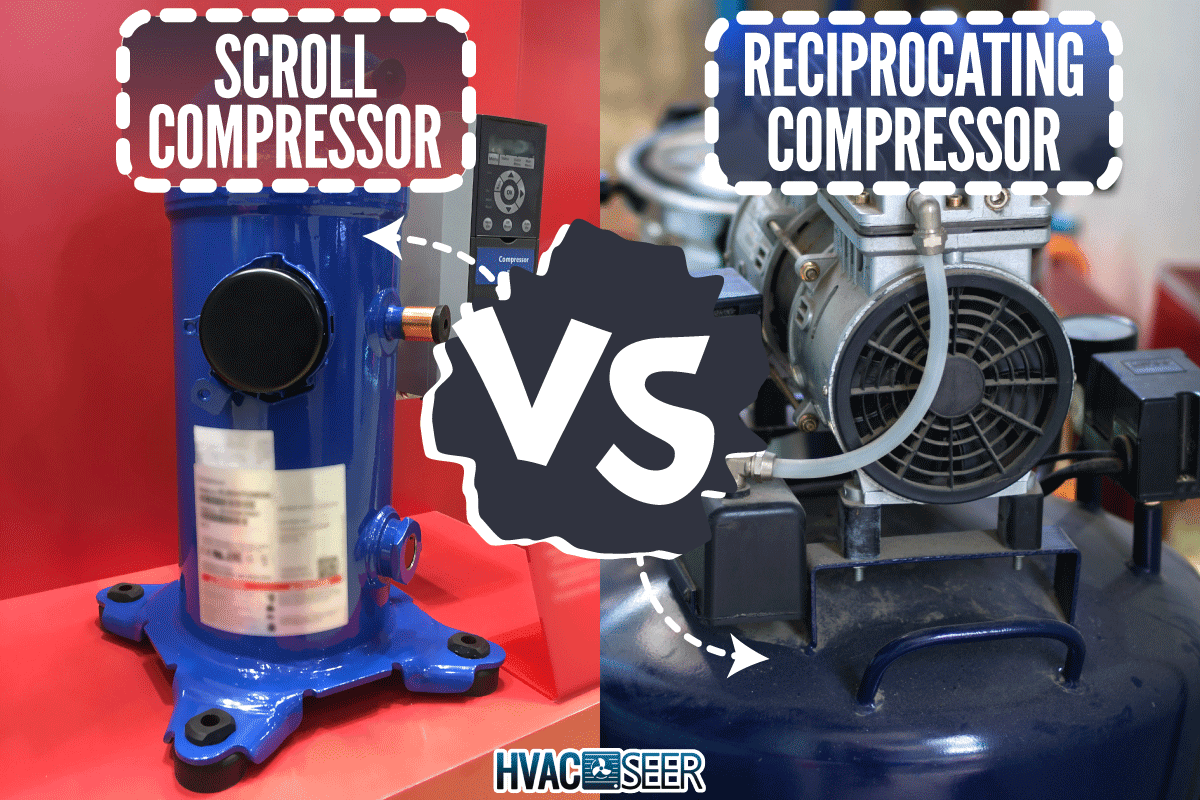

The compressor plays a significant role and is considered one of the most critical components of an HAVC system. The most commonly known compressor types are the scroll and reciprocating types.

So, we researched what style best suits your needs, and here is what we discovered.

You should go for a scroll-type compressor if you want something that produces minimal noise and vibration, is energy efficient, and is less susceptible to mechanical failure. These types are also the most widely used in residential HVAC systems.

But if you want a compressor that produces high-pressure gas and is highly efficient, then you should go for the reciprocating type. This type is frequently used in chemical plants, gas pipelines, natural gas processing facilities, and oil refineries.

To help you decide which compressor type suits you best, we'll present the pros and cons of each. To understand them better, we'll also discuss how these compressors work, their characteristics, and their types. So keep reading!

What Is A Scroll Compressor And How Does It Work?

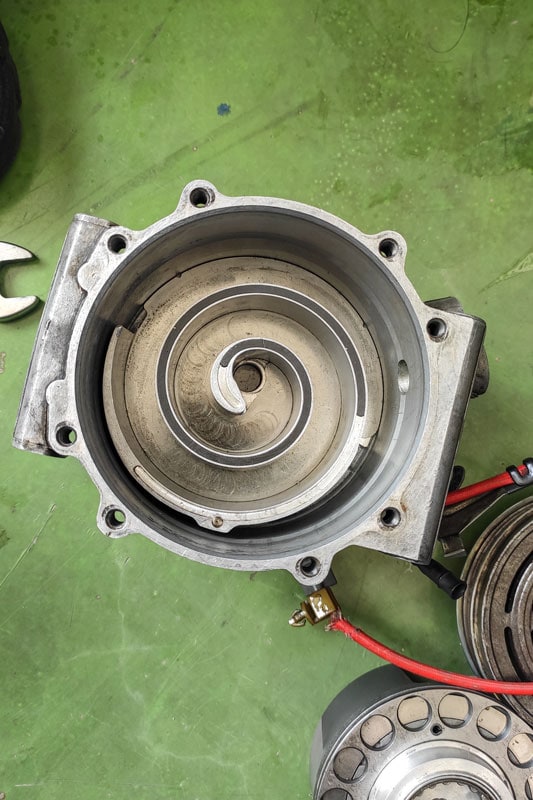

Unlike other compressors that use a piston to move up and down, a scroll compressor is a specially-made compressor that moves in a circular motion.

A scroll compressor has two scrolls: one fixed scroll that stays stationary and one rotating scroll that rotates through a swing link.

This causes the volume of the gas to decrease as the pockets of refrigerant between the two scrolls are gradually forced to the center of the two scrolls. After that, it is discharged to the condenser through the middle port.

What's The Difference Between Dual-Stage, Single-Stage, And Variable-Speed Scroll Compressors?

In this section, we will talk about the difference between these three categories of scroll compressors.

Dual-Stage Scroll Compressor

Scroll compressors with two stages work at two different speeds (high and low). As a result, they can better tailor their cooling output to thermal demands.

A dual-stage compressor can operate at a reduced speed, which increases its ability to remove moisture.

However, when necessary, the compressor can convert to full power, maintaining more constant temperatures while consuming less energy.

Single-Stage Scroll Compressor

Single-stage models are the most straightforward and affordable scroll compressors since they only have one speed.

In essence, a single-stage compressor always runs at total capacity. The compressor shuts off when the temperature inside the refrigerator reaches the set point.

The effect is that the compressor frequently turns on and off throughout the day.

Frequent on/off cycles cause uneven temperatures, wear and tear on system components, and increased energy usage.

Variable-Speed Scroll Compressor

These types run constantly and can adjust their operation up and down to accommodate varying thermal loads thanks to their various speed levels.

Modern variable-speed compressors can alter speeds in steps as tiny as 1/10 of 1% and offer up to 750 different operating speeds.

A variable-speed compressor can also improve the effectiveness of the overall refrigeration system because it doesn't repeatedly turn on and off.

Continuous operation may significantly increase energy consumption in systems that use single- or dual-stage compressors.

This is because variable-speed compressors have a higher part load efficiency than these two compression types.

What Are The Pros And Cons Of Scroll Compressors?

If you're curious about the advantages and disadvantages of these compressor types, here are some of them:

Pros

- Scroll compressors can achieve 100% volumetric efficiency without needing pistons, which results in lower energy costs.

- Re-expansion losses are eliminated, a common aspect of each piston stroke in reciprocating models. Since no suction or discharge valves exist, valve losses are also removed.

- Additionally, compared to other compressors, such as reciprocating type ones, scroll compressors operate much more quietly because they lack several moving parts. Scroll compressors often produce noise that is 5 to 15 dBA less than different compressor types.

- They do not require spring suspensions because there is less vibration and noise.

- These compressors are more resilient because they have fewer moving parts, experience less vibration, and experience less friction.

- In comparison to other, more substantial types of compressors already in use, their weight and footprint are far less.

- Additionally, gas pulsation is reduced, if not eliminated, allowing them to function with minimal vibration.

Cons

- Since scroll compressors are hermetic, their major drawback may be that they are frequently challenging to repair. For maintenance, they cannot be disassembled.

- Numerous reciprocating compressors can rotate in either direction. For scroll compressors, this is typically not the case.

- Additionally, incremental capacity management for systems with several scroll compressors has repeatedly been shown to be complicated.

What Is A Reciprocating Compressor And How Does It Work?

This is one of the most used types of compressors, and it compresses gas through the reciprocating motion of a piston. It manages low-mass but high-pressure ratios of gases.

The reciprocating compressor is built similarly to your vehicle or motorcycle engine.

The gas's absolute temperature at the inlet valve has an inverse relationship with the capacity of the cylinder in a reciprocating compressor.

The volume that enters the cylinder increases as the gas becomes cooler.

The piston's location at its highest point is referred to as the "top dead center (TDC)," and its position at its lowest point is the "bottom dead center (BDC)."

The reciprocating process involves taking a significant amount of gas from the suction line, compressing it using the piston's reciprocating motion, powered by the crankshaft, and releasing the compressed gas into the discharge line.

This component comprises a piston, inlet-outlet valves, a cylinder with appropriate cooling, a connecting rod, and a crank. To prevent gas leakage, the pistons are equipped with piston rings.

Both valves are made to operate quickly and without leaks. Through the connecting rod, the piston is attached to the crankshaft.

The crankshaft is driven by a prime mover, an engine, or a motor connected to a connecting road. This configuration converts the engine's spin into a piston's reciprocating action.

What Are The Pros And Cons Of Reciprocating Compressors?

Here are some of the benefits and drawbacks of these types of compressors.

Pros

- When compared to other types of compressors, a reciprocating compressor requires a lower initial investment.

- Reciprocating compressors work well in applications with sporadic use (not continuous).

- A reciprocating compressor is straightforward to build, and maintaining one is relatively simple.

- Even though a reciprocating compressor has more parts, the replacement parts are still reasonably priced.

- For applications under high pressure, reciprocating compressors are appropriate.

Cons

- It must be placed in a room with a solid base because of the high vibration and noise level.

- The compressed air's temperature at the discharge valve is high.

- Given the greater quantity of worn parts, maintenance downtime may be prolonged.

- These compressors are also sensitive to dirt.

- The issue of liquid is also quite important. Liquids must not be able to get stuck in low locations. Hence, suction piping must be designed accordingly. Liquids that gather in the piping's "pockets" can "slug" the compressor, seriously harming it.

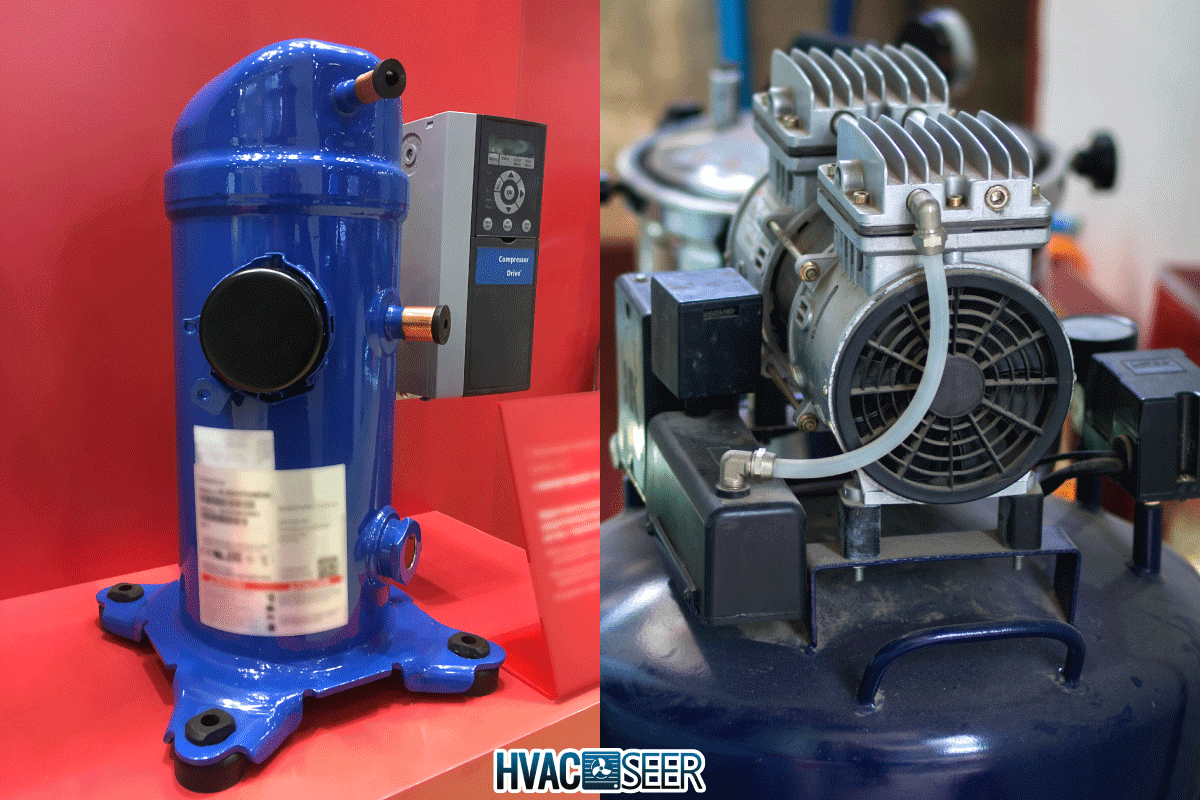

Scroll Vs. Reciprocating Compressors—Which Is Better?

The findings of a study conducted at Purdue University demonstrate that, in most cases, the cooling capacities and COPs of the scroll compressor are on par with or higher than those of the reciprocating compressor.

At the higher condenser temperature, the scroll compressor performs better than the reciprocating compressor.

The scroll compressor can achieve discharge temperatures that are lower than those of the reciprocating compressor thanks to the employment of a liquid injection mechanism.

Additionally, several tests were run to examine how both compressor types performed at various charge levels.

Regarding cooling capacity and COP about system charge level, the reciprocating and scroll compressors exhibit similar characteristics.

The scroll's cooling capacity degrades less quickly after overcharging than the reciprocating does. However, this is counterbalanced by the scroll's higher power consumption in an overcharged state, so the COP variance is comparable.

Undercharging typically results in a modest reduction in COP, but overcharging significantly reduces.

In Closing

You should use a scroll compressor for a quieter and less shaky compressor. Additionally, these compressors are energy-efficient and lightweight compared to other compressor types. However, these compressors are hard to repair.

On the other hand, you should go for a reciprocating compressor if you want a low investment cost. These compressors are perfect for high-pressure and sporadic use.

You should be careful, however, when using reciprocating compressors because they are pretty sensitive to dirt and produce high vibration and noise.

Before leaving, you can check out these other articles: