When solving a leakage or gap problem in your home, you will find that hydraulic cement and expanding foam are among the usual options. Although both are effective, each works better depending on the purpose. Which one should you choose? For this post, we researched the pros and cons of hydraulic cement and expanding foam to help you.

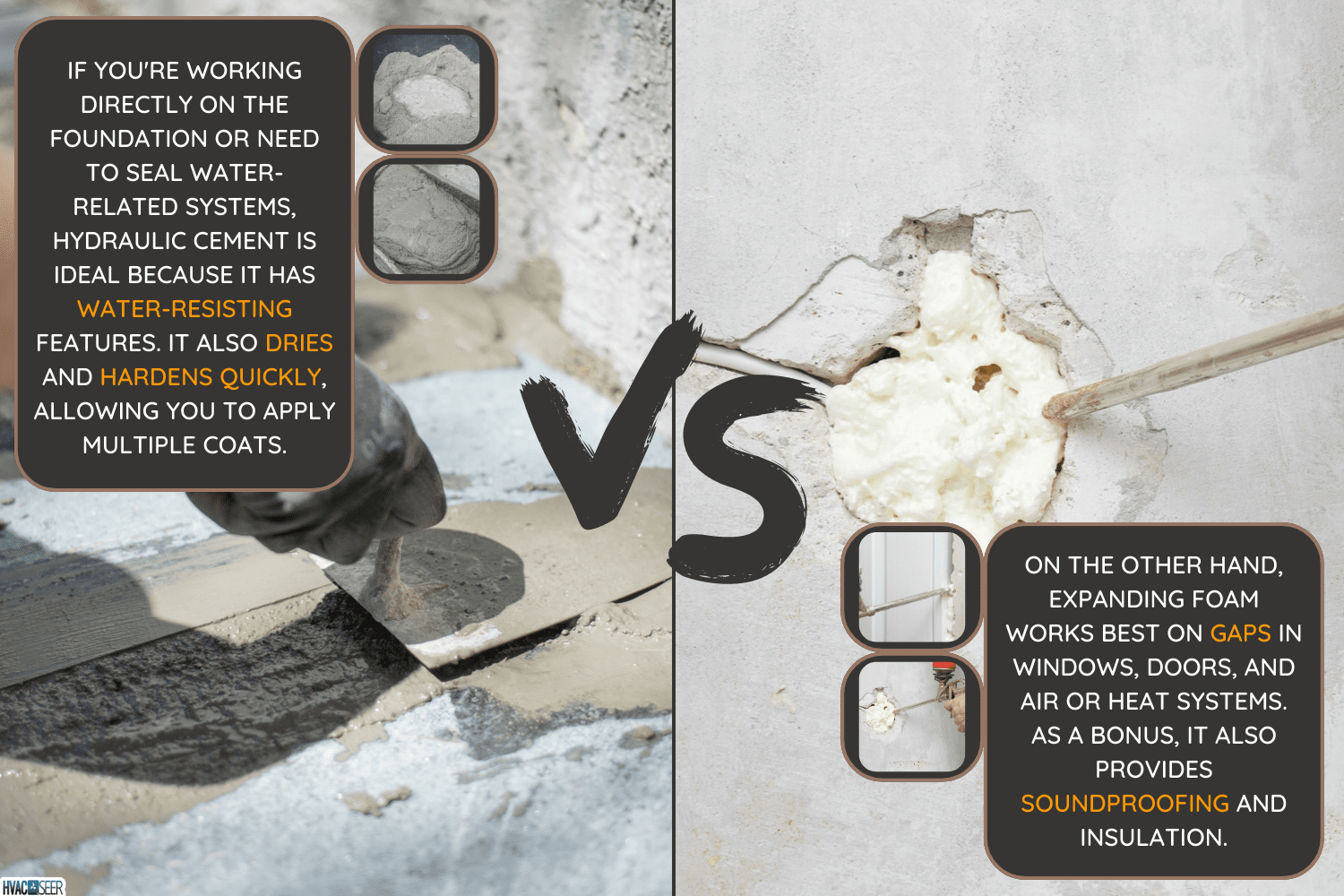

If you're working directly on the foundation or need to seal water-related systems, hydraulic cement is ideal because it has water-resisting features. It also dries and hardens quickly, allowing you to apply multiple coats.

On the other hand, expanding foam works best on gaps in windows, doors, and air or heat systems. As a bonus, it also provides soundproofing and insulation.

Hydraulic cement and expanding foam offer better performance depending on where you use them. Keep reading as we compare these options and elaborate on when you should use which.

Does Hydraulic Cement Work?

You can use hydraulic cement for repairing foundations, walls, and water systems like drainage and swimming pools. It's mainly favorable for its hardening properties and performance even when in contact with water.

Like other cement mixtures, hydraulic cement should be combined with water before taking effect. The mix usually sets in three to five minutes, so it's crucial to ensure correct and careful application before it dries.

Click here to see this hydraulic cement on Amazon.

Here's a deeper look into its pros and cons.

The Pros

The following are some of the advantages you can get from hydraulic cement.

Water Resistance

Professionals prefer using hydraulic cement in construction because it can withstand long periods of direct contact with water after drying.

So this cement works for several uses besides sealing and repairing. It's also ideal for homeowners looking for a waterproof seal.

Quick Drying

Hydraulic cement dries fast, usually taking less than 10 minutes to set after application. Completing a repair with it consumes less time because you can paint over it once it hardens.

Durability

In connection to its water resistance and quick-dry features, hydraulic cement provides durable repairs expected to last a long time. As a result, it's recommended for structures and other construction work requiring materials that maintain hold for years.

Cost Effective

Hydraulic cement is cost-effective because its easy to apply, requires few materials, and lasts a long time. You can purchase the mix in different measurements, making it available at affordable prices.

Little To No Change

The structure of hydraulic cement allows it to keep its shape, meaning it will not shrink, even in the long run. It also won't corrode or rust, despite being put under different conditions.

The Cons

Below are the disadvantages of choosing hydraulic cement for repair.

Requires Precise Application

While the quick-drying feature is convenient, it's also troublesome since you need to be precise during application. This can be challenging for beginners because it requires proper control.

Lacks Flexibility And Insulation

When applied, hydraulic cement holds a solid structure, so you should add it accurately if you want to fill gaps efficiently. Unlike other sealing options, it doesn't offer insulation, meaning you have to install it separately.

Ineffective In Cold Temperatures

Hydraulic cement won't work on surfaces below 40 degrees Fahrenheit. It's also crucial to ensure the temperature doesn't drop after application to avoid damage.

When Should I Use Hydraulic Cement?

It's best to use hydraulic cement if the needed repair regularly comes in contact with water, such as plumbing, or requires sturdy structure, like walls or flooring.

You can use hydraulic cement to seal non-concrete leaks, but there may be cases where the material may be too hard or dry too quickly for the job.

How To Apply Hydraulic Cement

Preparing and applying hydraulic cement is relatively easy but requires a lot of care. Here's how you can get started.

- Clean and dry the surface. Note that the temperature should be stable above 40 degrees Fahrenheit and the repair area should not be frozen.

- Enlarge cracks or holes that are too small or shaped inconsistently for better application.

- You can use a mechanical mixer if you own one. If not, follow the instructions provided with your cement.

- Mix the cement and water according to the manufacturer's recommendation. Blend it in small amounts or only enough for the repair to avoid wasting too much mixture.

- Upon achieving a putty-like texture, apply it to the gaps or cracks. Firmly press it into place until it fills up. It's best to work as fast as possible while maintaining accuracy.

- Leave it to dry and paint over it if necessary.

If you're using Drylok, read this post for a more detailed guide on how to apply it: How To Apply Drylok [A Detailed Guide For Beginners]

Is Expanding Foam Effective In Sealing?

Expanding or spray foam can seal leaks and gaps, such as small cavities, hard-to-reach spots, and around doors and windows. It has high versatility, so it applies well on other surfaces too.

As the name suggests, the main characteristic of the foam is its expanding properties, making it effective in filling cracks, so that you don't have to worry about missing a few areas.

The foam is also less solid than cement or caulk, meaning you can adjust it freely before it dries completely.

Check out the expanding spray foam on Amazon.

The following are further explanations of the pros and cons of expanding foam.

The Pros

Listed below are the benefits of using expanding foam.

Flexibility

Spray foam comes with expanding properties, making it flexible in filling cracks. It can take up the complete area of a gap, depending on how you apply it. The foam is also less structured, making adjustments easier to do.

Offers Insulation

Besides sealing, spray foam doubles as insulation material, making it a good solution for humidity control and soundproofing. These make it good for filling gaps in foundations as an added layer.

Energy-Efficient

The insulation benefit you get from expanding foam helps regulate heating and cooling throughout your home. At the same time, you can use it to seal your doors and windows to regulate temperature. As a result, you may save money and have a lower power bill.

Extra Layer Of Protection

Spray foam provides extra protection by creating a barrier and air-tight seal, preventing potential energy loss and damage from the elements. It helps with issues such as moisture, bacteria, and dust or pollen.

Prevents Mold Buildup

Expanding spray foam can hinder the formation of mold by maintaining humidity levels and blocking moisture. It can help repairs last longer without disruption from mold and other bacteria.

Read this post for a more in-depth look at expanding foam: Is Expanding Foam Waterproof, Heat Resistant, & Good For Insulation?

The Cons

The following are some of the drawbacks of spray foam.

Time-Consuming

Expanding foam takes much longer to cure than cement, taking up around eight to 24 hours, depending on the product and surface conditions. If you want to paint or install something over it, you should wait for it to set to keep its effectiveness.

Temperature Sensitive

Like other materials, spray foam is also sensitive to temperature levels and may not work in conditions that are too cold or hot. It's best to apply the foam when the temperature is stable.

Read more about the conditions for applying spray foam in this post: Spray Foam Temperature Settings [Cold And Hot Climate Issues]

Less Effective In The Long Run

When installed incorrectly, spray foam may be prone to shrinking, reducing the benefits it provides your home. Although it can last a considerably long time, different conditions can affect how well the foam holds up as time passes.

When Should I Use Expanding Foam?

Most recommend using expanding foam when dealing with narrow, hard-to-reach cracks. The foam can fill up the space even when applied with less accuracy.

Expanding foam is a good option is you want to add insulating features to the repair, such as on basement walls or draft windows.

However, remember that spray foam isn't always waterproof, so it may not work effectively on surfaces that are frequently in contact with water.

How To Apply Expanding Foam

Expanding spray foam is easy to apply, whether or not you're new to it. The steps you should take to use it are as follows:

- Clean the surface by sweeping or wiping off dirt and oil using a brush or cloth.

- Wear protective gear, including safety goggles and gloves.

- Read the foam's instructions before applying it for any extra steps.

- Screw on the nozzle, making sure not to apply too much pressure. Thoroughly shake the can.

- Lightly spray the surface with just enough water to moisten it.

- Turn the can upside down and place the nozzle in the gap.

- Carefully apply the foam. Remember that it expands, so don't worry about not filling the hole.

- Regularly shake the can and lightly moisten the foam after each application.

- Leave it to cure when you finish.

- After the foam sets, trim off the excess foam, smooth the surface with sandpaper, and paint or plaster it if necessary.

The Bottom Line

Experts recommend using hydraulic cement and expanding foam for repairs. But each works best for different reasons.

If you need a sturdy material that can resist water and corrosion, go for hydraulic cement. Consider expanding foam for narrower cracks and additional insulation and protection.

Regardless, both are affordable, easy to use, long-lasting, and seal leaks exceptionally well.