Getting oil logged evaporator on your air conditioning system is sometimes frustrating but can be handled. Fixing this problem requires knowledge and detailed troubleshooting, so you better bring this matter to an HVAC technician to get the job done right. However, if you're feeling capable, we have researched an easy to follow ways to have your AC all back to normal in no time.

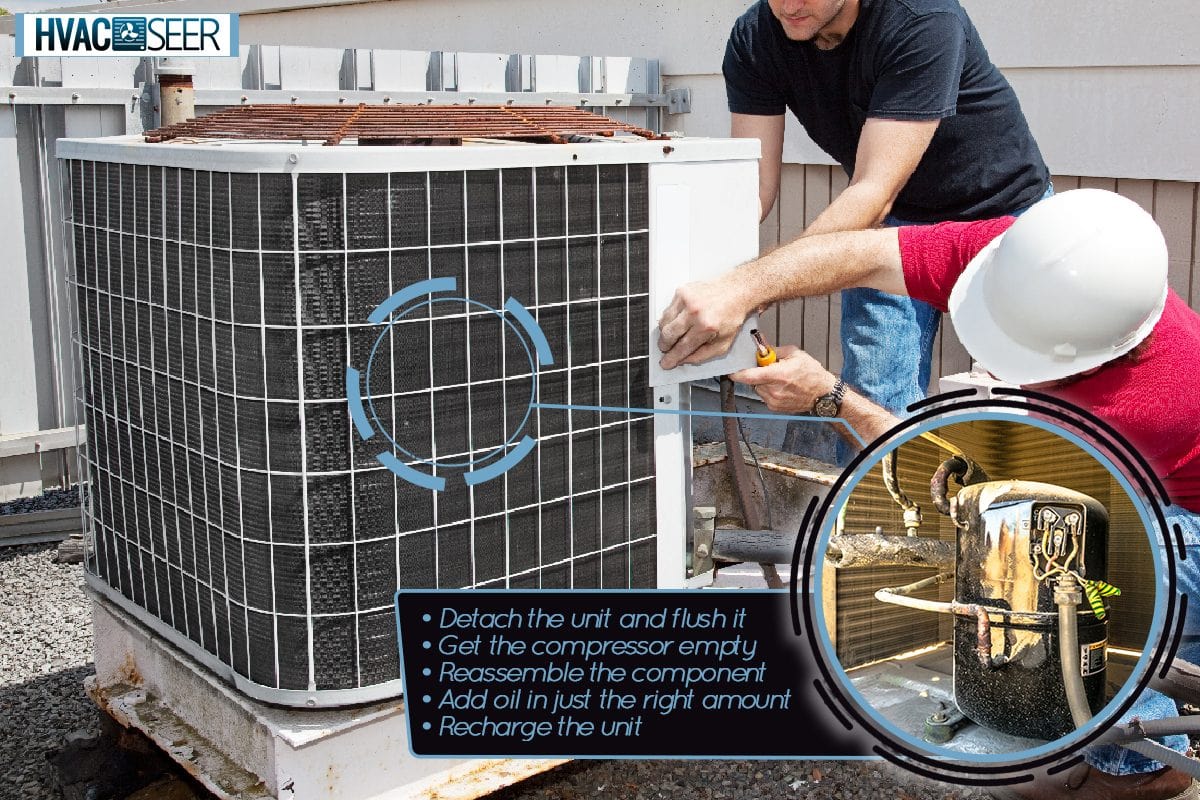

It is best to clean the evaporator coil and remove the excess oil from your HVAC system if you have oil logged. Installing a suitable oil separator or P trap can also help your evaporator avoid the same trouble again. You can follow these steps:

- Detach the unit and flush it

- Get the compressor empty

- Reassemble the component

- Add oil in just the right amount

- Recharge the unit

Read more for detailed instructions to have your evaporator get fixed. We will also discuss other factors that cause an oil migration to the evaporator and its symptoms to avoid further damage to your system.

What causes oil logged evaporator?

The building up of oil in the evaporator expansion valve may occur in two root causes: an excessive amount of compressor oil and the wrong type or viscosity of the oil. Either of the two can lead to poor system performance and may damage the compressor's mechanical parts.

An oil-logged evaporator can be either because of a flooded compressor, incorrect piping system, refrigerant migration, unadjusted TXV, or the wrong type of oil.

Refrigerant migration

Whenever there is a difference in pressure of the crankcase and refrigerant during the off cycle, the refrigerant travels back to the compressor's crankcase. The migration can cause the compressor to lose oil and flows to the refrigerant coil. The oil then gets caught in the evaporator, which causes oil logging.

Refrigerant flooding

Refilling or making up for the oil loss in the compressor oil reservoir can sometimes be too much. Thus, this excessive amount of oil in the compressor will migrate throughout the system along with the refrigerant. It then gets to the expansion valve and causes a restriction known as refrigerant flooding.

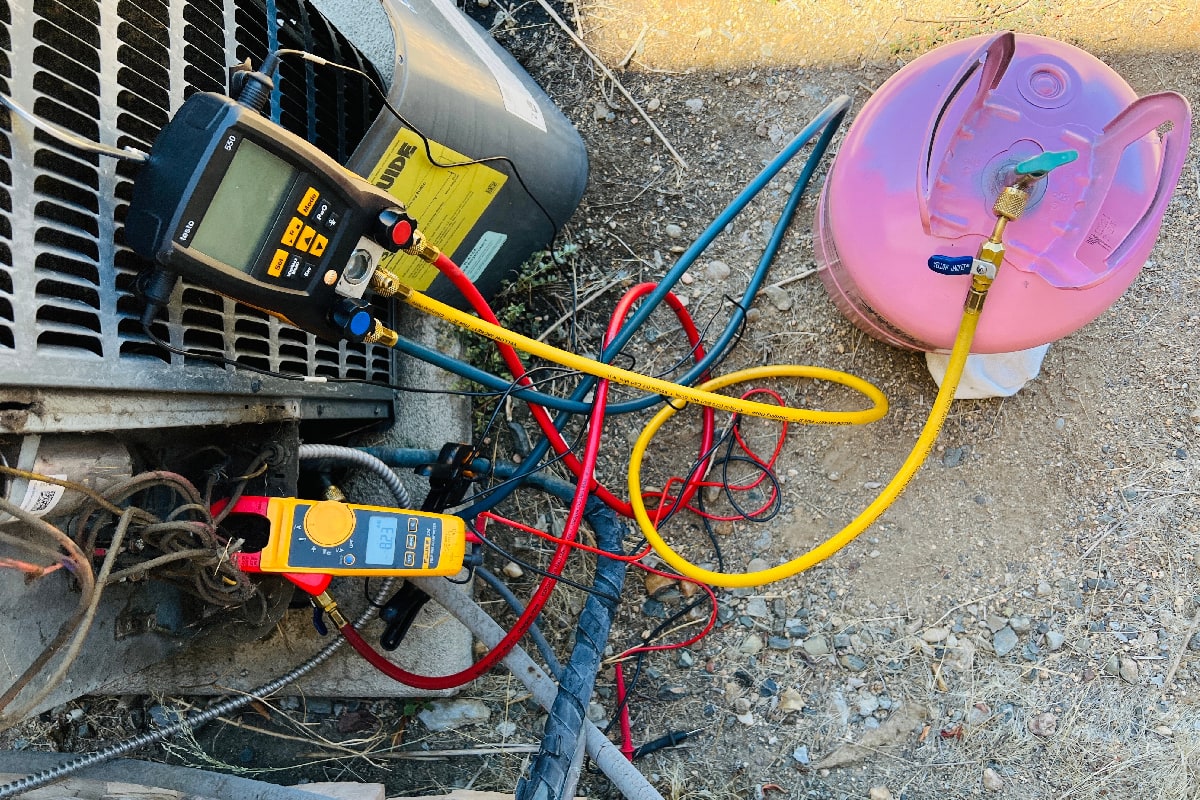

This phenomenon happens when the refrigerant goes inside the compressor and mixes with the oil, creating a foaming compound that goes through the system, leading to varying amounts of oil entering the valve. An HVAC technician can help you with normal pressure and temperature check and troubleshoot your unit.

Unsuitable type of oil in the system

Oil usage in a refrigeration system is to lubricate, reduce noise, friction, and mechanical wear, transfer heat, and seal valves. But the incorrect choice of oil might create a potential hazard to your system.

However, having too high oil viscosity will coat the coil's inner wall, leading to poor heat transfer performance. It happens in the evaporator, the coldest and largest tube in the system since it is where the slowest refrigerant velocity occurs. In addition, not enough oil will be circulating in the crankcase, which can lead to wear and tear of the components.

What to do with oil logged evaporator?

Not to mention other potential issues that may occur, cleaning by removing compressor oil from your HVAC system is the first thing to do to deal with your oil-logged evaporator. Follow these steps to clean your unit correctly and avoid chemical contamination.

Detach the unit and flush it.

It is advisable to disassemble the necessary components for better removal of oil since evacuation can only remove air and moisture in your coil. You can use nitrogen or quality chemical flusher and do air-compressed washing of the parts.

Get the compressor empty.

Then drain the compressor entirely by putting it upside down on a level surface for a few hours. You can also place a rag under to avoid stains. Don't forget to retrieve the refrigerant as it may harm the environment if not disposed of properly.

Reassemble the component.

Reassembling may be a little more tricky than dismantling, and refer to the manufacturer's manual when doing disassembly and reassembly. So, ensure you get the components back together in the right place.

Add oil in just the right amount.

The needed amount of your oil varies on your system's capacity. Also, use oil that best fits your unit. There are ways to know where you can find this information.

Recharge the unit.

Run your system to see if it works back to normal.

If cleaning your evaporator didn't solve the problem. Calling for a technician's help is better for further diagnosis. Installing P-trap and oil separator can also help prevent oil logged evaporator from happening again.

How do I know if my evaporator is oil logged?

Oil logged evaporator manifests evident symptoms. It can affect the temperature and pressure depending on the intensity of logging. Check these indications when your HVAC system is working.

- Noisy compressor. Lack of oil can cause the wearing of components that produces metallic sounds.

- Low oil level on the crankcase. Because of refrigerant flooding in the compressor, the oil is forced to migrate to the evaporator. You can check the sight glass of the compressor's crankcase for oil low level to proceed to needed remedies.

- TXV will have difficulty controlling superheat. The remote bulb of the TXV can show if too much oil is circulating in the system. However, poor heat transfers due to oil coating logged in the evaporator will get the TXV into trouble reading the accurate evaporator outlet temperature. It might also bring confusion to the technicians on the superheat reading and might do a misdiagnosis. It can also cause the total to superheat in the compressor to run lower.

- Higher box temperatures. Because of poor heat transfers due to oil coating in the inner tube, the compressor will then work harder to maintain the average box temperature. The flow rate and pressure in the evaporator will also drop.

Learn how to troubleshoot your refrigeration system by watching this YouTube video.

How do you prevent liquid migration?

Refrigerant migration happens when there is a vapor difference between the oil in the crankcase of the compressor and the evaporator. Depending on the mixed oil and refrigerant percentage, the effect could be mild to severe.

It is an excellent practice to keep the oil at a higher temperature than the refrigerant during the off cycle to prevent this scenario from occurring in your system. Various types of resistive crankcase heaters are typically placed to regulate the desired temperature, and exposure of components to an extremely low temperature may cause this method not to work effectively.

You can buy this Trane OEM Compressor Crankcase Heater on Amazon.

Another alternative is to permit a minimally controlled current to pass through the single-phase compressor's start winding and run capacitor during the off cycle. It will pump down most of the refrigerant when the unit is idle.

And lastly, the installation of the liquid line solenoid valve. The valve will be open when the system is working and automatically closes when it is off. It stops refrigerant from entering the evaporator coil simultaneously during the off cycle, not impeding regular operation.

You can buy this Liquid Line Solenoid Valve with Coil on Amazon.

It's crucial to avoid overheating the oil, regardless of the type or method used. For recommendations, always get in touch with the compressor manufacturer.

Final thoughts

Regularly check on too much oil in HVAC system indications and keep warmer than the refrigerant to prevent migration. Serious refrigerant migration can lead to wear and tear of the compressor, but there are ways to avoid it. The best thing to do is to follow the compressor and system's manufacturer's manual guidelines.

Choosing the right oil and viscosity for your unit is also essential. Low-viscosity oils are recommended because they are denser than the commonly used refrigerants, so they will settle down and not mix. Always consult your technician or manufacturer to confirm the amount and type of oil for that specific refrigerant before servicing your entire system.

Improving oil returns, such as installing crankcase heaters, can save your system from potential damage in the long run. Setting up a suitable oil separator or P trap can reduce the risk of oil retention and minimize oil accumulation.

Are you looking for more essential information on air conditioning maintenance? Check out these informative articles:

How to clean air conditioner coils?