Heat is energy. Given its usefulness, heat can be uncomfortable at times. How can we reduce this thermal impact on our home? What insulation should we use, and how thick must it be? We've researched these questions to help you determine what is needed for your home.

Rated R30 insulation lowers heat conduction by 97%. The thickness needed ranges from 4.25 inches to 12.4 inches, considering the diverse materials. The insulation thickness varies on what material type you will use.

| INSULATION MATERIAL TYPE | R30 INSULATION THICKNESS |

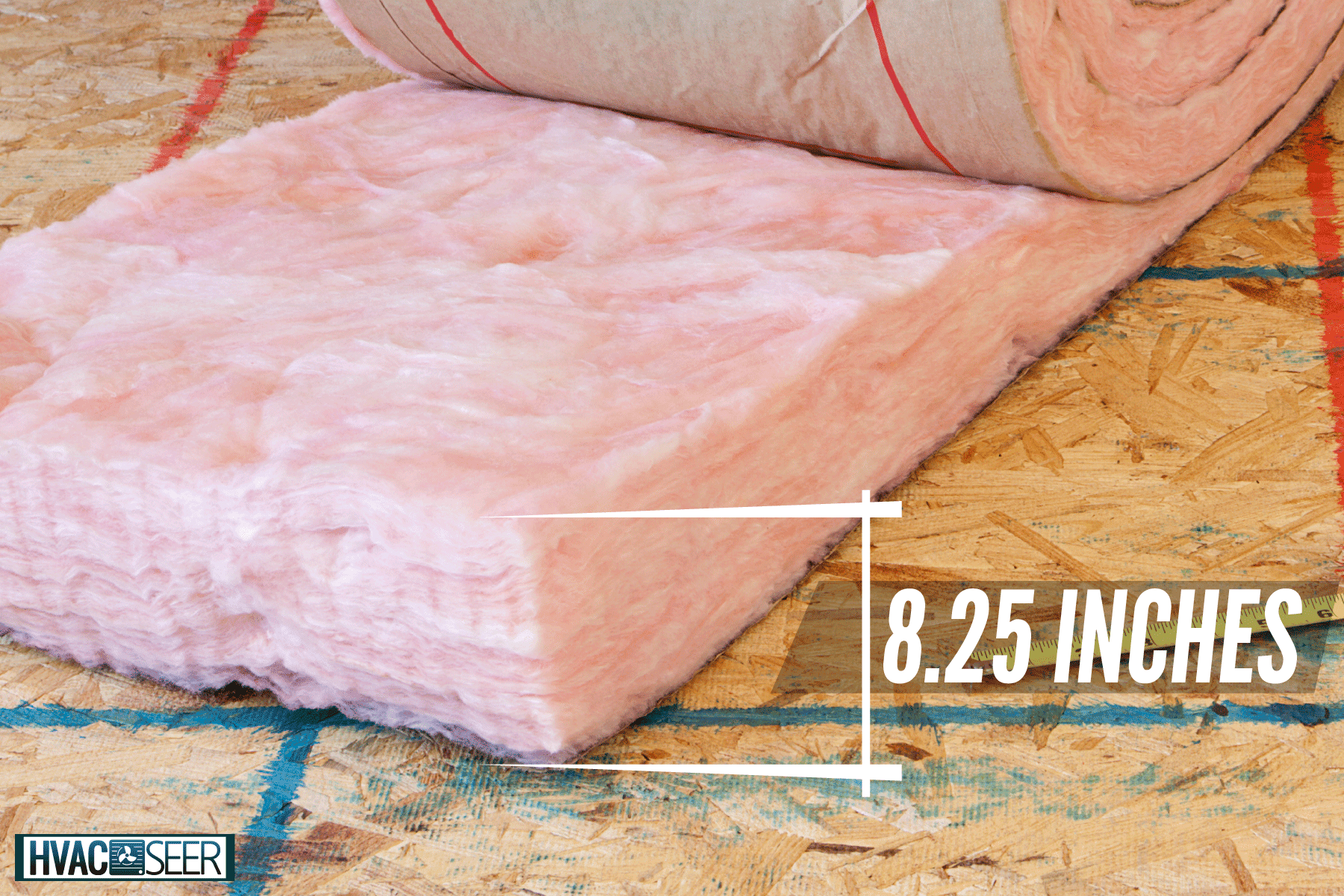

| Fiberglass | 8.25 inches |

| Open-cell Spray Foam | 9 inches |

| Closed-cell Spray Foam | 4.25 inches to 6 inches |

| Rigid Foam Board Insulation | 7.5 inches to 8.33 inches |

| Rock Wool Blown-in | 10.9 inches |

| Rock Wool Batt | 8.87 inches |

| Blown-in Fiberglass | 12.4 inches |

| Blown-in Cellulose | 9.3 inches |

The right R30 thickness will help you save money on energy bills. Let’s dig for more information to know which part of our house should use the proper R-value so that we can enjoy such benefits.

Insulation Thicknesses for R30 Value

The measurement of the material’s referred to as the R-value. Higher R-value means more energy efficiency. Heat flows in different mechanisms, so it must be ensured to block any possible heat migrations.

Fiberglass

It should be 8.25 inches thick to reach the R30 value. Made up of fine glass fibers, 80% of it is recycled glass. This insulator slows down the spread of heat, cold, and even sound. It can make a room cool when it's summer and warm when it's winter. This material traps air pockets and limits its movement losing about 40% of heat through conduction and convection or airflow.

Fiberglass Insulation Pros:

- Less expensive

- Can be a do-it-yourself (DIY) project

- Soundproof

- It can be placed in unfinished walls, floors, and ceilings

- Will fit between studs, beams, and joists

- Has no fire hazard

Fiberglass Insulation Cons:

- Small particles can cause irritation and rashes when they come in contact with skin and nosebleeds when inhaled.

- It can trap allergens and moisture as well which can lead to mold growth.

Spray Foam Insulation

You should choose which type of spray foam you will use if you think this is the best insulation for your home or structure.Open-cell and closed-cell spray foams are different in application, insulation thickness, and function in general. Unlike fiberglass, spray foam is not a DIY project.

| OPEN-CELL SPRAY FOAM INSULATION | CLOSED-CELL SPRAY FOAM INSULATION | |

| 9 inches | R3O Insulation Thickness | 4.25 to 6 inches |

| Lightweight, pliable | Structure | Rigid, very dense |

| High expansion rate (100 times) | Expansion Rates | Lower expansion rates |

| Water | Blowing Agent | Chemical agent |

| RetroFoam of Michigan | Spray Foams Used | RetroFoam of Michigan |

| Great sound dampening (quieter home) | Sound Dampening | Poor sound dampening qualities |

| Less expensive | Cost | More expensive |

| Permeable (water can move through it) | Moisture Permeability | Impermeable (holds water that may cause mold growth) |

| High shock absorption | Shock Absorption | Low shock absorption |

| Less durable | Durability | More durable |

| Mostly used in homes | Common Usage | Better suited pole barns with exposed walls |

Rigid Foam Board Insulation

To attain a R30 insulation thickness, a rigid foam board insulation must have 7.5 to 8.33 inches depth. Just like any other insulation, a rigid foam board insulation helps control indoor temperature and reduces a building’s energy bills. This is usually used on commercial structures. For a better insulating performance, use a foil facing.

Rigid Foam Board Insulation Pros:

- Water-resistant

- Can be buried to insulate exteriors of the foundation

- Has very high R-values than loose-fill insulation and the other foam options

- Can be used inside wall cavities

- Has flame retardants for fire safety

Rigid Foam Board Insulation Cons:

- Very reactive to sunlight, ultra violet rays can damage it

- A moisture barrier must be considered (on some installation locations).

Rock Wool Blown-in Insulation

A rock wool blown-in is heavier. It's hard to move it around, but it fills easier into the cavities of the wall because its heaviness reacts more to gravity. This must be 10.9 inches thick to reach a R30 Insulation thickness.

Rock Wool Blown-In Insulation Pros:

- Naturally fire-resistant

- No hazardous chemicals needed

- Suitable for drywall

Rock Wool Blown-In Insulation Cons:

- Too heavy

- Blown-in insulation reduces effectiveness over time

Rock Wool Batt Insulation

For R30 insulation, a thickness of 8.87 inches of rock wool batts should be used. This can be used in both wood and steel.

Rock Wool Batt Insulation Pros:

- Has noise reduction

- Fire resistant

- Mold, mildew, and fungi resistant

- Lightweight

- Elastic edges to perfectly fit into spaces

Rock Wool Batt Insulation Cons:

- Not biodegradable

- More expensive

Blown-in Fiberglass Insulation

The best result when using a blown-in fiberglass is when you use it on top of existing insulation. This improves the rating of the R-value if applied by 12.4 inches in thickness.

Blown-in Fiberglass Insulation Pros:

- More sustainable

- Best for hard-to-reach spaces in the attic

Blown-in Fiberglass Insulation Cons:

- Has irritants and is dangerous when in contact with the eyes and respiratory system

Blown-in Cellulose Insulation

Consisting of recycled paper, this installation requires a 9.3 inches thickness to attain R30 insulation.

Blown-in Cellulose Insulation Pros:

- Environmentally-conscious

- Fire resistant

- Generally cheaper

- Fewer health risk

Blown-in Cellulose Insulation Cons:

- Produces a large amount of dust during installation

- Absorbs moisture easily

- Needs vapor barrier

Where Do You Use R30 Insulation?

Proper R30 insulation installation gets indoor temperature under control. Its usage depends on classified climate zones. Different zones needed different R-values. We should know where R30 falls from these ranges and which part of our home structure needs a cooling down.

Climate Zones 1 to 3:

- Uninsulated attics

- Existing insulations of 3-4 inches

- Cathedral ceilings

Climate Zones 4 to 8:

- Floors

- Crawl spaces

- Cathedral ceilings

Is R30 Thicker Thank R19?

A lower R-value needs a higher R-value thickness. The R-value goes down when the chosen material is thicker. The larger the R-value, the better the insulation value.

Can You Use R30 Insulation In Walls?

Insulation is all about holding air in place to avoid heat flow. The amount of insulation and the amount of heat transfer have a direct relationship. Losing heat through wall insulation is also possible. The common R-values used for walls are R13 to R23, while ceilings and attic spaces prefer R30, R38, and R49.

To achieve 97% less heat conduction, it is important to pick the right material. Then, follow the adequate thickness needed from the range of 4.25 to 12.4 inches. Its properties must match your location’s climate zone and insulating area.

These types and measurements should correspond with each other to not just lessen the thermal impact but also to enjoy lower energy bills. Consider choosing the right material to match with the R30 insulation thickness your home should have.

Conclusion

The thickness of your insulation to attain an R30 value will depend on the insulation material you select and the area being insulated. Keep in mind that as R-values lower, insulation thickness increases. Better R-values tend to be larger, meaning the better job your insulative material will do!

For more insulation tips, check out our related posts: