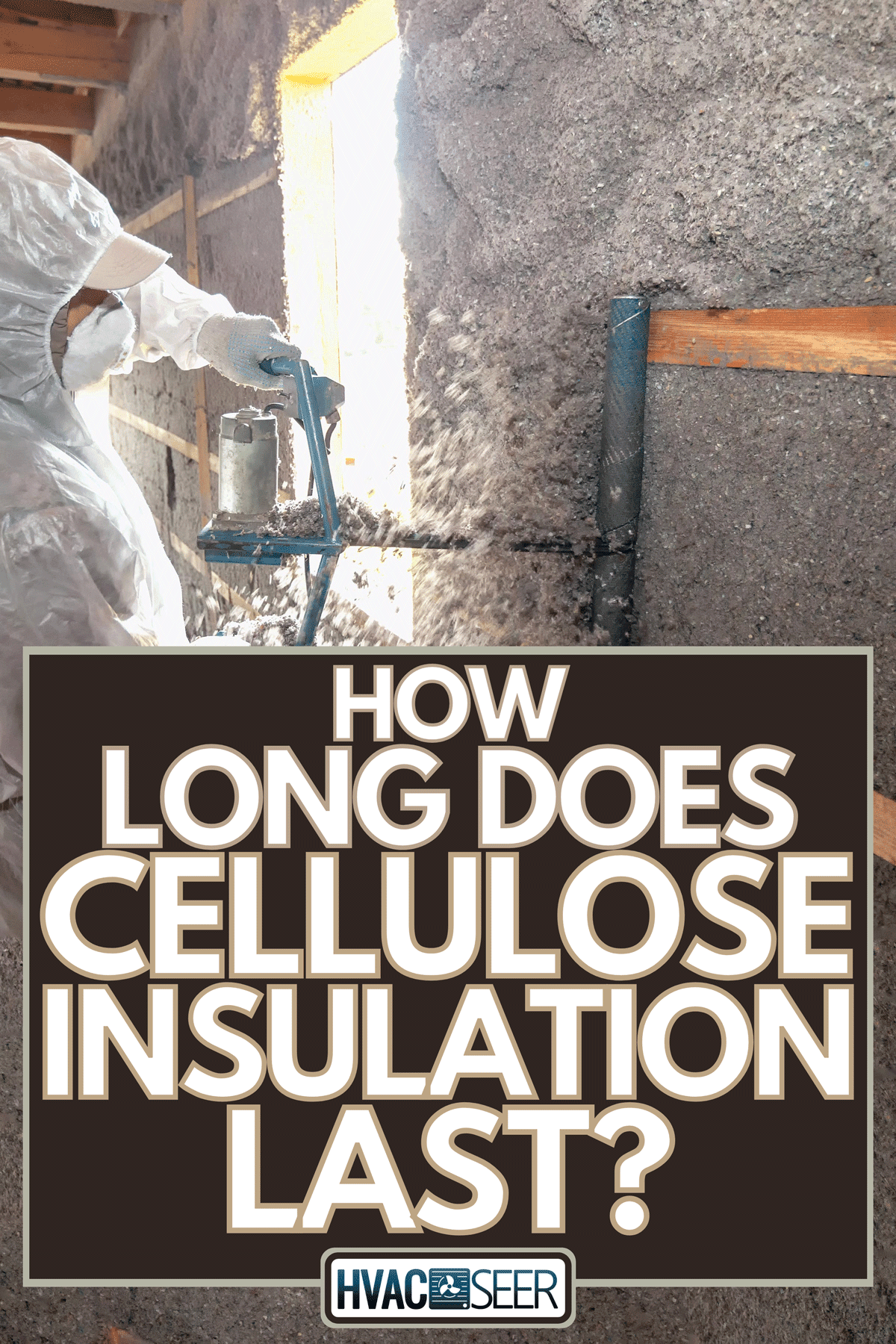

Dry cellulose is used in retrofitting old homes by blowing the cellulose into holes drilled into the tops of the walls. It can also be blown into a new wall construction by using temporary retainers or netting that is clamped in place and then removed once the cellulose has reached the appropriate density.

This technique is used with a blow dryer to fill in the hollows of the walls and floors. It is associated with heat and pressure.

Damp Fiber Cellulose Insulation

Damp fiber cellulose, on the other hand, is dampened with water, and a small amount of adhesive is blended in. It is like a cement-mixing procedure and shaping it into blocks or directly applying it to the surface.

After deciding what type of cellulose insulation is best for our home, now is the time to proceed with the completion of the process.

Quality Management for Cellulose Insulation

The mechanical deterioration rate of cellulose insulation is affected by the conditions under which it is used. Temperature, oxygen, and moisture are important factors. Here are a few things we should consider:

- Test a small amount first. Manufacturers are selling materials for cellulose insulation. Take time to read the formulation and instructions carefully, as they may differ in quality depending on the brand. Avoid substandard components in the mixture.

- Materials are made of shredded paper and dust. So, wear a mask to avoid inhaling harmful particles. Use eye protection, gloves, and preferably long sleeves to prevent irritation.

- Measurement should be accurate to avoid imbalances and uneven slopes. This will affect the flooring if you miscalculate and might result in an unequal volume of cellulose.

Does Cellulose Insulation Settle Over Time?

Cellulose dries towards the sheathing and loses half its moisture within the first 24 hours. It may take up to days or weeks to settle, depending on how deep we covered the area.

The higher the heat, the faster it settles. Rushing the installation can make it saggy and wasteful. So, we should balance heat and density.

Read more, here: "Does Cellulose Insulation Settle? How Much?"

What Is R-Value Cellulose Blown Insulation?

R-value, known as the resistance level of material on heat transfer and heat loss, indicates the ability of nearby objects to tolerate the movement of heat waves throughout the surfaces. Cellulose’s R-value ranges from 3.2 to 3.9.

Heat flows from the inside of the house to the outside during cold weather. By providing an effective resistance to the flow of heat, proper insulation in your home will reduce this heat flow. Shown below is the estimated R-value of cellulose based on depth:

| Material | R-value/

insulation |

3 1/2" | 5 1/4" | 10" | 12" | 15" |

| Cellulose blown (attic) | 3.2 - 3.7 | 11.2 - 12.9 | 16.8 - 15.0 | 32.0 - 37.0 | 38.4 - 44.4 | 48.0 - 55.5 |

| Cellulose blown (wall) | 3.8 - 3.9 | 13.3 - 13.6 | 19.9 - 20.8 | 38.0 - 39.0 | 45.6 - 46.8 | 57.0 - 58.5 |

The higher the R-value means the insulating power of a material is greater. Insulation that is dense enough to fill building cavities to reduce airflow can also reduce convection of heat loss.

Keep in mind that air sealing and moisture control are crucial for energy efficiency and health. Cellulose has a slightly higher R-value than fiberglass. Fiberglass batts and cellulose used in walls have similar conductive ratings of R-3 to R-4 per inch, depending on density.

Does Cellulose Insulation Need A Vapor Barrier?

It is not much needed, but we should use a vapor barrier on cold and wet areas like pool blocks and spas. By trapping air or gas between its pores, insulation restricts the movement of air. Water vapor is kept out of the wall cavity by vapor barriers such as sheets of plastic or craft paper. As a result, the insulation remains dry.

Read more here: "Does Cellulose Insulation Need A Vapor Barrier?"

Is Cellulose Insulation Mold-Resistant?

Mold can grow in humid areas if there isn't enough warmth. At the same time, water-soaked fibers are right up against wood studs and dry walls, which are prone to mold growth. It is sometimes sprayed with chemicals to make it fire-retardant and insect-proof, which also helps to prevent mold growth.

It’s simple to remove the damp fibers and allow them to dry for several days before reinstalling them. If mold grows, remove the damaged materials, clean the areas, and replace the insulation.

Final Thoughts

Cellulose insulation is fine, safe, and beneficial to our homes. It will last for many years if we take good care of it. Aside from finding the suitable type of insulation, we should consider the safety, location, weather condition, quality of materials, and the capacity of the area to support the insulation.

If we are not sure about the process, we can always consult an expert to evaluate the needs of our home and see if there are further repairs needed. The installation of this material should not be rushed but rather preceded by a thorough examination of the house's condition. If mold from an area can be cured by cleaning, then it can also represent an upcoming problem we should pay attention to—a tactical solution to combat any difficulties.